Whirlwind tank

A swirling pool and cone technology, applied in the direction of settlement tanks, etc., can solve the problems of increased concrete volume, increased structural weight, and increased project cost, and achieve the goal of improving the stress situation, increasing the working space, and increasing the space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

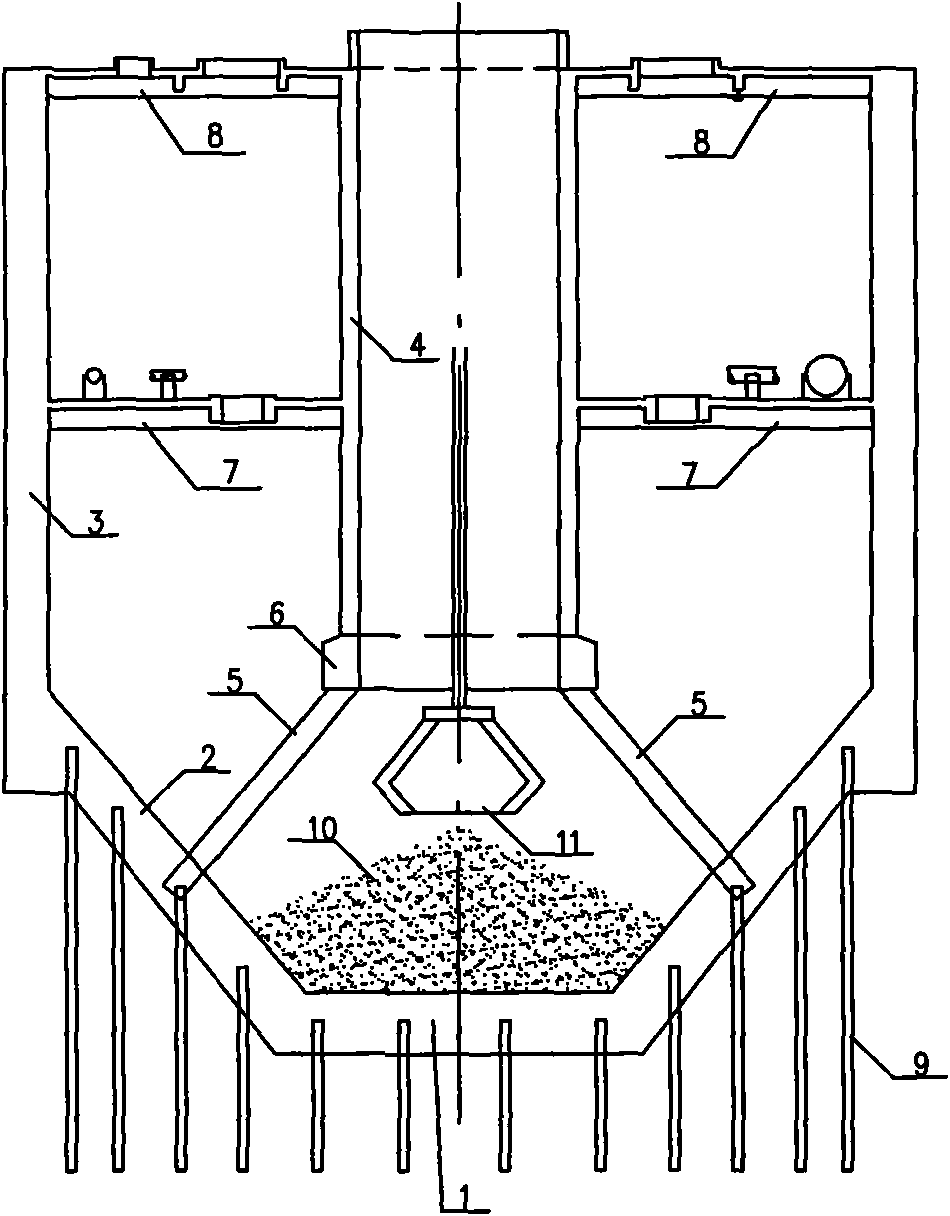

[0025] Embodiment 1: as figure 1 As shown, a swirl pool includes a bottom plate 1, an oblique cone 2, an outer cylinder 3, an inner cylinder 4, and eight oblique pillars 5 arranged in the circumferential direction; a reinforcing ring beam 6 is added to the bottom of the inner cylinder 4 The upper end of the pillar 5 is connected to the inner cylinder 4 through the reinforcing ring beam 6, and the lower end is connected to the inclined cone 2; the included angle between the inclined pillar 5 and the inner surface of the inclined cone 2 is 80°; the lower part of the inclined cone 2 and the bottom plate 1 is provided with anchor rod groups 9; the anchor rod groups 9 are manufactured by high-pressure grouting process.

[0026] When the swirl pool is working, iron slag 10 is accumulated on the bottom plate 1 and the inclined cone 2, and the grab bucket 11 grabs the iron slag in the space surrounded by the inclined pillars 5. The buoyancy is balanced by the pull-out force of the an...

Embodiment 2

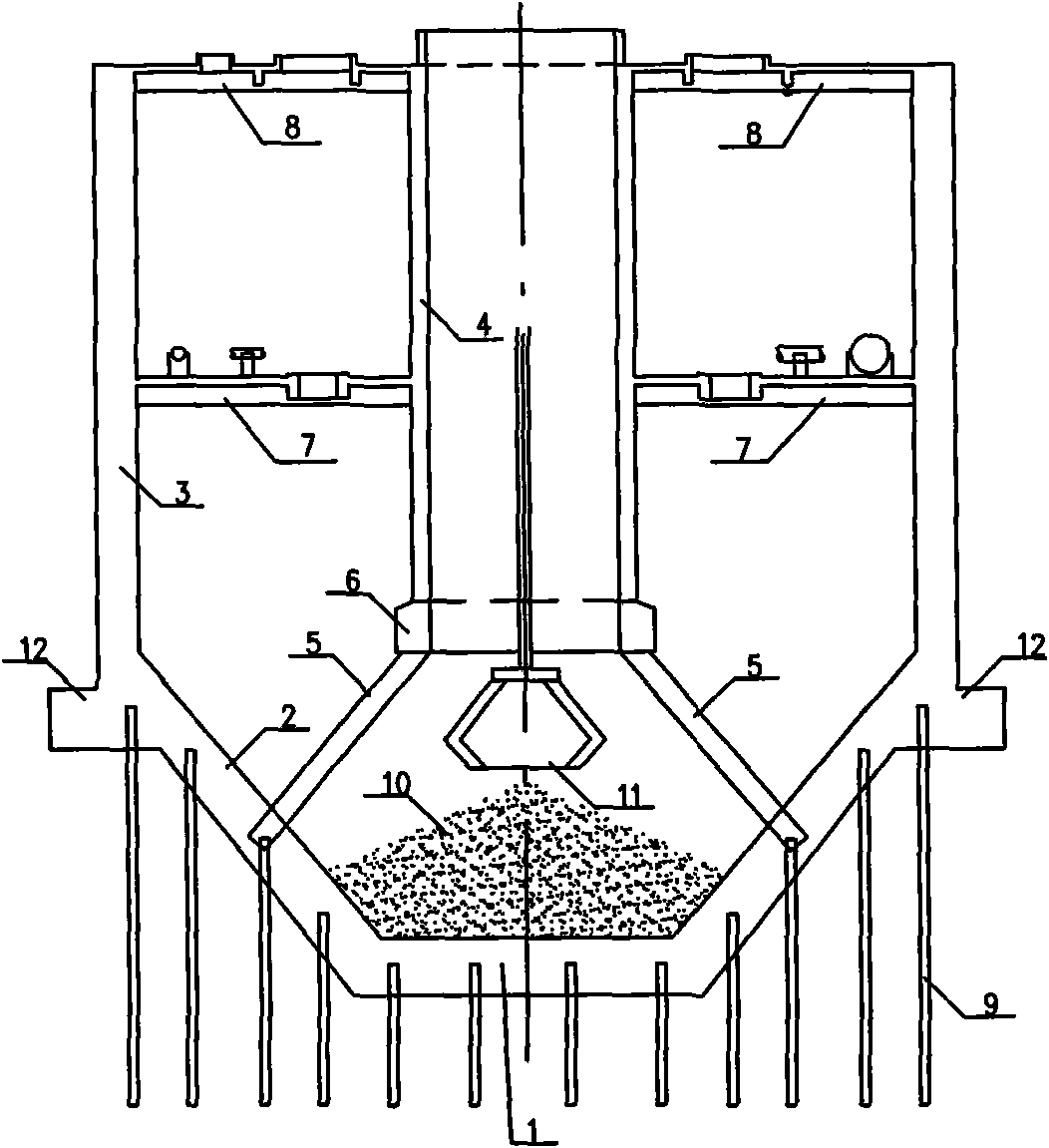

[0027] Embodiment 2: as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that an external protruding ring beam 12 is provided at the junction of the oblique cone 2 and the outer cylinder 3 . Other structures of this embodiment are the same as those of Embodiment 1. When the swirl pool of this embodiment is in operation, the earth pressure acts vertically on the lower surface of the inclined cone 2 and the bottom plate 1, and the outer hanging ring beam 12 constrains the top of the inclined cone 2, and the top of the inclined cone 2 generates an outward thrust, and the outer hanging The ring beam 12 is under tension; on the other hand, the earth pressure acts vertically on the outer surface of the outer cylinder 3, the overhanging ring beam 12 constrains the bottom of the outer cylinder 3, and the overhanging ring beam 1 is under compression, which can partially balance the top of the inclined cone 2 outward thrust. The other components of this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com