Test cable and test pipe column

A technology for testing pipes and cable cores, which is applied in the directions of measurement, wellbore/well components, connections where permanent deformation plays a role, etc., and can solve the problem of low bearing capacity of test pipe strings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

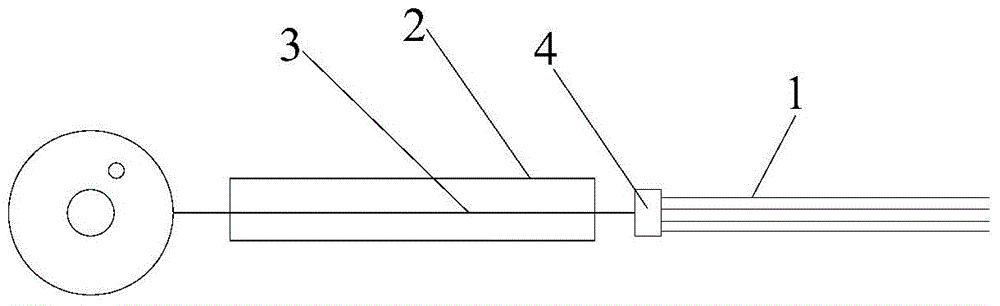

[0031] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

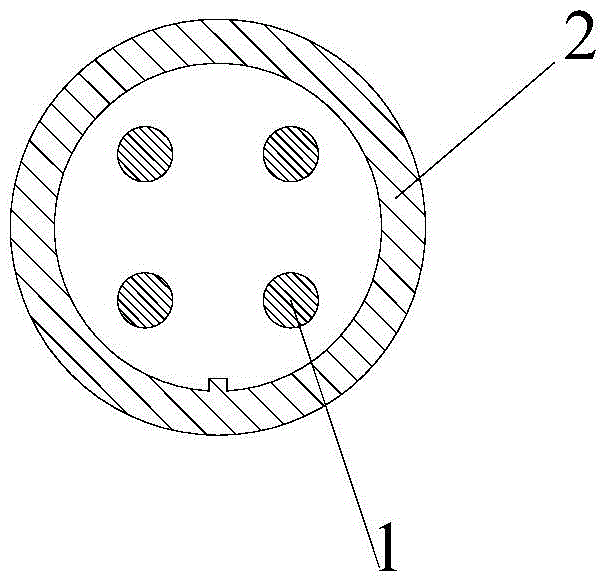

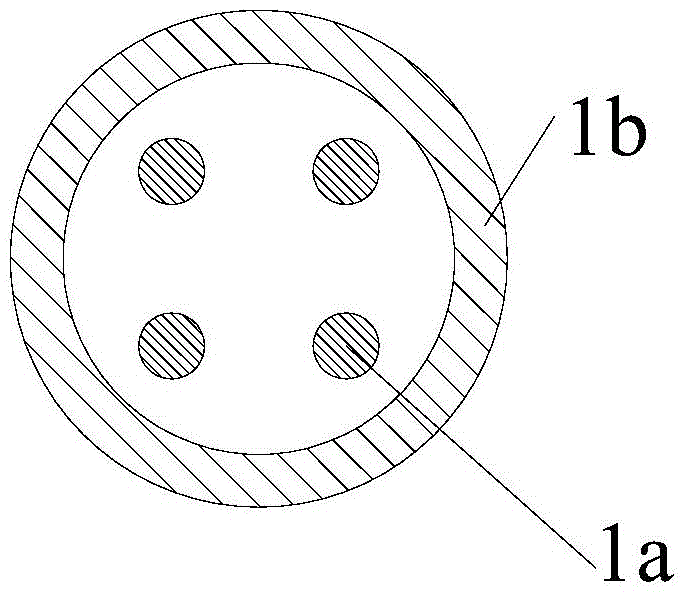

[0032] Such as Figures 5 to 10 As shown, according to the embodiment of the present invention, the test cable includes a test cable capillary 11 , a test cable core 12 and a connecting wire 13 .

[0033] Wherein, the test cable capillary 11 has a receiving through hole 111 penetrating through the test cable capillary 11 in the axial direction. The test cable capillary 11 is used to accommodate the test cable core 12 . The test cable core 12 is arranged in the receiving through hole 111 of the test cable capillary 11, and the first end of the test cable core 12 is located between the first end of the test cable capillary 11 and the second end of the test cable capillary 11, and the test cable Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com