Multi-layer anti-blast protection structure on ship side

A protective structure and ship technology, applied in the direction of ships, hulls, ship construction, etc., can solve the problems affecting the maneuverability of ships, increasing the weight of ship hull structures, etc., to achieve light structure, simple structure, and enhanced impact resistance and damage resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

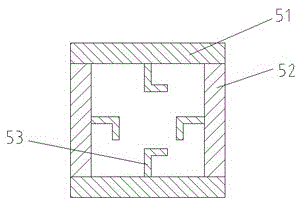

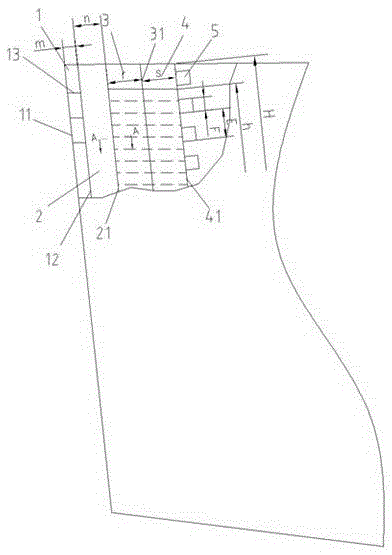

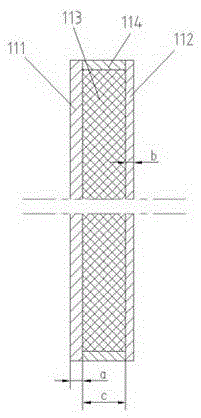

[0023] Such as Figure 1 ~ Figure 3 As shown, the present invention includes a double-layer shell 1, an empty compartment 2, a first liquid tank 3 and a second liquid tank 4 arranged sequentially from the outside to the inside of the ship hull, and the double-layer shell includes a shell plate 11, a second shell The plate 12 and at least three layers of longitudinal partitions 13 fixed between the shell plate 11 and the second shell plate 12 at intervals up and down, the liquid filling height h in the first liquid tank and the second liquid tank are both 0.70-0.80 of the tank height H, The water filling height h in the first liquid tank 3 and the second liquid tank 4 in this embodiment is both 0.75 of the tank height H. At this time, the anti-knock capability of the hull structure is consistent with that of the first liquid tank 3 and the second liquid tank 4 when they...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com