Overall pier and beam built-in connecting structure and construction method thereof

A pier-beam and integral technology, which is applied in the connection structure of integral pier-beam embedding and its construction field, can solve problems such as damage and low ultimate bearing capacity, and achieve enhanced connection strength, improved shear resistance, improved shear stiffness and The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

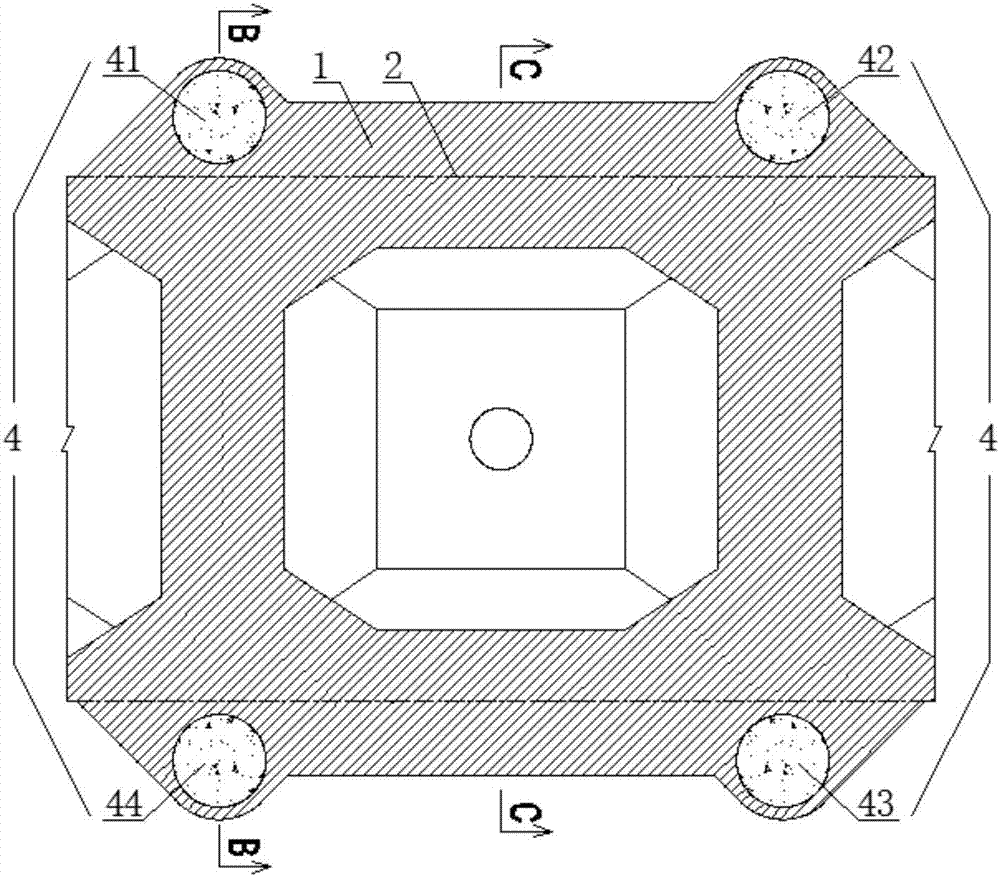

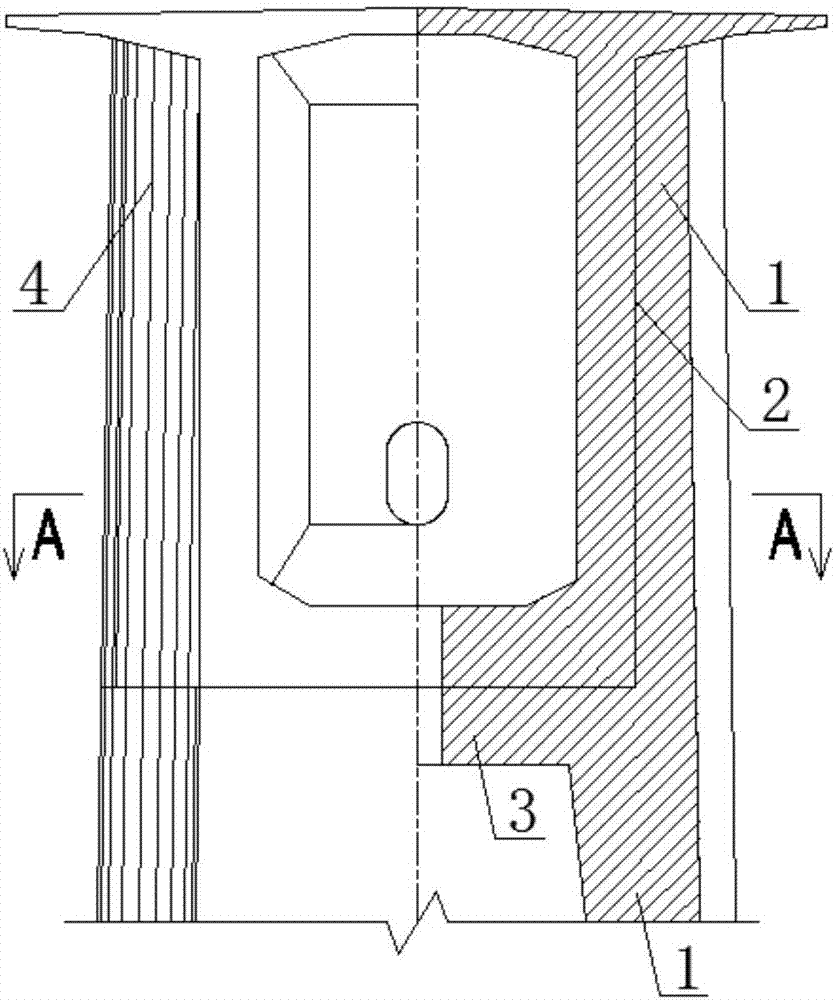

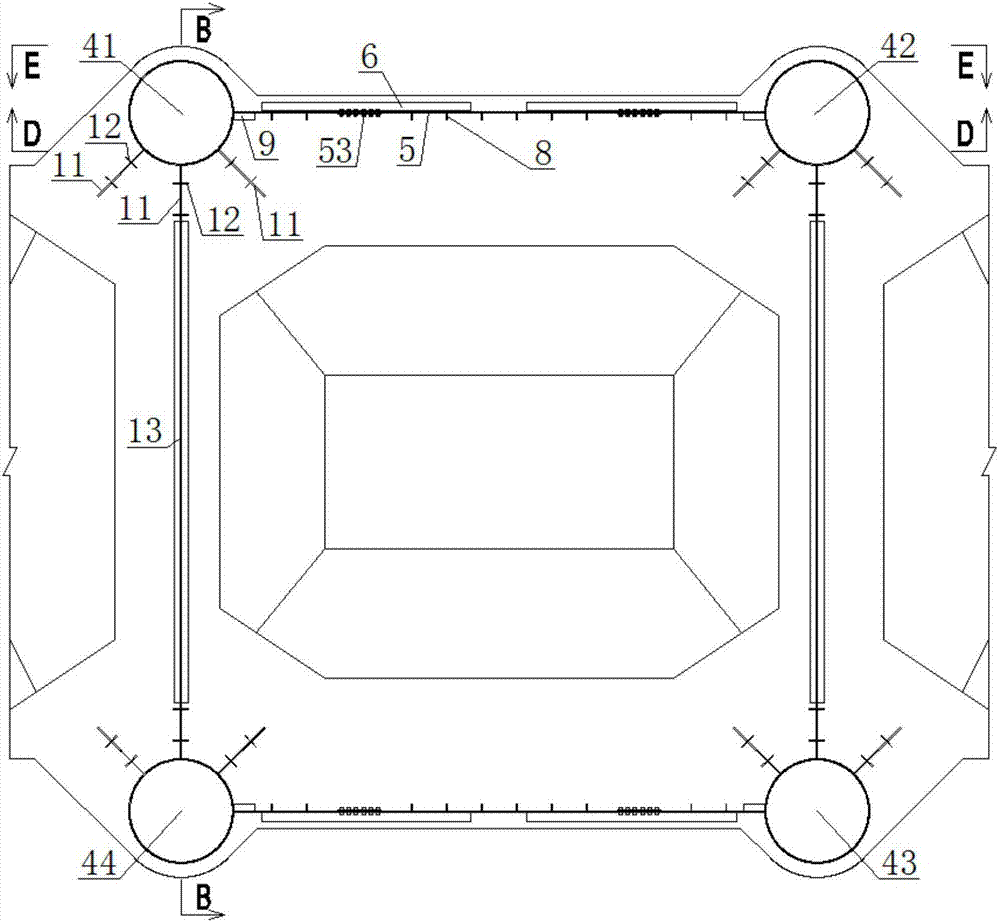

[0045] A connection structure embedded in integral piers and beams, such as figure 1 , figure 2 As shown, including pier 1 and main girder 2, pier 1 is a steel pipe concrete composite pier with steel pipe concrete as the main stress member, No. 1 main steel pipe 41, No. 2 main steel pipe 42, No. 3 main steel pipe 43 and No. 4 main steel pipe 44 The four main steel pipes 4 are respectively arranged at the four corners of the pier 1, the main girder 2 is a box girder structure, and the pier 1 is widened in the transverse direction, so that the transverse dimension of the top of the pier 1 is greater than the transverse dimension of the bottom of the main girder 2, and the The full width of the girder body of the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com