Technological method for enhancing bearing capacity of pressure-resistant structure

A technology of bearing capacity and process method, which is applied in the field of enhancing the bearing capacity of pressure-resistant structures, can solve the problems of inability to offset each other, reduce the ultimate bearing capacity of the structure, increase, etc., achieve accurate quantitative control, eliminate initial stress defects, and reduce process effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

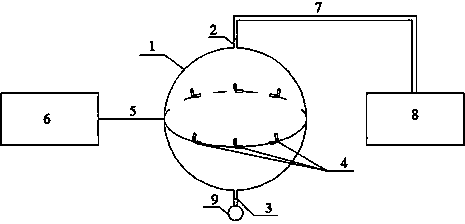

[0044] combined with figure 2 , to further describe the present invention:

[0045] Step 1: Prepare the plate, and then manufacture the pressure-resistant spherical shell 1 through conventional processes such as welding or machining. The above is the same as the prior art, and will not be repeated here;

[0046] Step 2: Open two threaded holes with a diameter of about 2 mm on the symmetrical position of the spherical shell 1, and install the upper high-pressure threaded double-way joint 2 and the lower high-pressure threaded double-way joint 3;

[0047] Step 3: With the center of the ball as the center, draw a line on the outer surface of the spherical shell, and the formed circle is perpendicular to the central axis of the threaded hole. Paste 4 to 8 groups of strain gauges 4 on the scribe line and make them evenly distributed on the circumference. Each group of strain gauges is composed of two strain gauges in the tangential direction and perpendicular to the tangential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com