Horizontal bearing reinforcing body of soft foundation cast-in-place pile and construction method thereof

A technology of soft soil foundation and construction method, which is applied in the direction of foundation structure engineering, sheet pile wall, construction, etc., can solve the problems of difficult to guarantee the quality of piles and complicated construction operations, and achieve the improvement of horizontal bearing capacity, simple installation method and enhanced The effect of vertical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

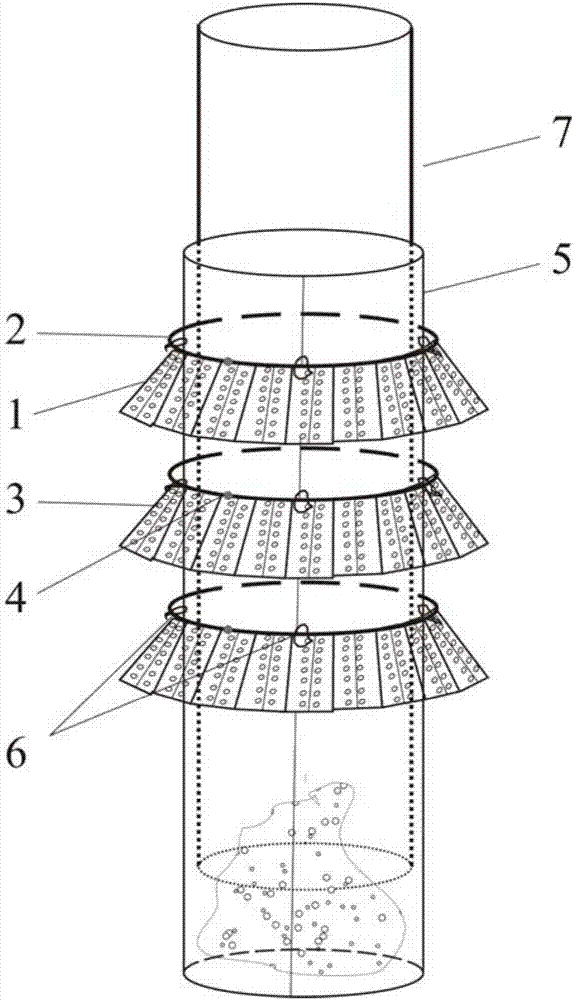

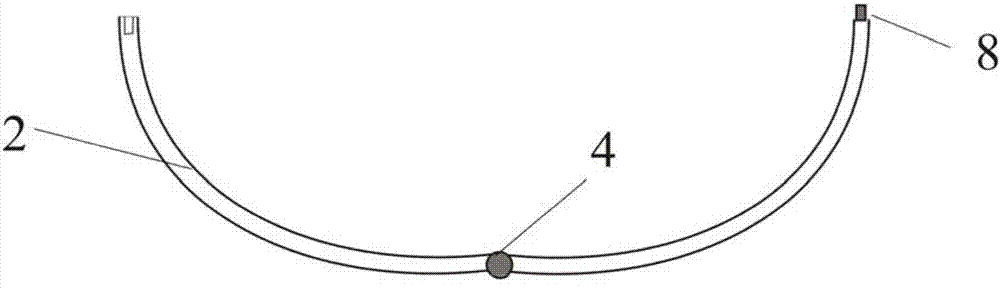

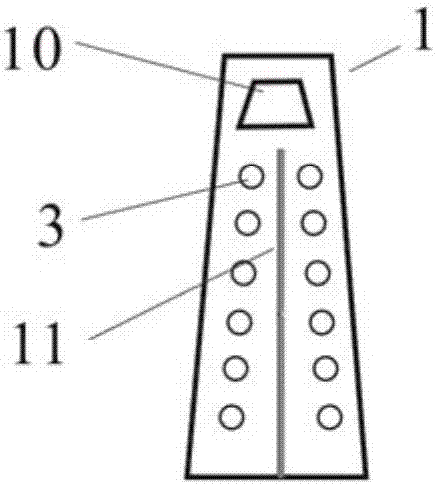

[0028] Such as figure 1 Shown is a horizontal load-bearing reinforcement of cast-in-place piles on soft soil foundations, including a set of flanges 1 and a hoop 2 with the same structure and size. The flanges 1 are evenly arranged around the hoop 2, and the flanges 1 Small holes 3 are provided; the wing plate 1 is a trapezoid with rounded corners, the short side of the wing plate 1 is provided with a slot 10, and the hoop 2 is evenly provided with protruding teeth 9 in the same number as the wing plate 1 along the circumference. The hinge between the plate 1 and the hoop 2 is realized through the gap fit between the slot 10 and the protruding teeth 9; when no external force is applied, the wing plate 1 hangs down freely, and the wing plate 5 can achieve a 90° range relative to the hoop 2. Rotation, that is: the upper surface of the wing plate 1 is subjected to downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com