Orthogonal laminated wood-concrete composite floor and reinforcing method

A technology of combining floor slabs and concrete slabs, which can be used in floor slabs, building maintenance, building components, etc., and can solve problems such as poor stiffness and stability, and insufficient ultimate bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

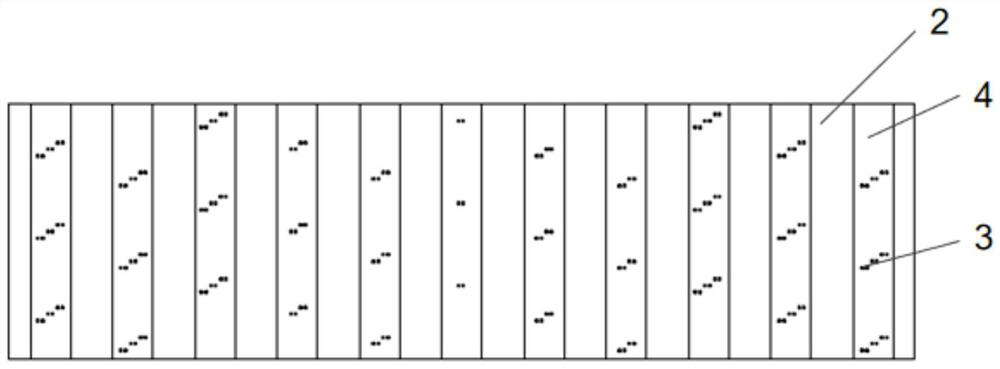

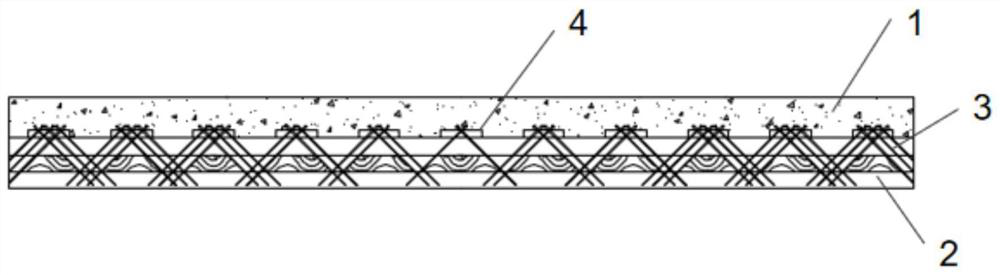

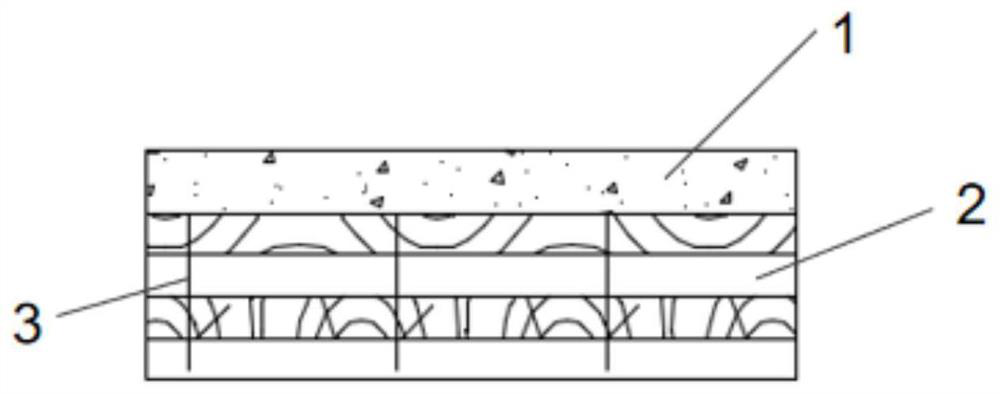

[0034] see Figure 1 to Figure 5 As shown, this embodiment provides a cross-glued timber-concrete composite floor, including a concrete slab 1, a CLT slab 2, several pneumatic nails 3 and several wooden pads 4;

[0035] The CLT plate 2 includes opposing first and second surfaces, see figure 2 As shown, the CLT board 2 is formed by lamination of multi-layer wood boards, and several wooden spacers 4 are arranged on the first surface of the CLT board 2. In this embodiment, several wooden spacers 4 are arranged along the length of the CLT board 2. The directions are equidistantly arranged in parallel on the first surface of the CLT board 2, and the wooden spacer 4 and the CLT board 2 are glued by one-component polyurethane;

[0036] In this example, see Figure 4 Shown, wooden spacer 4 is strip shape, and the length of wooden spacer 4 is consistent with the width of CLT plate 2, and the width of the CLT plate 2 that present embodiment provides is 310mm, so in the present embodi...

Embodiment 2

[0044] Based on the same inventive concept, this embodiment also provides a method for reinforcing a cross-glued wood-concrete composite floor, comprising the following steps:

[0045] A CLT board is provided, the CLT board includes opposite first surfaces and second surfaces, and the CLT board is formed by lamination of multi-layer wood boards;

[0046] On the first surface of the CLT, a number of wooden pads are arranged in parallel at equal intervals along the length direction, and the wooden pads and the CLT board are glued by one-component polyurethane;

[0047] A number of pneumatic nail strips are nailed into the upper surface of the wooden block, and the pneumatic nail strip penetrates the wooden spacer and is inserted into the CLT board. In this embodiment, the far end of the pneumatic nail strip is inserted into 4 / 5 of the bottom sawn wood of the CLT board At the thickness, there is an included angle between the insertion direction of the pneumatic nail strip and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com