Damping mechanism of upper and lower beam connection

A shock-absorbing mechanism and connection technology, which can be used in earthquake-proof, building components, building types, etc., and can solve problems such as low energy consumption efficiency and unsatisfactory shock-absorbing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

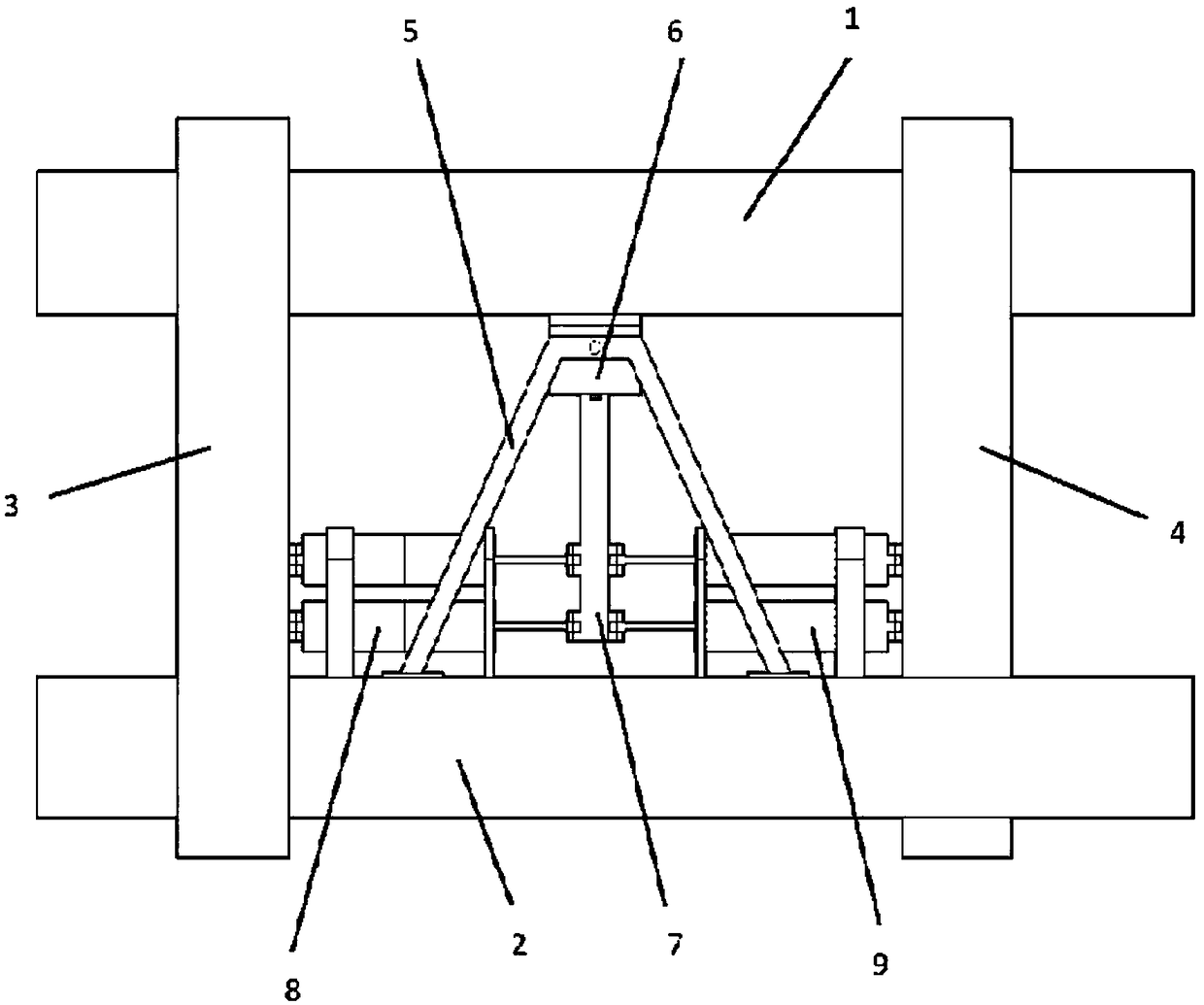

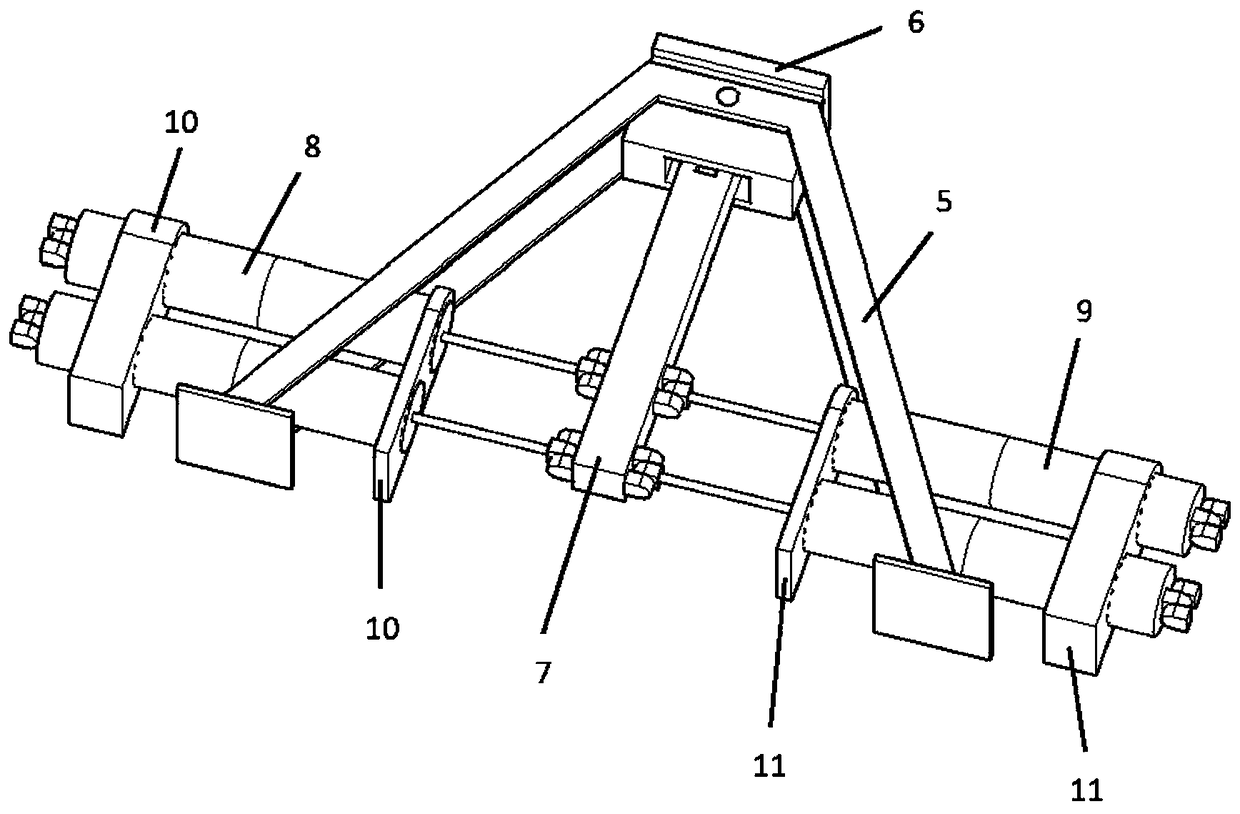

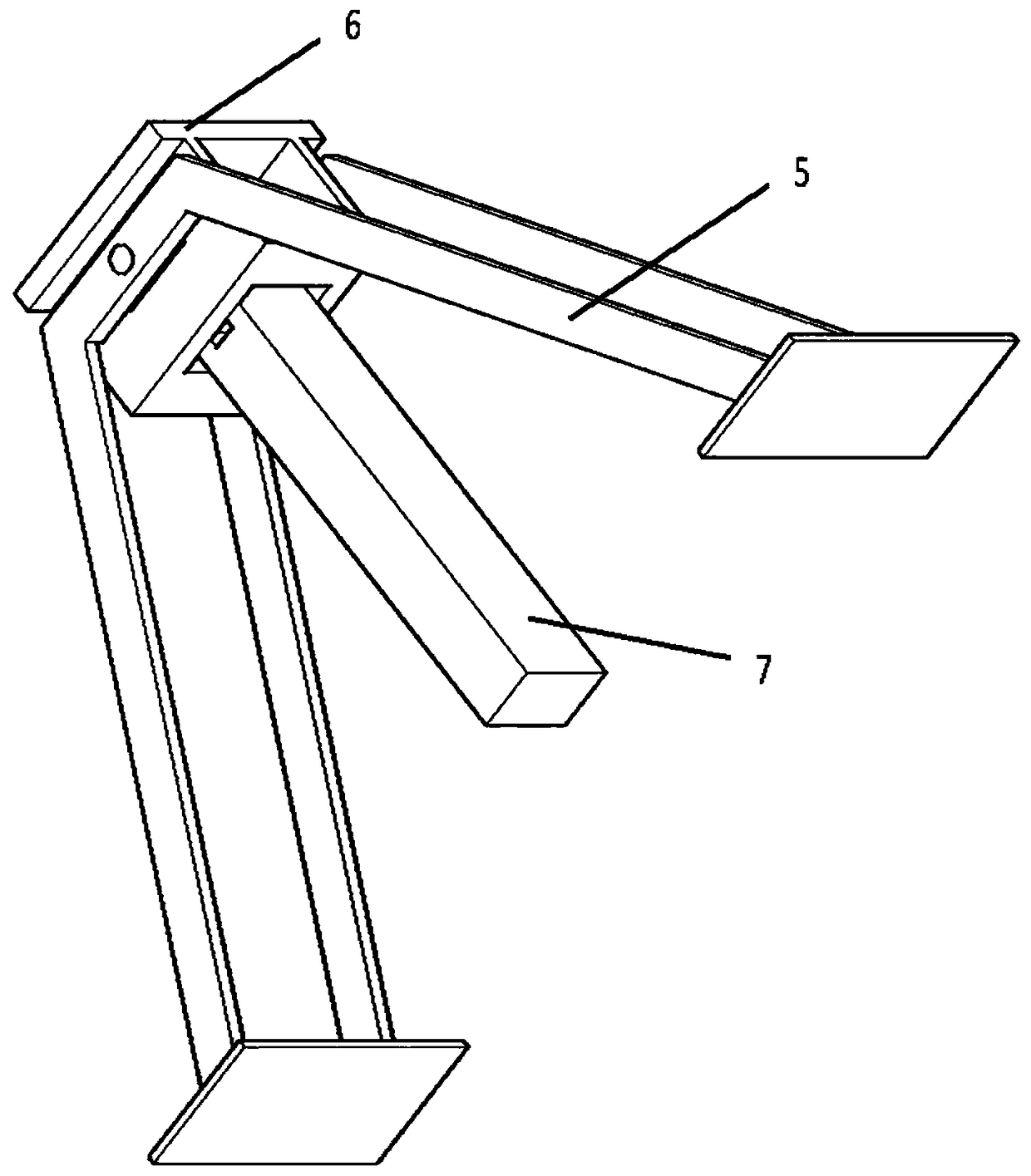

[0027] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0028] In order to facilitate the unified view of the various reference signs in the drawings of the specification, the reference signs appearing in the drawings of the specification are described as follows:

[0029] 1 is the upper beam, 2 is the lower beam, 3 is the left column, 4 is the right column, 5 is the bracket, 6 is the bearing block, 7 is the swing bar, 8 is the left viscous damper, 9 is the right viscous damper, 10 is the left support guide block, 11 is the right support guide block, 12 is the hinge block, 13 is the hinge support, 14 is the first connecting shaft, 15 is the second connecting shaft, 16 is the slider, 5-1 is the first Inclined plate, 5-2 is the horizontal plate, 5-3 is the second inclined plate, 5-4 is the bottom plate, 6-1 is the upper plate, 6-2 is the lower plate, 6-3 is the front vertical plate, 6-4 Is the rear vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com