Large-diameter PHC tubular pile with double-layer reinforcement cage and preparation method thereof

A double-layer reinforcement cage and PHC pipe pile technology, which is applied to sheet pile walls, manufacturing tools, reinforcement molding, etc., can solve the problems of low reinforcement ratio and poor ductility of PHC pipe piles, and achieve a significant comprehensive effect and slow down the degree of yielding , Improve the effect of ultimate bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

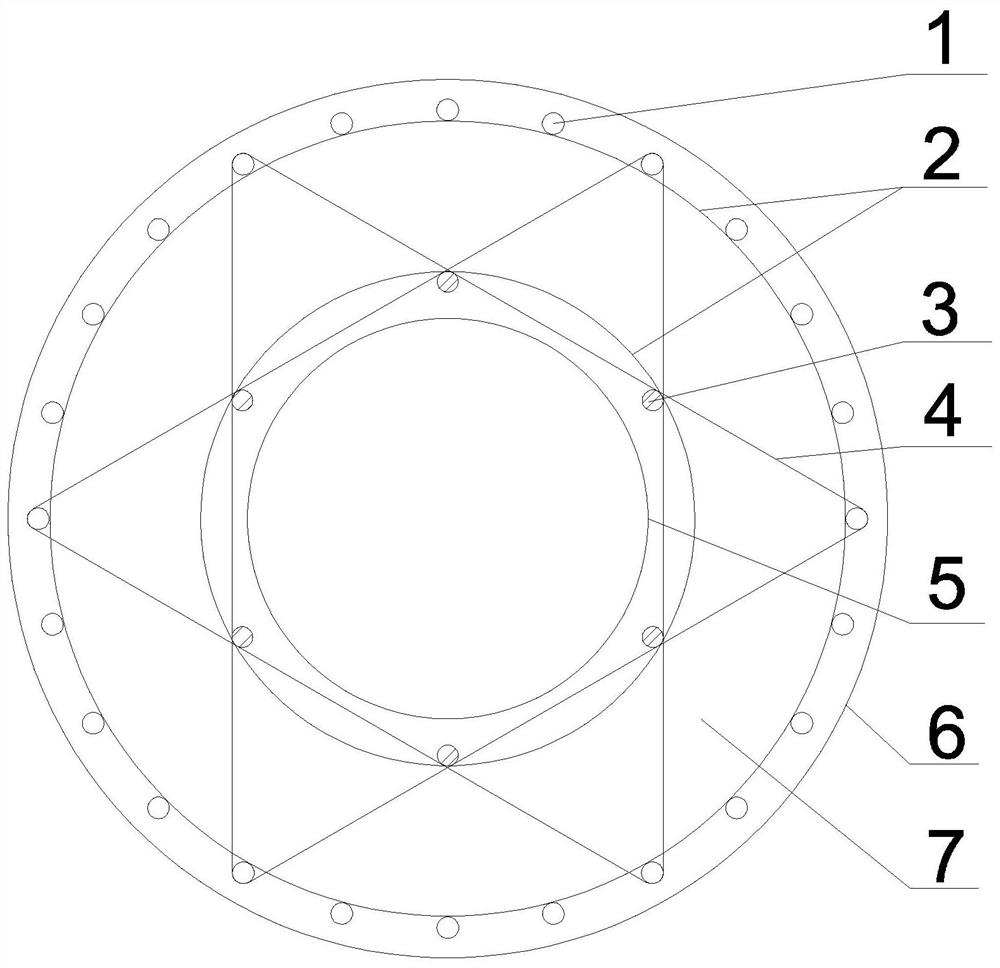

[0031] Specific implementation mode one: as figure 1 As shown, this embodiment discloses a large-diameter PHC pipe pile with a double-layer reinforcement cage, including a high-strength concrete pile body 7 with a hollow cavity, several ordinary steel bars 1, several prestressed steel bars 3 and several stirrup bars 2 ; The large-diameter PHC pipe pile of the double-layer reinforcement cage also includes several steel bars;

[0032] In the high-strength concrete pile body 7, there are several ordinary steel bars 1 distributed longitudinally and annularly near the outer wall 6, and in the high-strength concrete pile body 7, there are several prestressed steel bars 3 distributed longitudinally and annularly near the inner wall 5, and the several ordinary steel bars 1 Several stirrups 2 are bound on the inner side of several prestressed steel bars 3 and the outer sides of several prestressed steel bars 3, and several stirrups 2 bound on the inner side of several ordinary steel ba...

specific Embodiment approach 2

[0033] Specific implementation mode two: as figure 1 As shown, this embodiment is a further description of Embodiment 1, and the steel bar has a thickness of 5-8 mm in the cross section of the high-strength concrete pile body 7 .

specific Embodiment approach 3

[0034] Specific implementation mode three: as figure 1 As shown, this embodiment is a further description of Embodiment 1. The steel bar has a width of 8-12 mm in the cross section of the vertical high-strength concrete pile body 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com