Suspended-dome multi-time prestressed construction method

A suspend dome and construction method technology, applied to roofs, building components, buildings, etc., can solve the problems of inconvenient selection of components, uneven distribution, waste of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

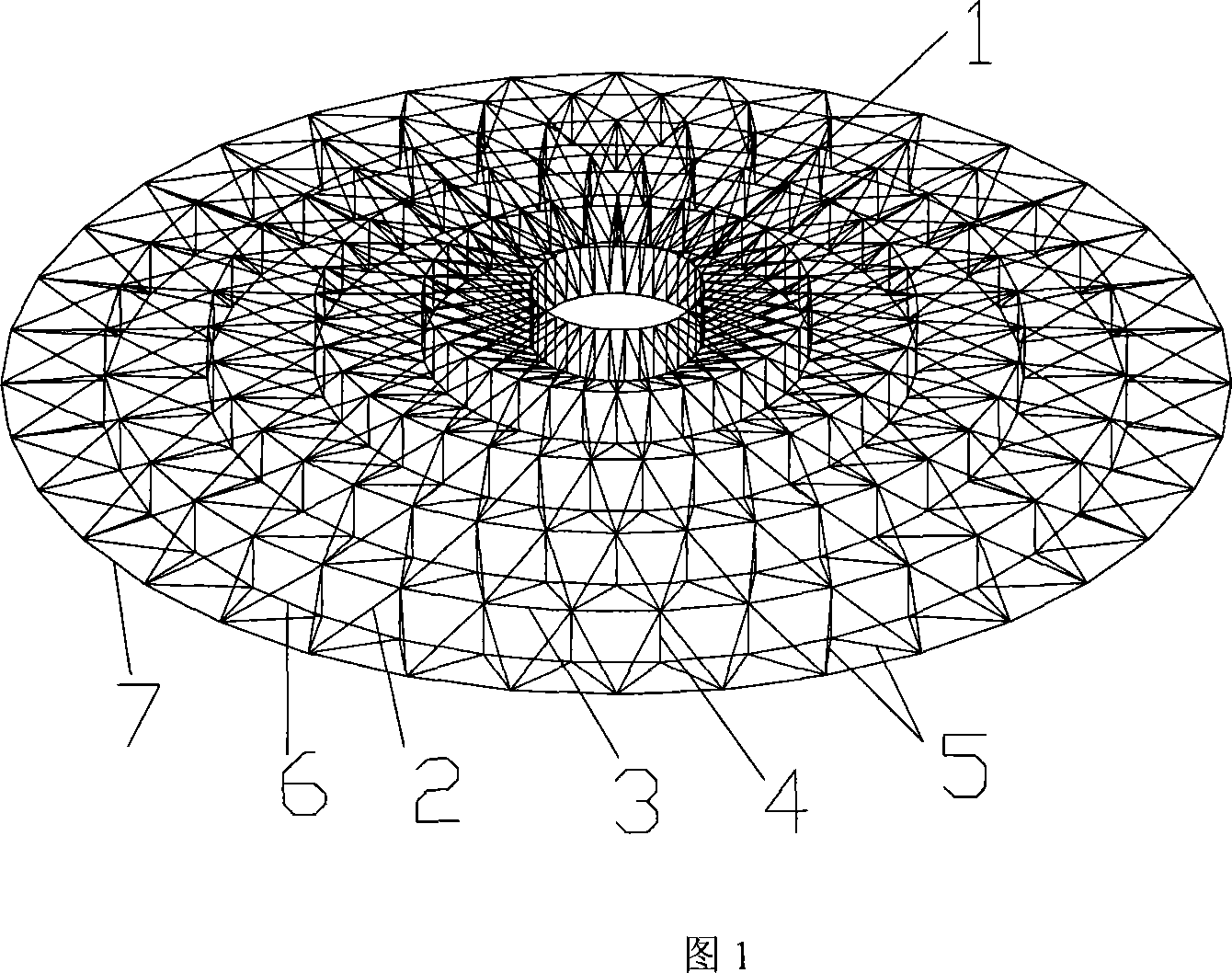

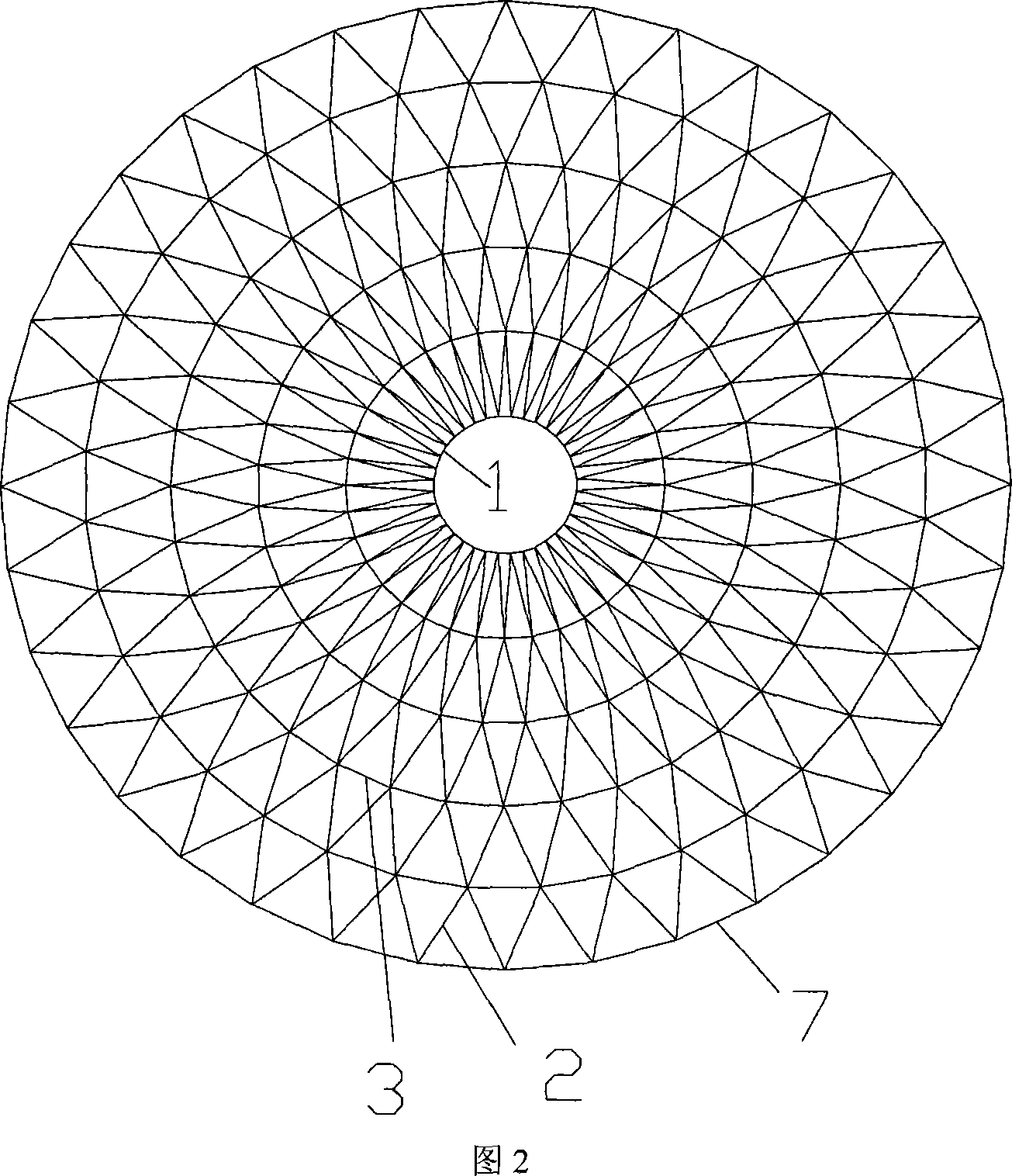

[0028] As shown in Fig. 1, Fig. 2, Fig. 4, Fig. 6 and Fig. 7, the construction molding process of this embodiment is as follows: the first step is to install the upper central pressure ring 1, the upper radial rod 2, and the edge member 7 to form a The structure of the upper reticulated shell is shown in Figure 7. The specific installation method is: first install the edge member 7, and then install the upward radial rod 2 in the order from inside to inside, one end of the upper radial rod 2 on the outermost ring is connected to the edge member 7, and the other end is connected to other upper diameter rods The radial rods 2 are connected end to end, one end of the innermost upper radial rod 2 is connected end to end with other upper radial rods 2 , and the other end is connected with the central pressure ring 1 . It is also possible to install these components in the reverse order, or follow the construction sequence from the inside to the middle at the same time.

[0029] Th...

Embodiment 2

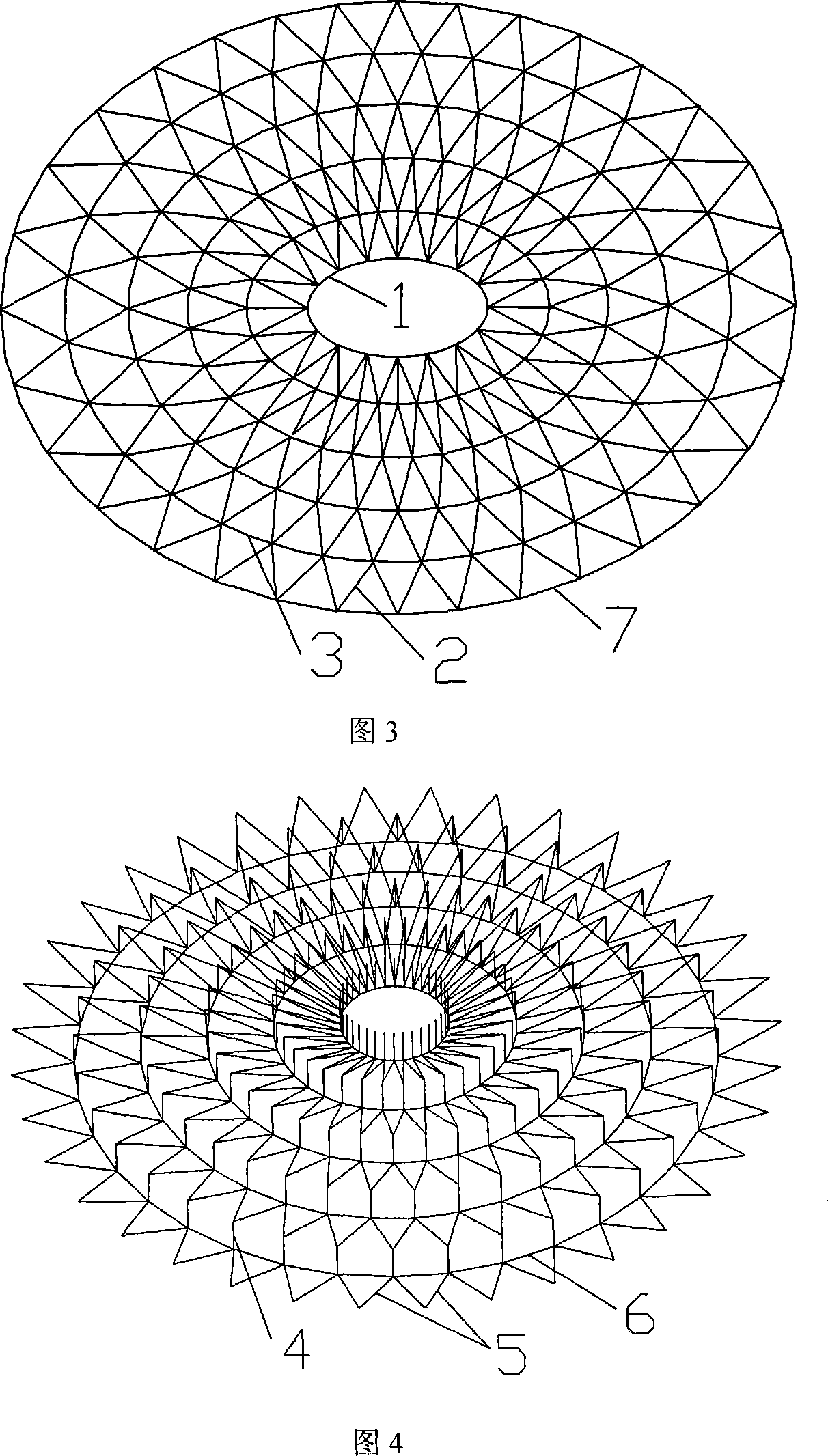

[0035] As shown in Figure 3, Figure 5, Figure 6, and Figure 8, the construction method of this embodiment is the same as that of Embodiment 1, and the only difference is that the upper central pressure ring 1, the upper radial rod 2, and the upper circumferential rod 3 The shape of the grid profile shown in Figure 3 formed with the edge member 7 is elliptical; the support system formed by the strut 4, the lower radial cable 5, and the lower circular cable 6 is selected as an elliptical shape as shown in Figure 5 .

Embodiment 3

[0037] The structure of this embodiment is the same as that of Embodiment 1, the only difference is that the outline shape of the mesh composed of the upper central pressure ring 1, upper radial rod 2, upper circumferential rod 3 and edge member 7 is polygonal.

[0038] The multi-prestressed suspensed dome structure formed by this construction method not only retains the advantages of the traditional suspensed dome structure, but also has its own unique advantages: it reduces the pressure on the upper circumferential member and even converts it into tension, reducing the It reduces its material consumption, improves the stability of components, the local stability of reticulated shells, and the overall stability of the entire structure; it makes the internal force distribution of the upper radial rods more uniform, which is conducive to the unification of component forms, and facilitates design and construction. Since the upper hoop members are not installed when the prestress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com