Energy dissipating mechanism for wall

A wall-together technology, applied in the field of wall energy-dissipating mechanisms, can solve problems such as low energy consumption efficiency and unsatisfactory shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

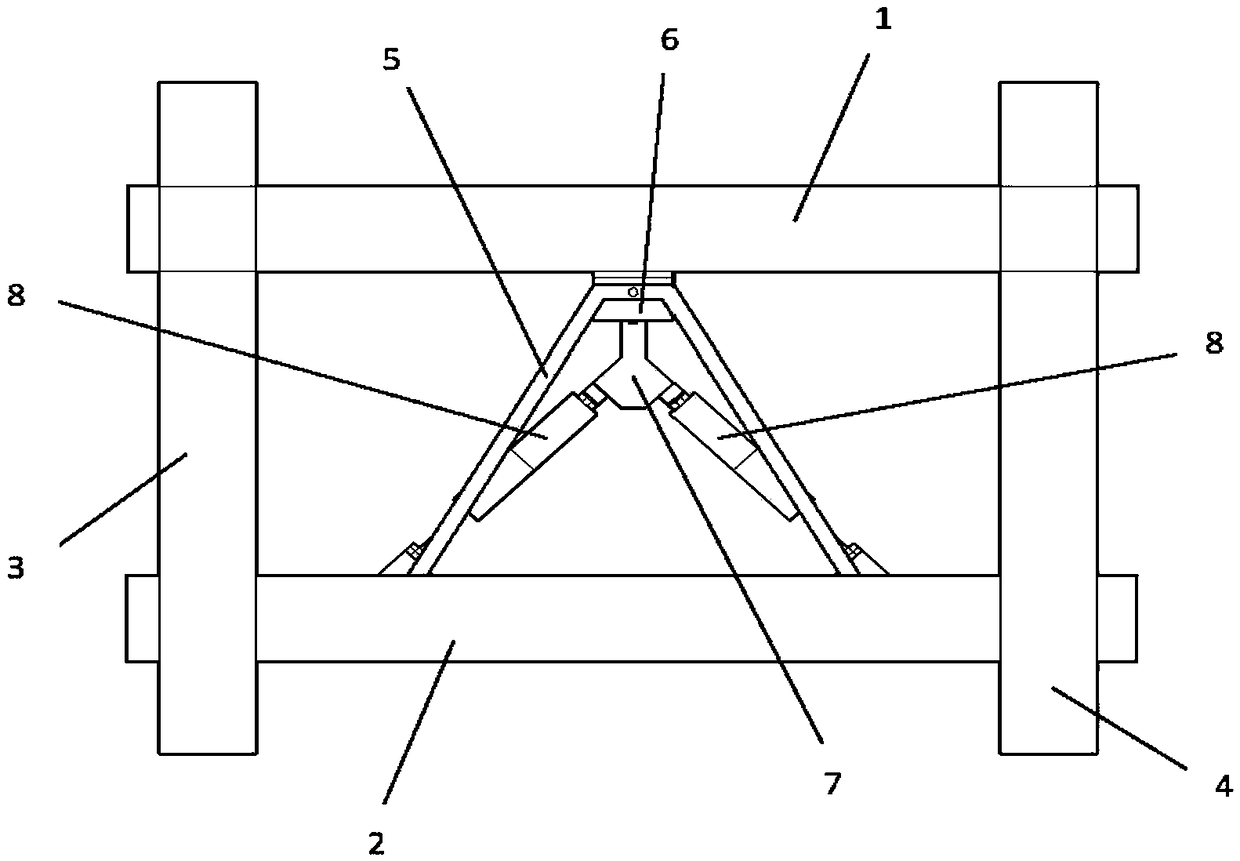

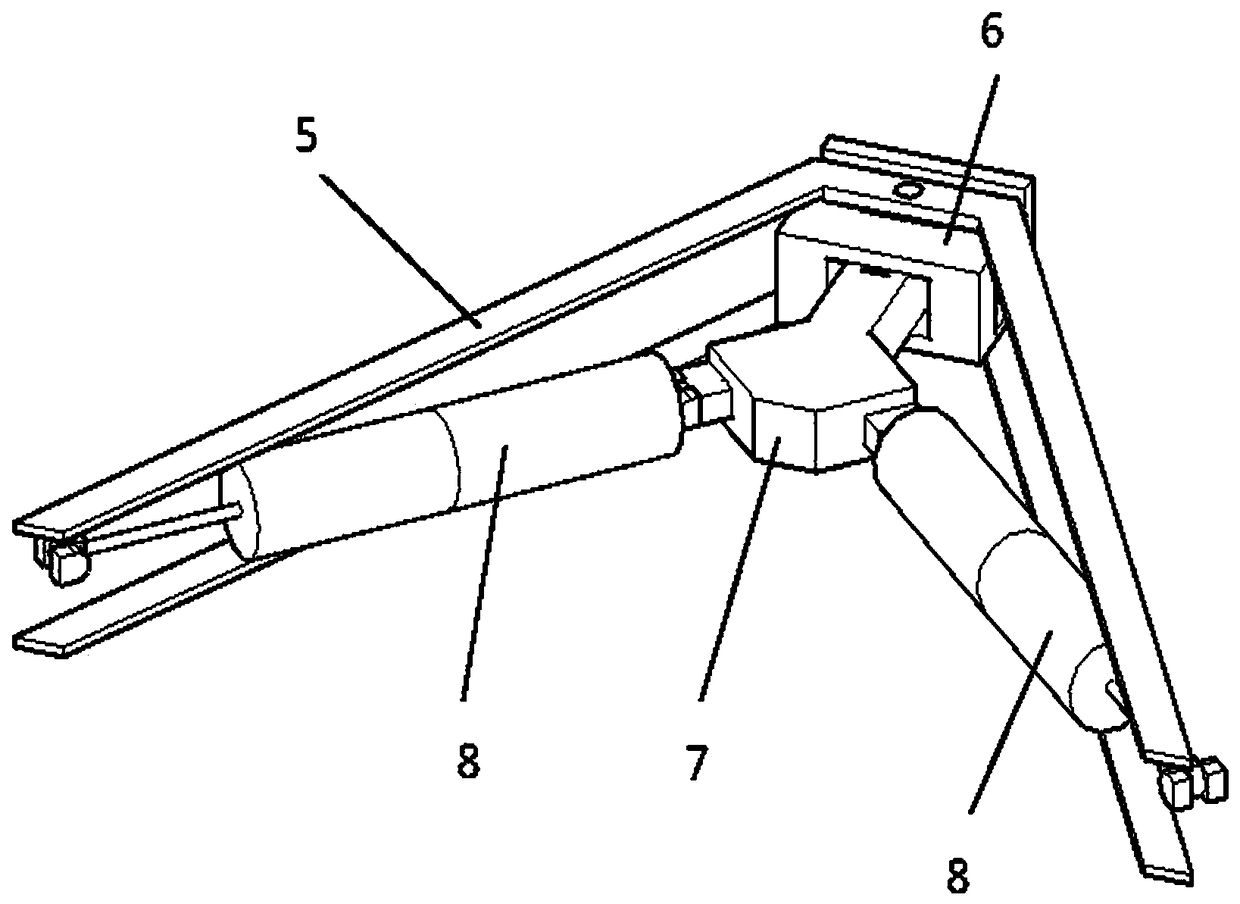

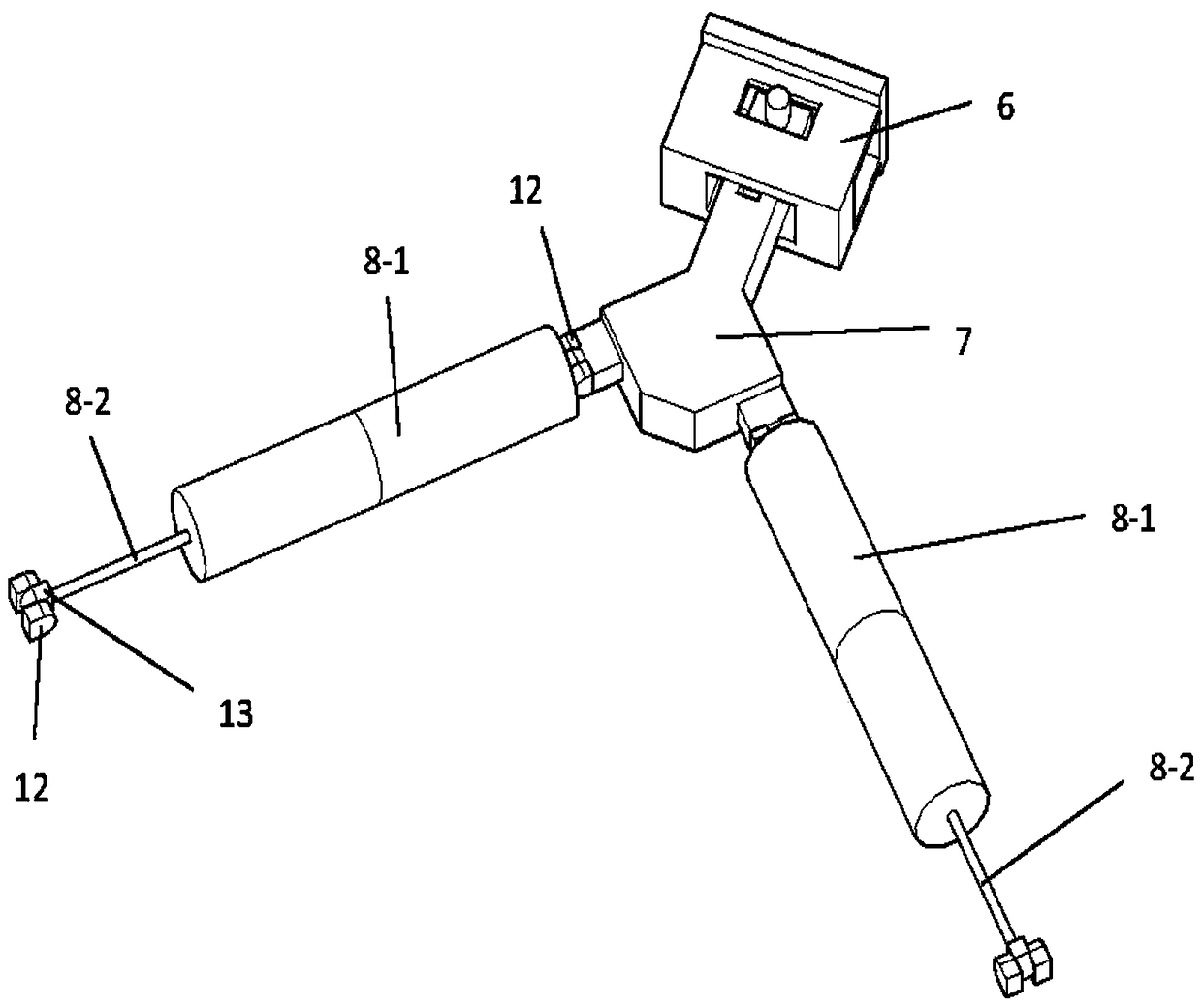

[0026] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0027] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

[0028] 1 is the upper beam, 2 is the lower beam, 3 is the left column, 4 is the right column, 5 is the bracket, 6 is the bearing block, 7 is the swing bar, 8 is the viscous damper, 9 is the first connecting shaft, 10 is the The second connecting shaft, 11 is the slider, 12 is the hinge support, 13 is the hinge block, 14 is the fixed seat, 5-1 is the first inclined plate, 5-2 is the horizontal plate, 5-3 is the second inclined plate , 5-4 is the bottom plate, 6-1 is the upper plate, 6-2 is the lower plate, 6-3 is the front vertical plate, 6-4 is the rear vertical plate, 6-5 is the gap, 6-6 is the lower plate 6-7 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com