Variable-diameter steel tube built pile capable of reducing negative friction

A technology of negative friction resistance and steel pipe piles, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problems of reducing negative friction resistance, achieve the effect of reducing negative friction resistance, save material use, and have good horizontal bearing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

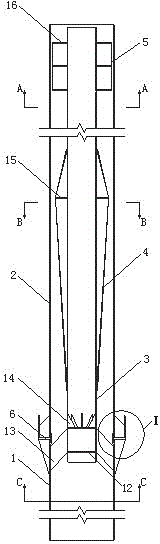

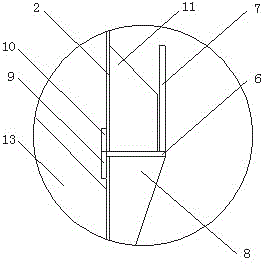

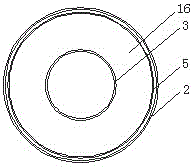

[0028] Accompanying drawing is only a specific embodiment of the present invention, figure 1 It is a schematic diagram of the longitudinal section structure of the present invention. It can be seen from the figure that the present invention includes a large-diameter steel pipe pile 1 and a piling casing 2, and a small-diameter steel pipe pile 3 is arranged in the piling casing 2, and the small-diameter steel pipe pile 3 A variable diameter casing 4 is arranged around, and an enlarged top cylinder 5 is arranged around the upper part of the small diameter steel pipe pile 3 . In the present invention, after the vertical ground is knocked into the foundation, the piling casing 2 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com