High-stability (S)-4-hydroxy-2-oxo-1-pyrrolidine acetamide sustained release capsule and preparation method thereof

A technology of pyrrolidine acetamide and sustained-release capsules is applied in the directions of pharmaceutical formulations, nervous system diseases, and bulk transportation, which can solve the problems of poor particle fluidity, large differences in filling amount, and many particle powder layers, etc. The preparation process is simple and feasible, the number of doses is reduced, and the granules have good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A stable (S)-4-hydroxy-2-oxo-1-pyrrolidineacetamide slow-release capsule is prepared according to the following steps:

[0023]

[0024] Preparation process:

[0025] 1. Pretreatment of raw and auxiliary materials: take the prescribed amount of (S)-4-hydroxy-2-oxo-1-pyrrolidineacetamide, lactose, hydroxypropylmethylcellulose K4M, carnauba wax, calcium hydrogen phosphate, micro-powdered silica gel Put in the mixing pulverizer and mix and pulverize into fine powder (the amount that can pass through No. 5 sieve and can pass through No. 6 sieve must not be less than 95% of the total amount), and sieve;

[0026] 2. Granulation: Add povidone K30 ethanol solution, mix and granulate with 18-mesh sieve, place the prepared wet granules in a hot air oven, set the temperature at 40-60°C, and dry until the moisture content of the granules is ≤3%. Granules (through a 24-mesh sieve), set aside;

[0027] 3. Total blending: crush stearyl alcohol and magnesium stearate through a 100...

Embodiment 2

[0071] A stable (S)-4-hydroxy-2-oxo-1-pyrrolidineacetamide slow-release capsule is prepared according to the following steps:

[0072]

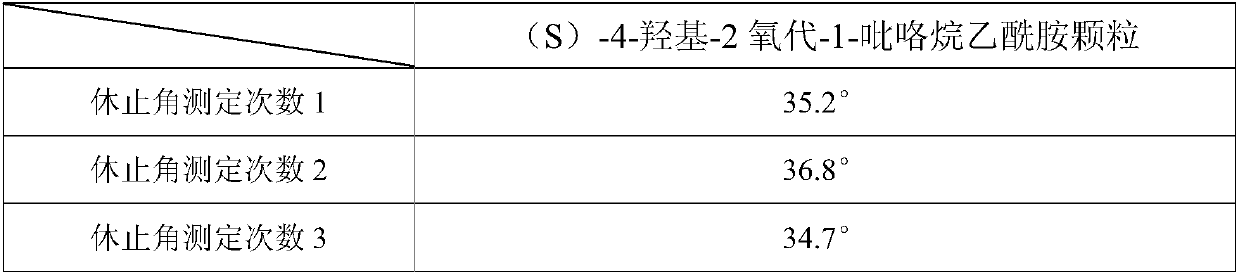

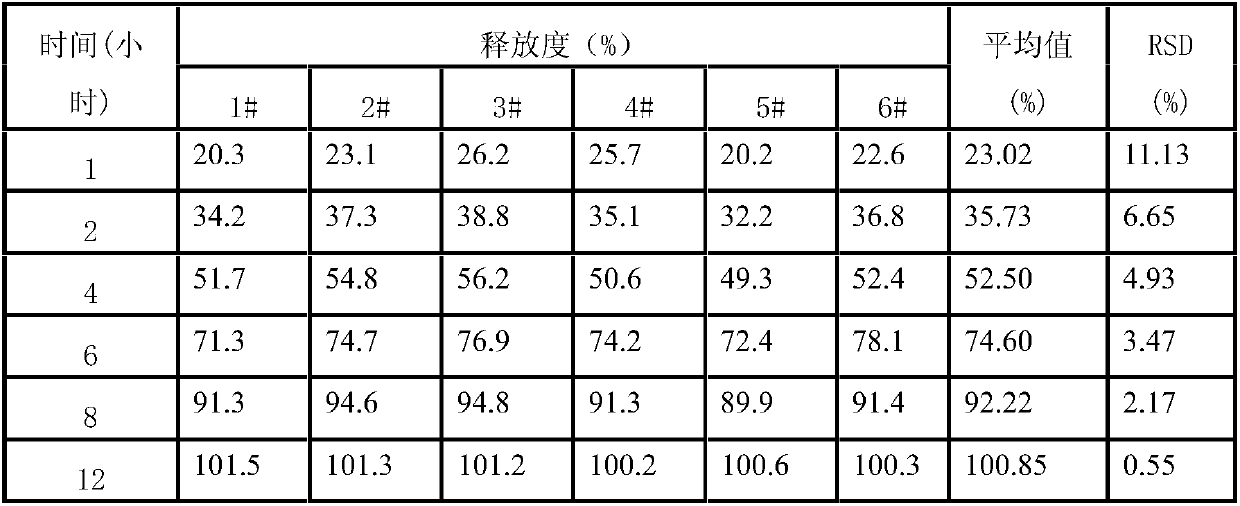

[0073] Preparation process: prepared according to the preparation process of Example 1. Test by the test method of Example 1, the yield test result shows that this product yield is up to more than 95%, the angle of repose result shows that this product has good fluidity, and the repose angle is less than 36 °, and the release measurement test result shows that (S)- 4-Hydroxy-2-oxo-1-pyrrolidineacetamide sustained-release capsules are slow-release, and the release time is as long as 12 hours, which can meet the requirements of sustained-release preparations. The results of the stability test show that the quality of the samples is stable after six months of acceleration. Capsule adhesion phenomenon, long-term 24 months of stable quality, no capsule adhesion phenomenon, so this product is valid for at least 24 months.

Embodiment 3

[0075] A stable (S)-4-hydroxy-2-oxo-1-pyrrolidineacetamide slow-release capsule is prepared according to the following steps:

[0076]

[0077] Preparation process: prepared according to the preparation process of Example 1. Test by the test method of embodiment 1, yield test result shows that this product yield is up to more than 94%, and angle of repose result shows that this product fluidity is good, and angle of repose is less than 38 °, and release measurement test result shows (S)- 4-Hydroxy-2-oxo-1-pyrrolidineacetamide sustained-release capsules are slow-release, and the release time is as long as 12 hours, which can meet the requirements of sustained-release preparations. The results of the stability test show that the quality of the samples is stable after six months of acceleration. Capsule adhesion phenomenon, long-term 24 months of stable quality, no capsule adhesion phenomenon, so this product is valid for at least 24 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com