Toughening prestressed centrifugal concrete pile

A concrete pile and prestressing technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of insufficient horizontal bearing capacity of pile foundation, large amount of steel used, brittle fracture of square piles, etc. Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

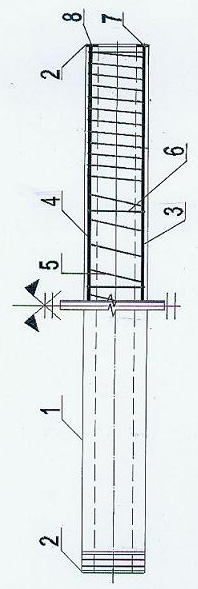

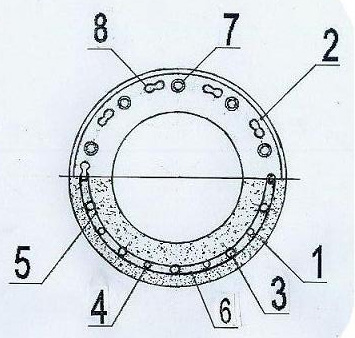

[0016] Because the square pile structure diagram except the square and inner circle is the same as the pipe pile and omitted, the present invention is further described as follows by taking the pipe pile structure diagram as an example:

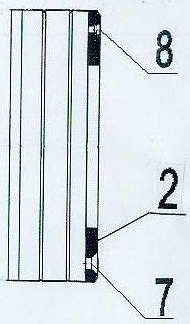

[0017] Referring to the attached drawings, 1 in the figure is the centrifugal concrete pile body, 2 is the end plate, 3 is the non-prestressed main reinforcement, 4 is the prestressed main reinforcement, 5 is the spiral stirrup, 6 is the erecting stirrup, and 7 is the anchorage of the non-prestressed main reinforcement Hole 8 is the anchoring hole of the prestressed main reinforcement.

[0018] The toughened prestressed centrifugal concrete pile of the utility model includes a centrifugal concrete pile body 1, a prestressed main reinforcement 4, a spiral stirrup 5, two end plates 2 and a prestressed main reinforcement anchor hole 8, and also includes a non-prestressed main reinforcement 3 and non-prestressed main reinforcement anchor holes 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com