Offshore steel pipe distributed post-grouting device, air-type grouting assembly and construction method

A technology of grouting components and steel pipe piles, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problem that the pile-soil system cannot be formed effectively, the grout that is pressed in cannot cover the entire range of the pile body, and the foundation Pile settlement reduces costs and other issues, achieving the effect of bonding and load transfer, reducing foundation pile settlement, and improving bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

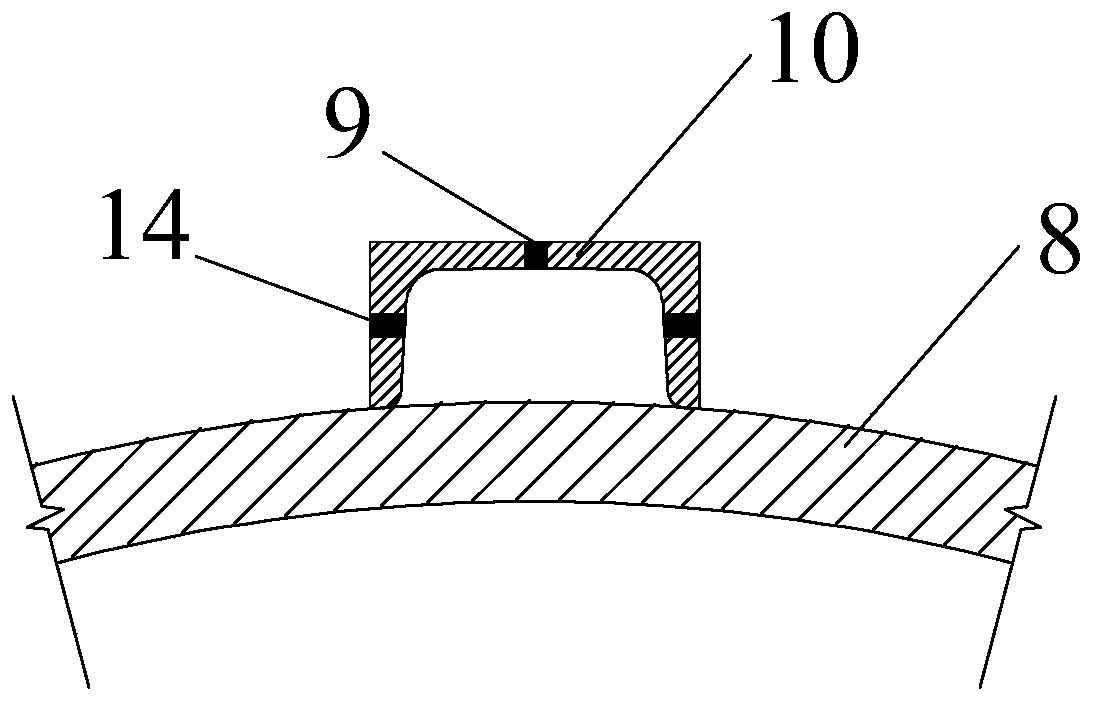

[0041] Such as Figure 5 As shown, a pneumatic grouting assembly of the present invention includes a grouting pipe 1, a square rubber air bag 2, an upper air pipe 3, a lower air pipe 4, a slurry outlet 5, an upper fixing clip 6 and a lower fixing clip 7. Two square rubber airbags 2 are covered on the outside of the grouting pipe 1 at intervals up and down. The upper and lower ends of the square rubber airbag 2 at the upper end are fixed and clamped on the grouting pipe 1 by the upper fixing clip 6, which is located at the lower end. The upper and lower ends of the square rubber airbag 2 fix and clamp the square rubber airbag 2 on the grouting pipe 1 through the lower fixing clip 7 .

[0042]The upper air pipe 3 is connected with the square rubber air bag 2 at the upper end to inflate the square rubber air bag 2, and the lower air pipe 4 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com