Supporting and protecting composite anti-slide pile suitable for high-attitude and high-intensity regions

A technology of high-altitude, anti-slide piles, applied in sheet pile walls, excavation, construction, etc., to achieve the effects of increased tensile capacity, good bonding performance, and enhanced plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

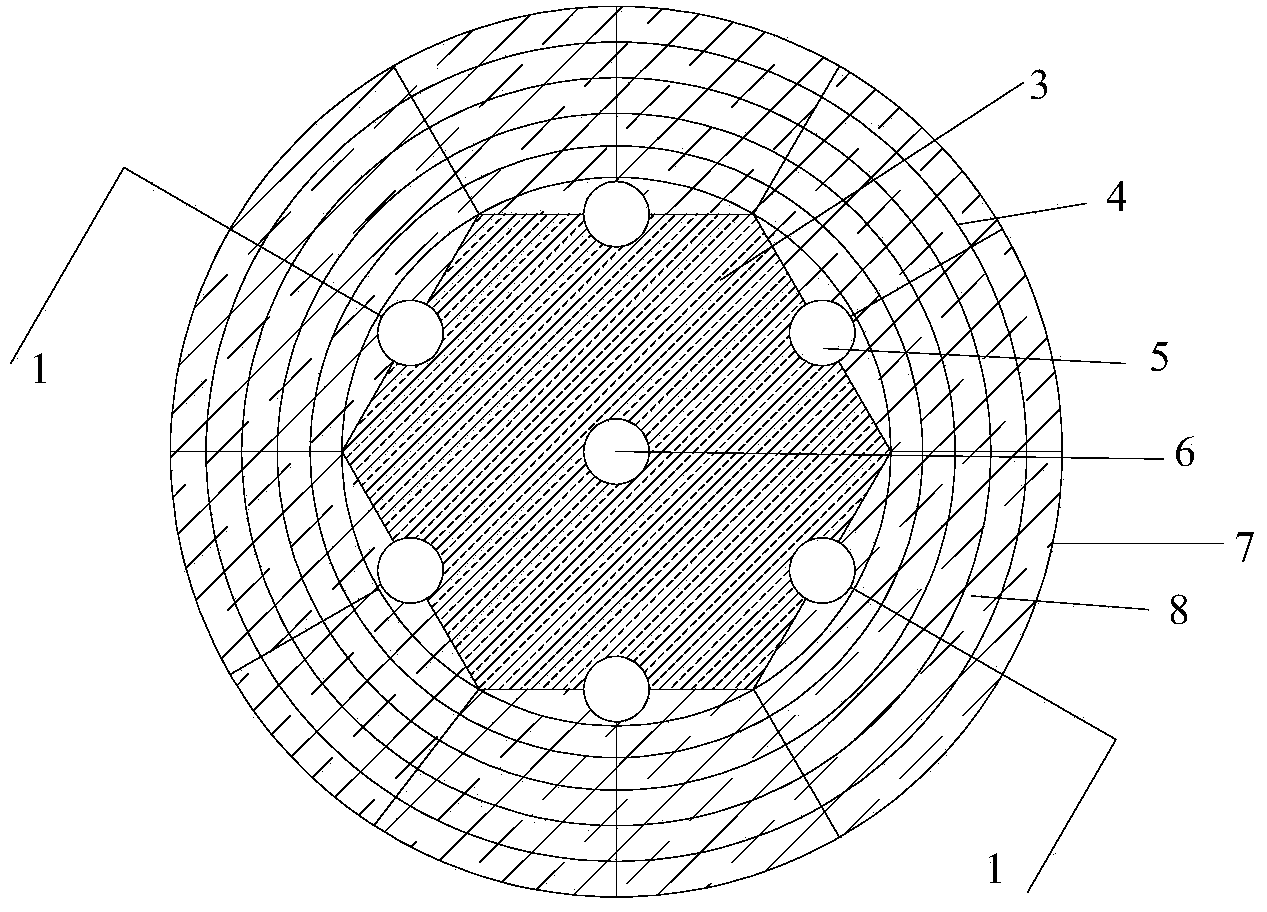

[0020] This embodiment is to install composite anti-slide piles on high slopes. According to geological and terrain conditions, the design diameter of the composite anti-slide pile is 1500mm, and the diameter of the circumscribed circle of the pile core is 800mm.

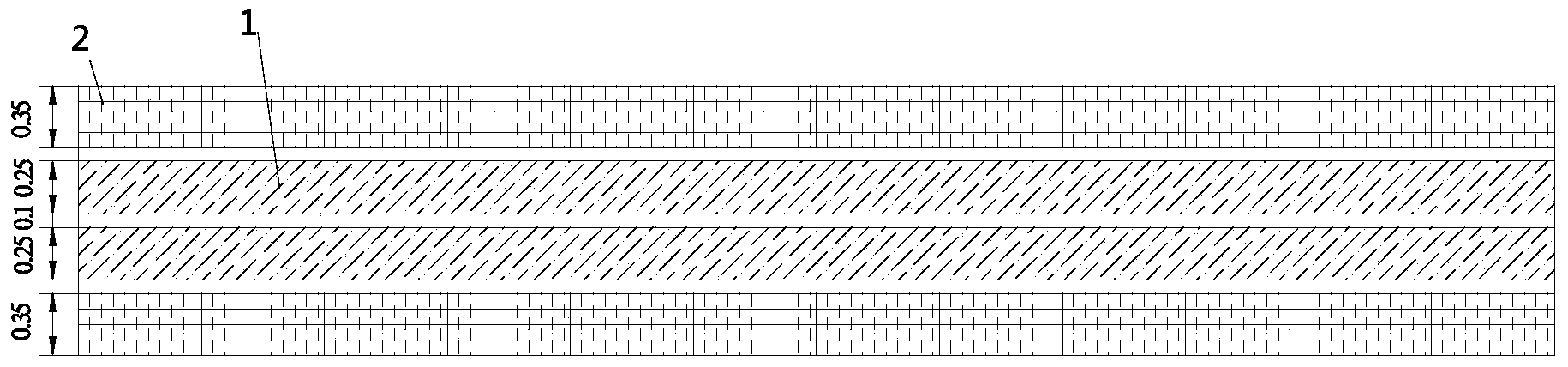

[0021] (1) Make the pile core. According to the pile hole diameter and geological and topographic conditions, the side length of the regular hexagonal prefabricated prestressed pile is designed to be 800m, and a groove is evenly distributed along the axis on each surface. The groove is semicircular, its diameter is 80-110mm, and the diameter of the grouting pipe is 110mm.

[0022] Prefabricated prestressed piles are produced by centrifugal forming technology and high temperature and high pressure steam curing. Select high-strength concrete and steel bars with D-grade tou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com