Oriented fixed-layer slurry-injecting sleeve valve tube and slurry-injecting method

A technology of sleeve valve pipe and grouting, which is applied in the field of geotechnical engineering grouting, can solve the problems of increasing geological environmental pollution, failure of grouting reinforcement, and increasing construction difficulty, so as to reduce unnecessary pollution, have strong practicability, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

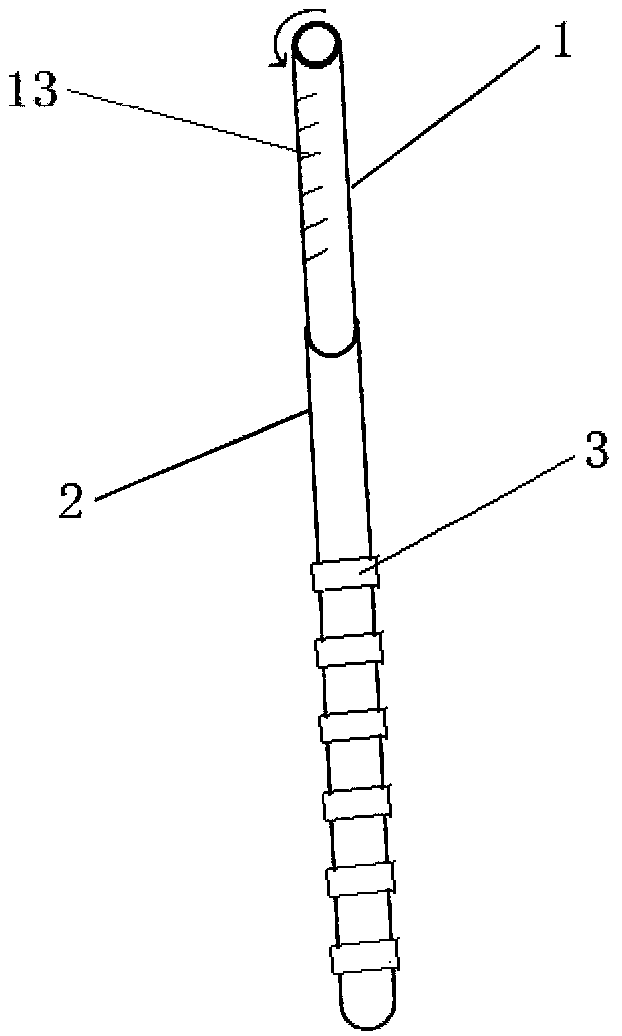

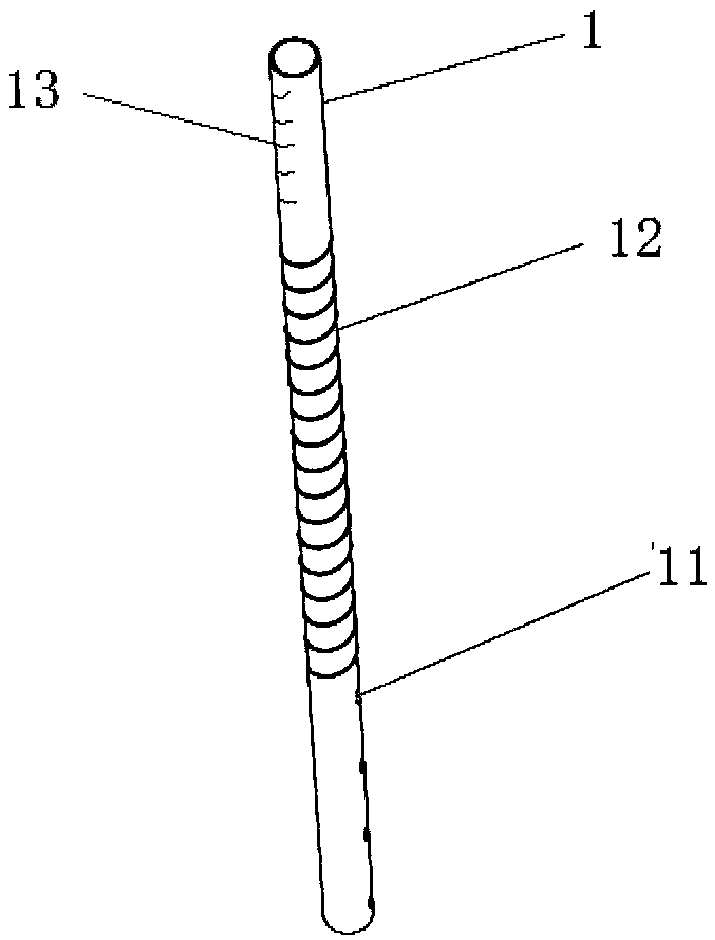

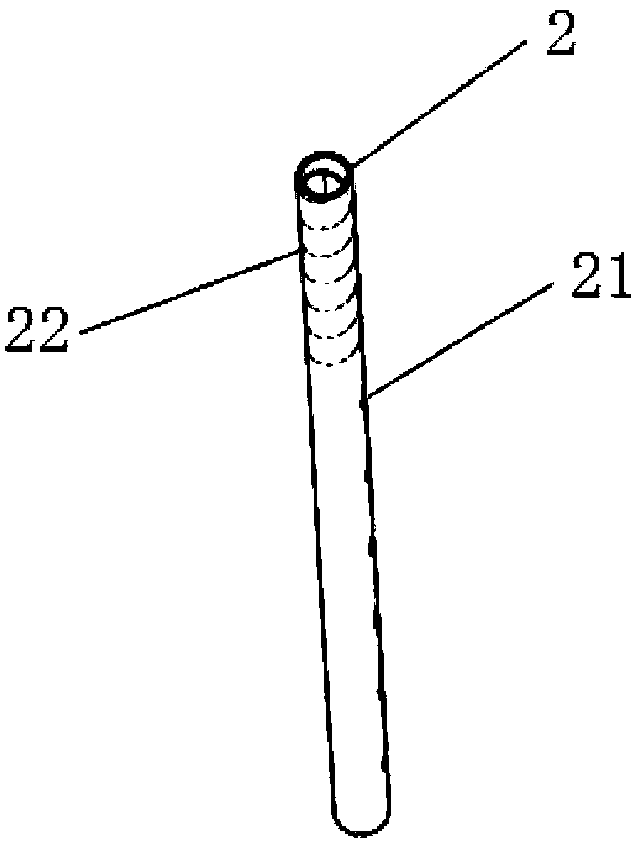

[0020] Such as Figures 1 to 3 As shown, a directional and layered grouting sleeve valve tube of the present invention includes an inner tube 1 , an outer tube 2 and a plurality of rubber rings 3 . A number of slurry outlet holes 21 with the same diameter are arranged at equal intervals from bottom to top on one side of the outer tube 2 , and an internal thread 22 is provided above the topmost slurry outlet hole 21 of the outer tube 2 . The inner pipe 1 is embedded in the outer pipe 2, and a plurality of grouting holes 11 with the same aperture are arranged at equal intervals on one side of its lower end, and above the topmost grouting hole 11 of the inner pipe 1, there is a groove corresponding to the inner thread 22. With the matched external thread 12, the bottom end face of the inner pipe 1 is closed. The rubber ring 3 is sleeved on the outer tube 2 and sealed on the pulp outlet 21 , and a small hole is opened on the rubber ring 3 corresponding to the pulp outlet 21 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com