Prefabricated piles, connecting structure of prefabricated piles and construction method of connecting structure

A technology for connecting structures and prefabricated piles, which is used in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of carbon fiber materials that cannot be welded and extruded, and the connection form cannot be applied, and achieves reliable connection, convenient installation, and resistance to resistance. The effect of high level and pull-out bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

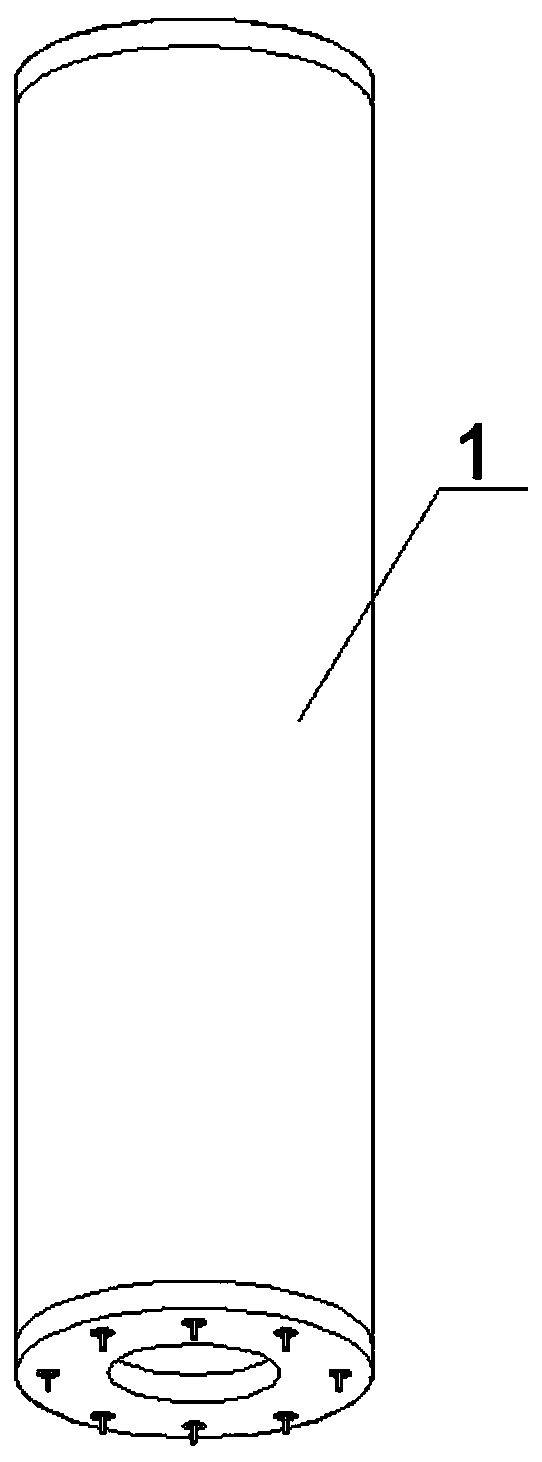

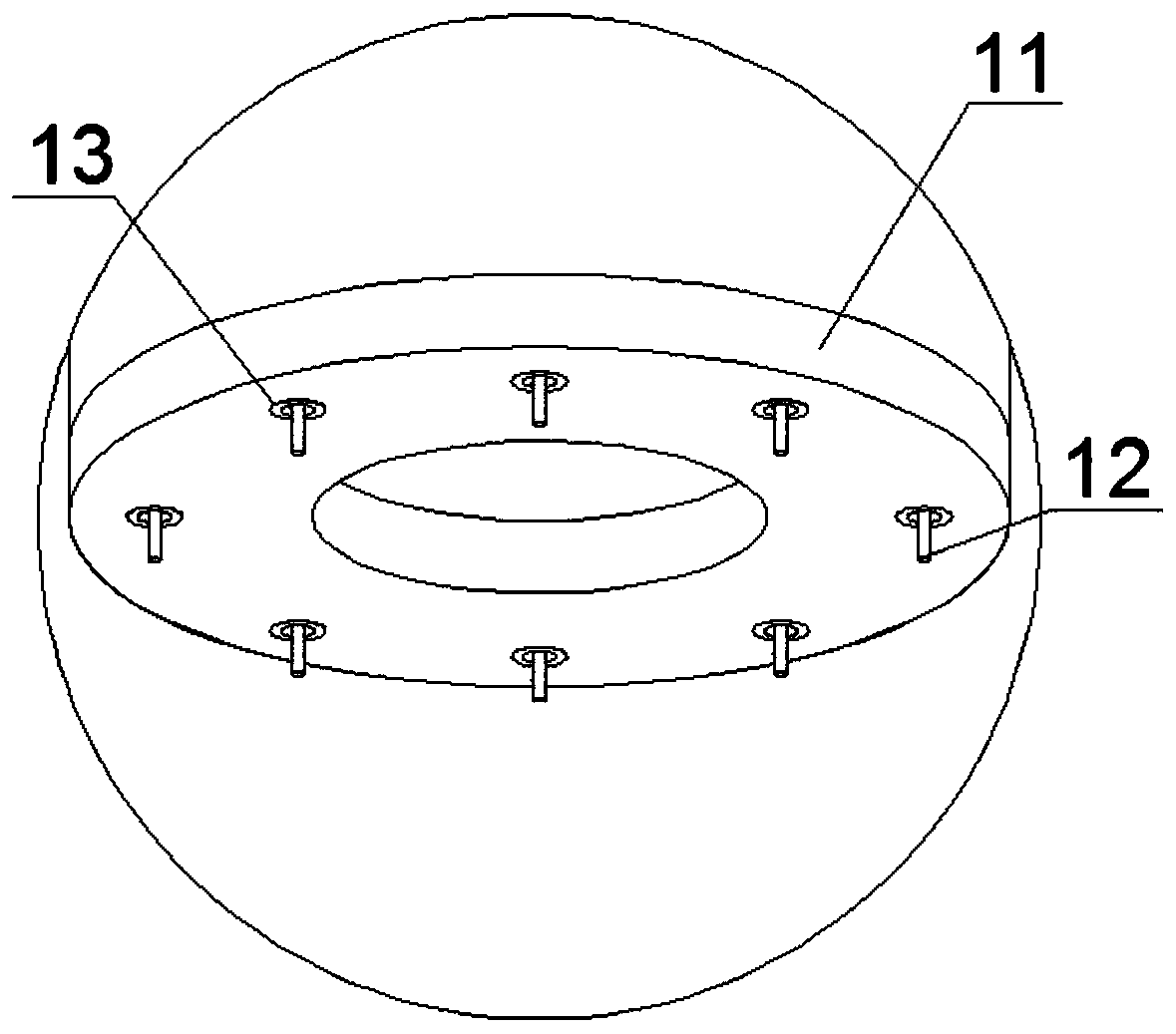

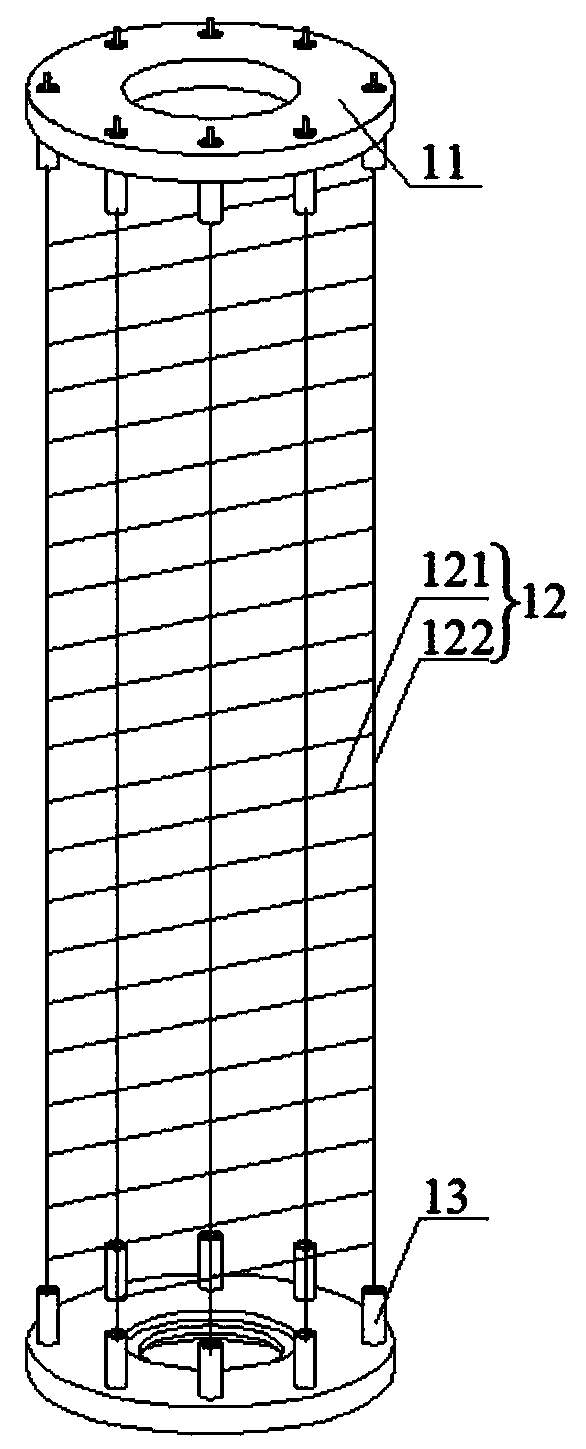

[0034] see figure 1 with image 3 In this embodiment, a prefabricated pile is provided, including a pile body 1 formed of concrete (that is, formed by pouring concrete), end plates 11 arranged at both ends of the pile body 1, and a reinforcement cage 12 arranged in the pile body 1, The reinforcement cage 12 includes several main reinforcements 121 arranged along the length direction of the pile body 1 and reinforcements 122 spirally surrounding the main reinforcements 121. In this embodiment, the pile body 1 is a cylindrical structure, and the main reinforcements 121 are close to the pile body 1. The outer walls are arranged in a ring. see figure 2 , several connecting cylinders 13 are vertically embedded in the terminal plate 11, the outer ends of the connecting cylinders 13 are flush with the surface of the terminal plate 11, the two ends of the main ribs 121 extend outward through the connecting cylinders 13, and the connecting cylinders 13 are sealed Filled with colloi...

Embodiment 2

[0038] see Figure 5 , In this embodiment, a connection structure of prefabricated piles is provided, and the connection structure can connect two prefabricated piles up and down into one body. The connection structure of the prefabricated piles includes a cylindrical connecting body 2 tightly connected between the prefabricated piles 5, the two ends of the cylindrical connecting body 2 are embedded with a connecting cylinder 13 corresponding to the main reinforcement of the prefabricated piles 5, and the two prefabricated piles 5 The main rib 121 extends to the connecting cylinder 13 of the cylindrical connecting body 2, and a sleeve 3 is set on the cylindrical connecting body 2, and the gap between the sleeve 3 and the side wall of the cylindrical connecting body 2 and the connecting cylinder 13 are filled There are colloids.

[0039] see Figure 10 , the connection structure of the prefabricated piles provided in this embodiment can be tightly connected between two prefab...

Embodiment 3

[0046] On the basis of Embodiment 2, another connection structure of prefabricated piles is provided in this embodiment, and a casing 4 is also sleeved on the outer walls of the sleeve 3 and the upper and lower two prefabricated piles 5, see Figure 12 with Figure 13 , the casing 4 is a separate structure, including two identical semi-annular casings 41, the semi-annular casings 41 are combined to form a complete casing 4, and on the side wall of the joint of the two semi-annular casings 41 A plurality of horizontal holes 414 are correspondingly embedded, and bolts are connected in the horizontal holes 414, and colloid is also filled in the horizontal holes 414; several snapping structures are also provided at the joint of the half-ring casing 41, and the snapping structures are in the The protruding part 411 extending outward from the side wall of the half-ring casing 41 at the splicing part, and the notch 412 correspondingly embedded in the side wall of the other half-ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com