Self-resetting steel frame beam-side column joint and construction method thereof

A steel frame beam, self-reset technology, applied in building components, earthquake resistance, building types, etc., can solve the problem of poor ductility and energy dissipation capacity of joint structures, large uncertainty of energy dissipation capacity and self-resetting performance of beam-column joints, etc. problems, to achieve superior superelasticity and energy dissipation capacity, improve structural ductility and energy dissipation capacity, and reduce residual deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

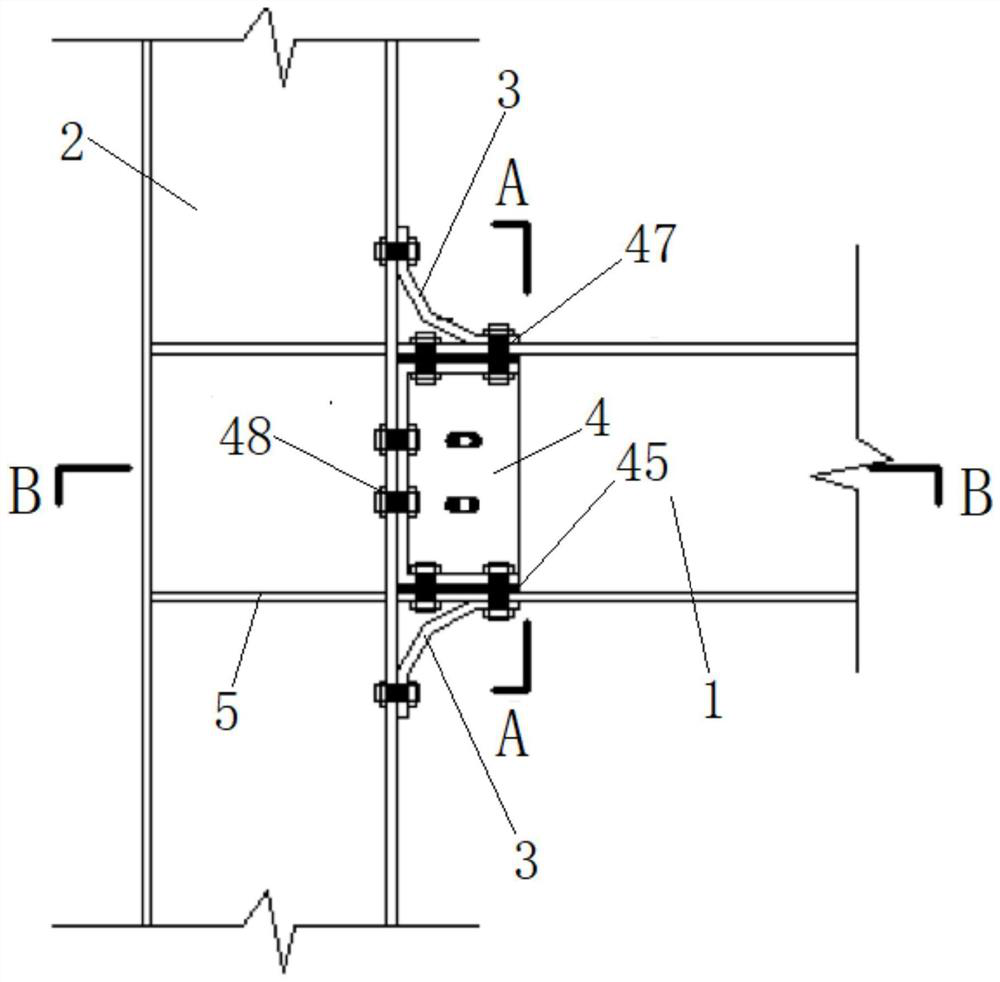

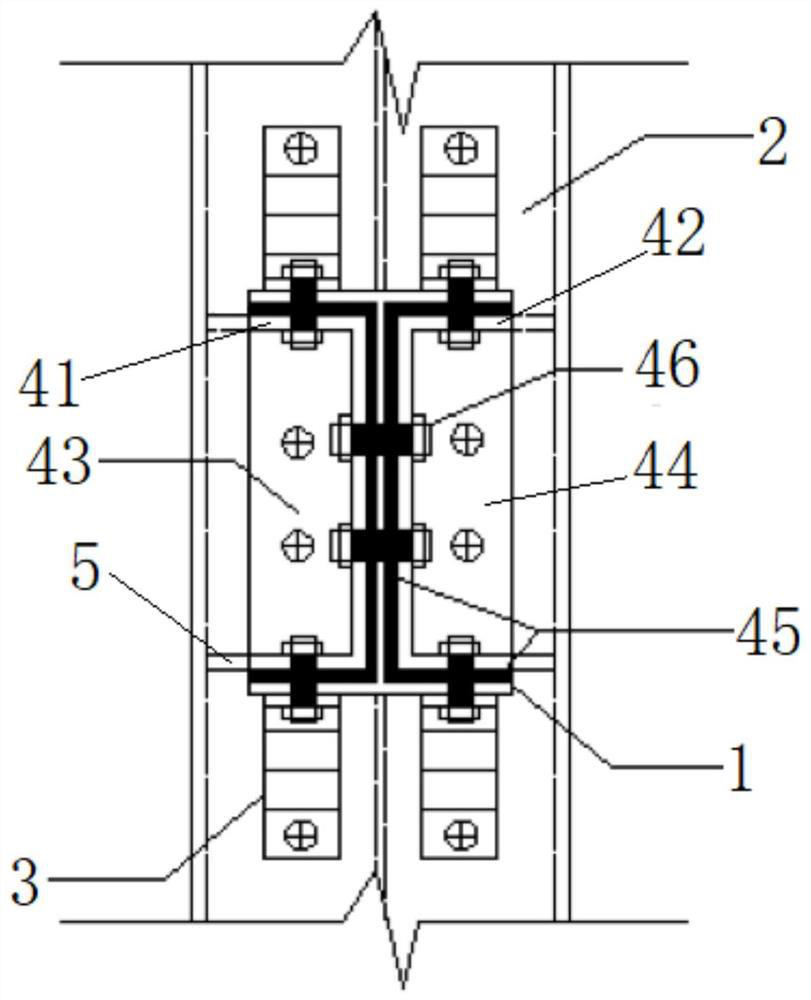

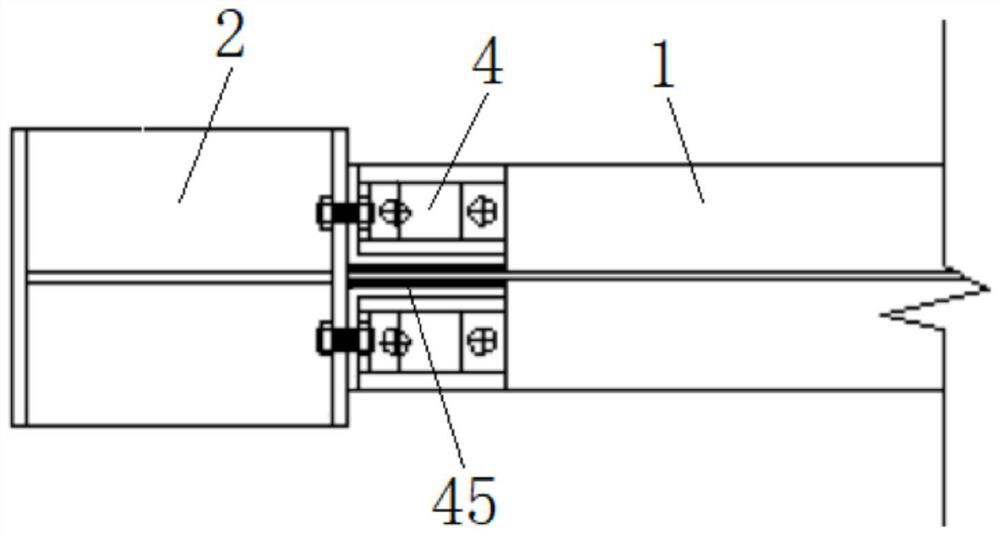

[0056]This embodiment provides a self-resetting steel frame beam-side column joint, including a steel column, a steel beam on one side of the steel column, a shape memory alloy bent steel plate connecting the flange of the steel column and the flange of the steel beam, and The frictional energy dissipator located at the web of the steel beam; the frictional energy dissipator includes an end plate connector set on the web of the steel beam and connected to the flange of the steel column, and a filling between the end plate connector and the steel beam web Energy-dissipating friction plates, high-strength bolts that pass through the web of the steel beam and connect the end plate connector, the energy-dissipating friction plate and the web of the steel beam together. The end plate connector includes connecting steel plates and channel steel fixed on the connecting steel plates , the web plate of the channel-shaped steel has oblong bolt holes; among them, the connecting steel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com