Duplex I-shaped energy dissipation device and supporting structure thereof

A technology of energy-dissipating devices and supporting structures, which is applied in the direction of building components, building types, building structures, etc., can solve the problems of low yield point steel plate cost, expensive energy-dissipating device accessories, and large impact on energy-dissipating device performance. Achieve the effect of simple and reasonable structure arrangement, convenient and quick installation, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

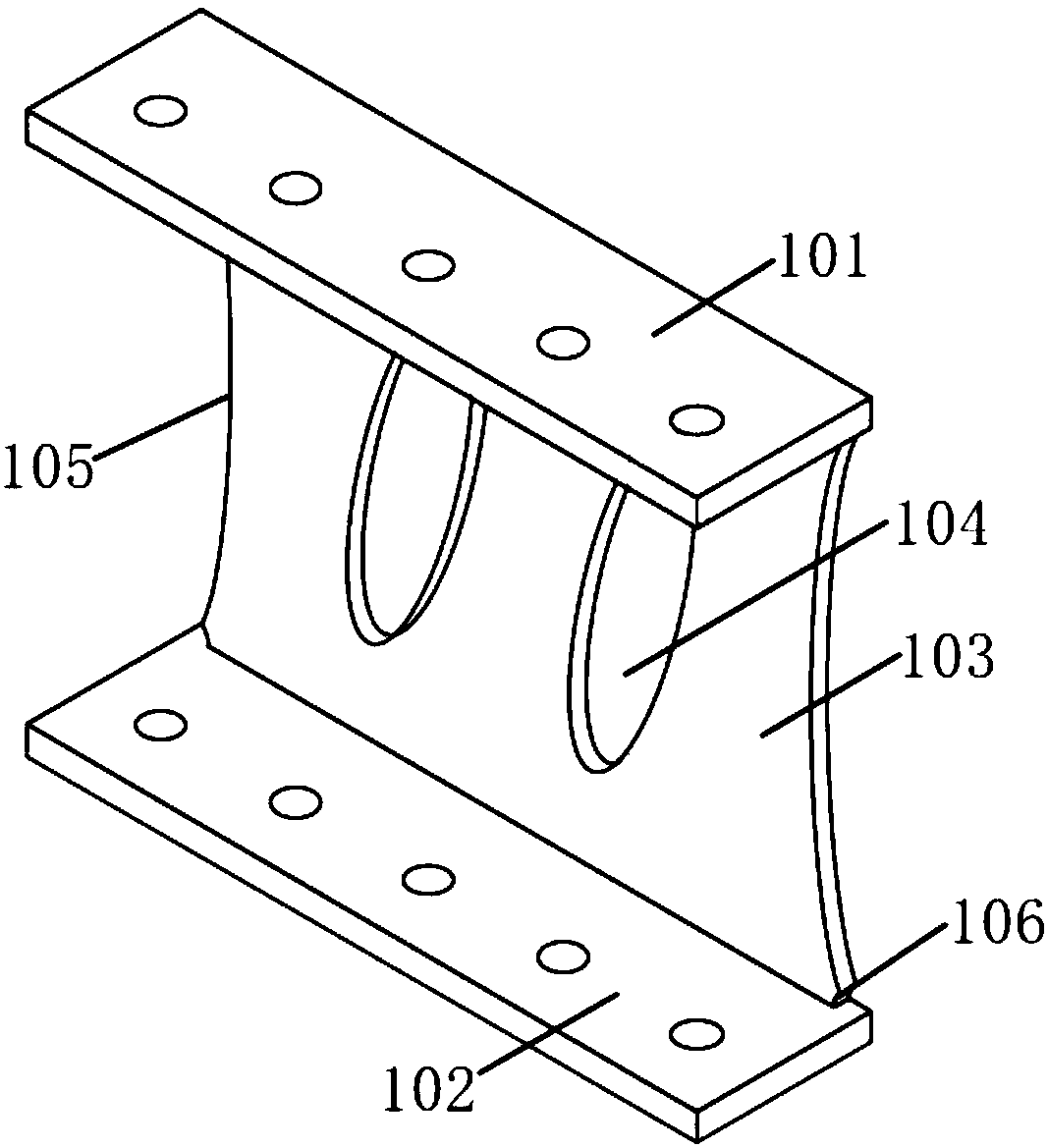

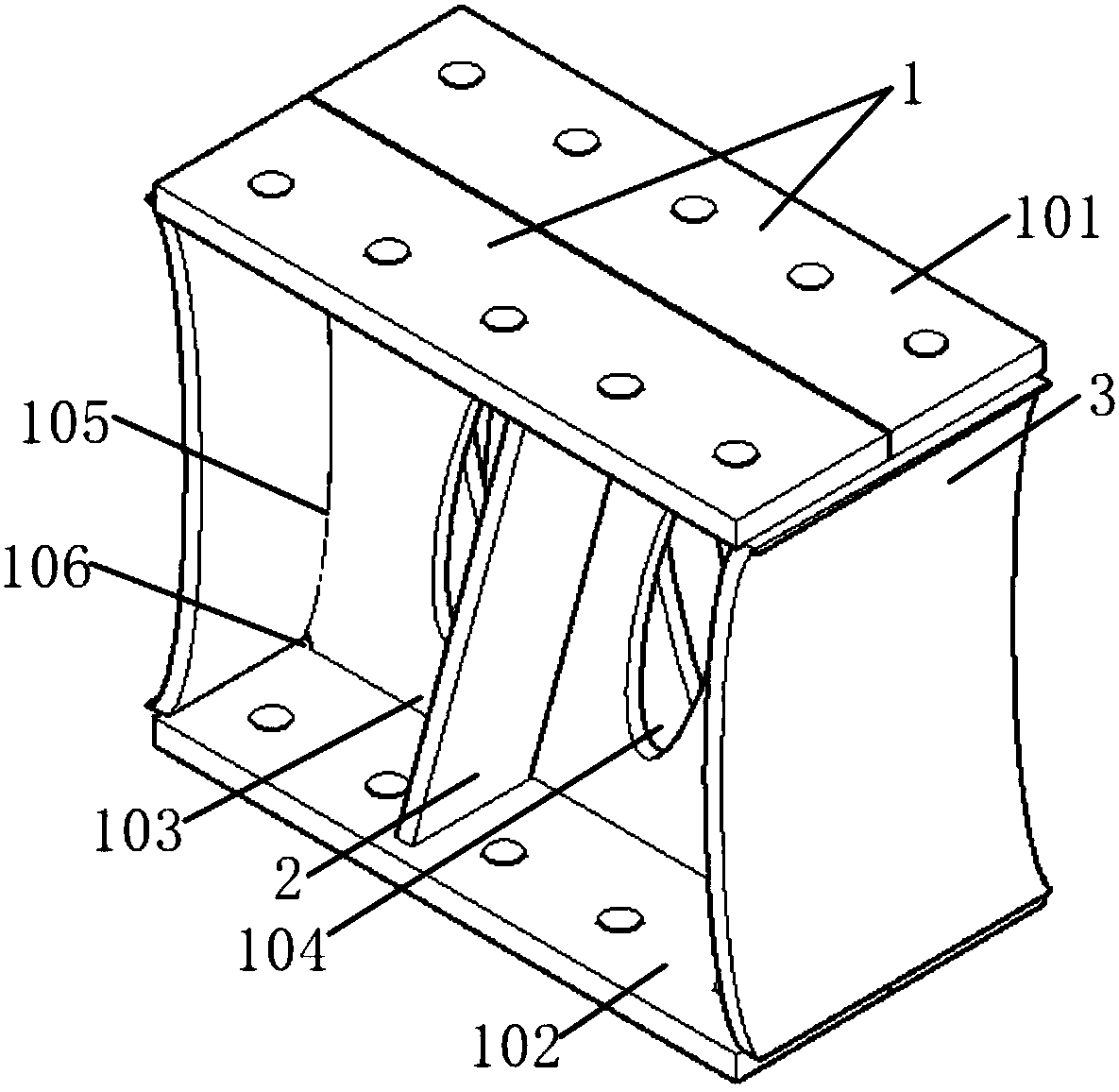

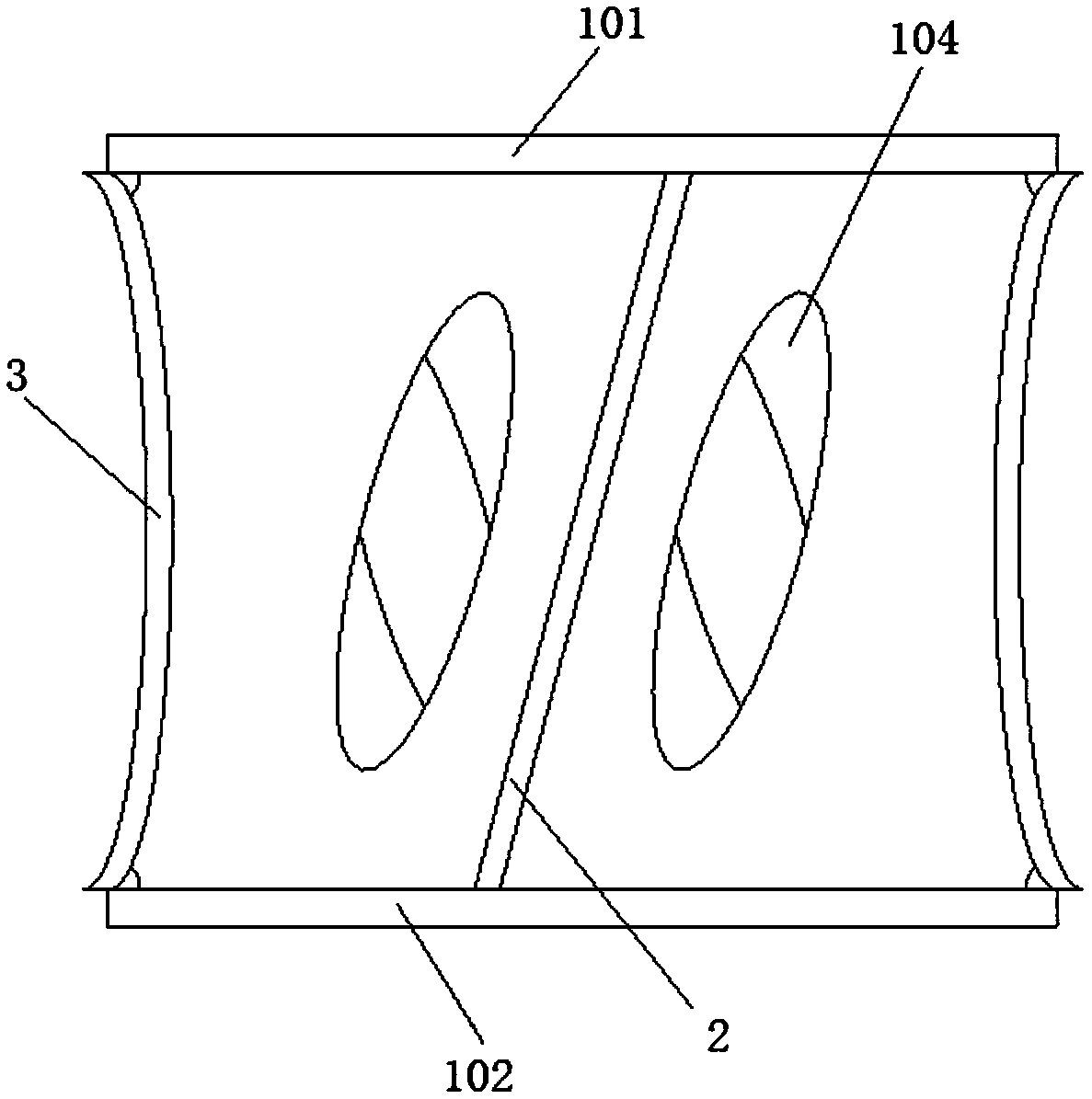

[0046] like figure 1 and 2 As shown, the present invention discloses a double-combined I-shaped energy dissipation device, which includes two energy dissipation panels 1 , a stiffening panel 2 and an arc-shaped sealing panel 3 arranged at intervals with their backs facing each other. The stiffening plate 2 and the arc-shaped sealing plate 3 are also preferably Q235 steel plates. Wherein the energy dissipation plate 1 is a U-shaped plate integrally formed by the upper wing plate 101, the lower wing plate 102 and the web 103, and the parallelism error of the inner and outer surfaces of the upper wing plate 101 and the lower wing plate 102 is less than 0.5mm; Energy plate 1 can be made by cutting hot-rolled Q235H section steel along one side of the web to remove redundant wings, among which ultra-high pressure water jet cutting or wire cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com