Mechanical finishing method for wool fabric

A kind of fabric and mechanical technology, applied in the direction of fabric surface trimming, fabric kneading/softening treatment, textile and paper making, etc., can solve the problems of rough hand feeling, easy shedding, poor elongation, etc., to improve anti-pilling performance, Good air permeability, tightly locked effect between fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

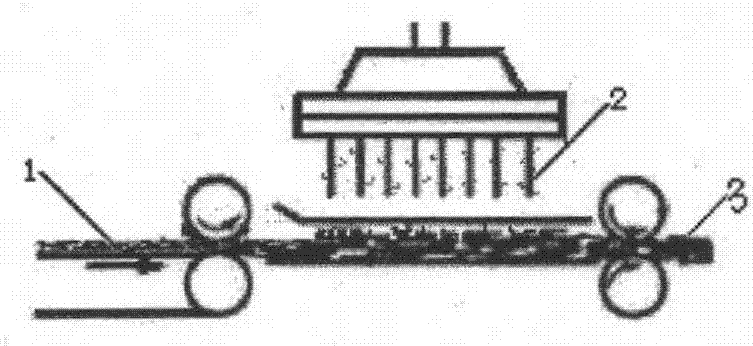

[0030] A kind of mechanical finishing method of woolen fabric:

[0031] Select 46Nm / l primary color 45 / 55 wool polyester yarn to weave on the circular knitting machine of 24G 30 ":

[0032] (1) In order to make the fabric bonded more closely and have a wool feeling after acupuncture finishing, choose 46Nm / l primary color 45 / 55 wool polyester yarn;

[0033] (2) 24G 30″ circular knitting machine is used for weaving. In order to make the fabric softer, the length of the loop is appropriately increased to 1.2mm, and weaving is carried out with flat needles;

[0034] (3) After the gray cloth is off the machine, it is boiled to remove impurities. The temperature of the boiled cloth can be controlled at about 50°C, and then rinsed with water at room temperature, then water is added at a bath ratio of 1:10-1:20, and then 1.5%- 4% (o.w.f) of silicone softener and 0.5%-2% (o.w.f) of antistatic agent, after 10-20 minutes of treatment, dehydration and drying;

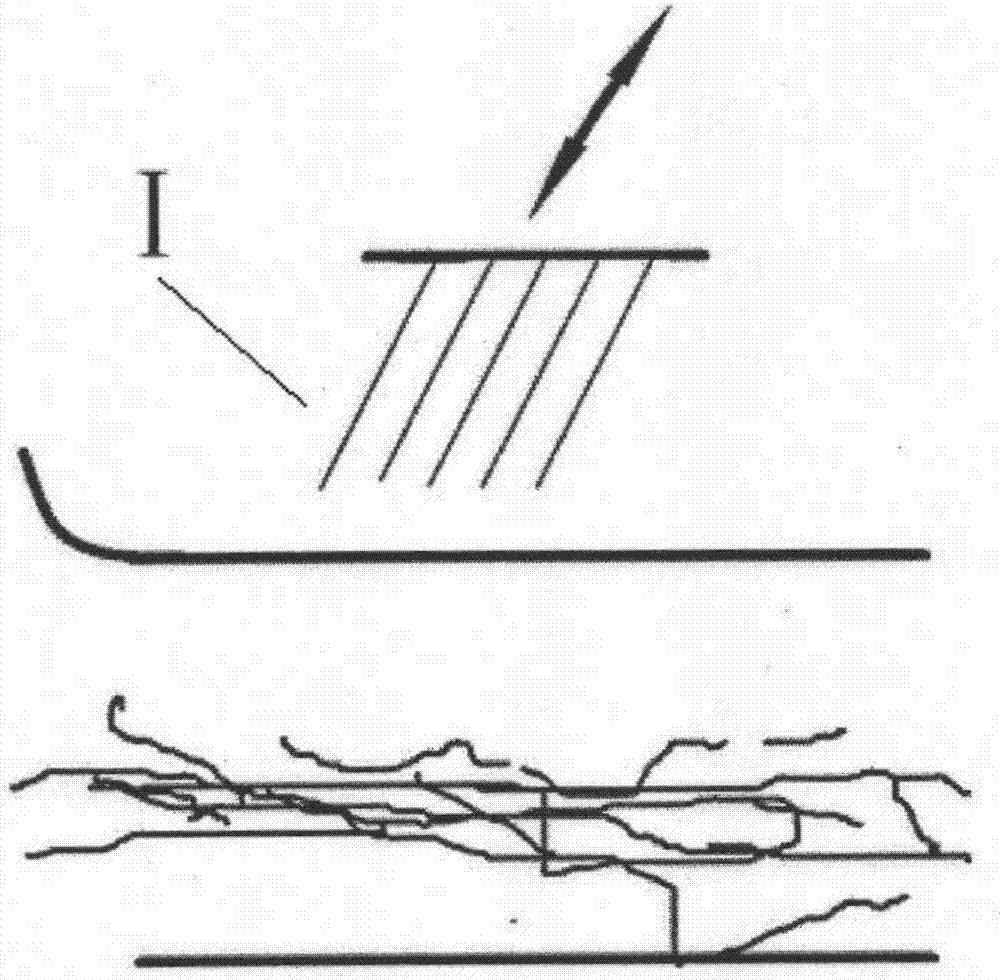

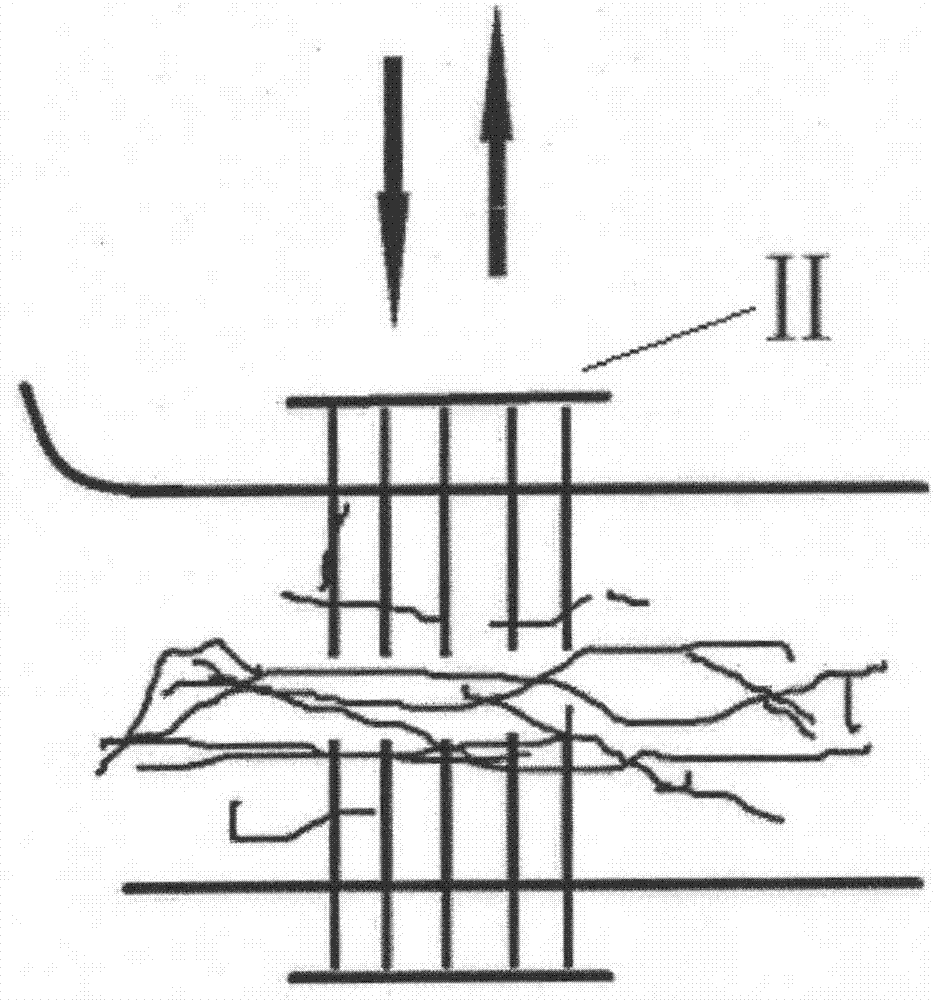

[0035] (4) Acupuncture fi...

Embodiment 2

[0038] Select 32Nm / l navy blue 30 / 70 wool acrylic yarn, 46Nm / l royal blue 50 / 50 wool acrylic yarn to weave on the circular knitting machine of 22G 30 ":

[0039] (1) select 32Nm / l dark blue 30 / 70 wool acrylic yarn, 46Nm / l royal blue 50 / 50 wool acrylic yarn to arrange in a mode of one by one, and weave on the circular knitting machine of 22G 30 ";

[0040] (2) In order to make the fabric softer, the length of the coil is appropriately increased to 1.2mm, and the beaded weave is used for weaving;

[0041] (3) After the gray cloth is off the machine, it is boiled to remove impurities. The temperature of the boiled cloth can be controlled at about 60°C, and then rinsed with water at room temperature, then water is added at a bath ratio of 1:10-1:20, and then 2%- 4% (o.w.f) of silicone softener and 0.5%-2% (o.w.f) of antistatic agent, after 10-20 minutes of treatment, dehydration and drying;

[0042] (4) Acupuncture finishing is performed on the fabric after soft finishing; three ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com