Space constraint multi-cavity pipe-in-pipe steel bar concrete huge column and construction method

A reinforced concrete and space-constrained technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of insufficient ductility, poor structural integrity, and less load, so as to improve the three-dimensional compressive strength and bearing capacity, and improve the strength and vertical Load bearing capacity, reduced shrinkage and creep effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to illustrate the technical solutions of the present invention in detail, specific embodiments are given below in conjunction with the accompanying drawings.

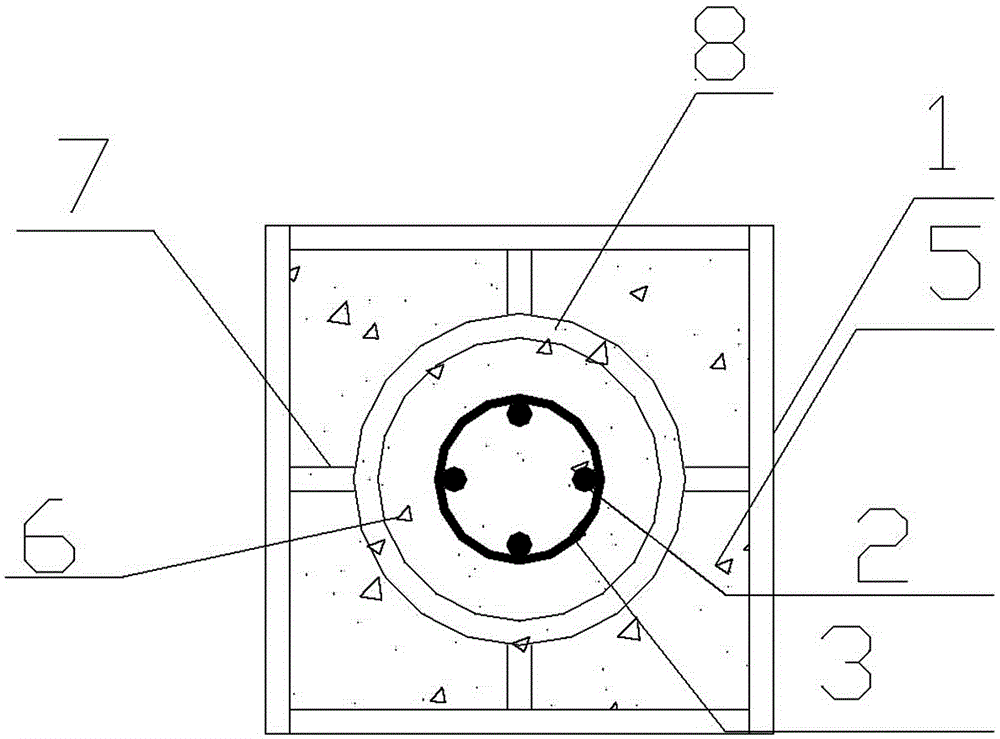

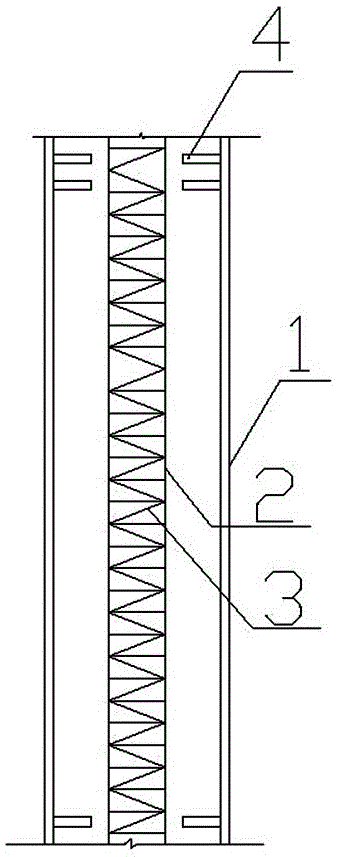

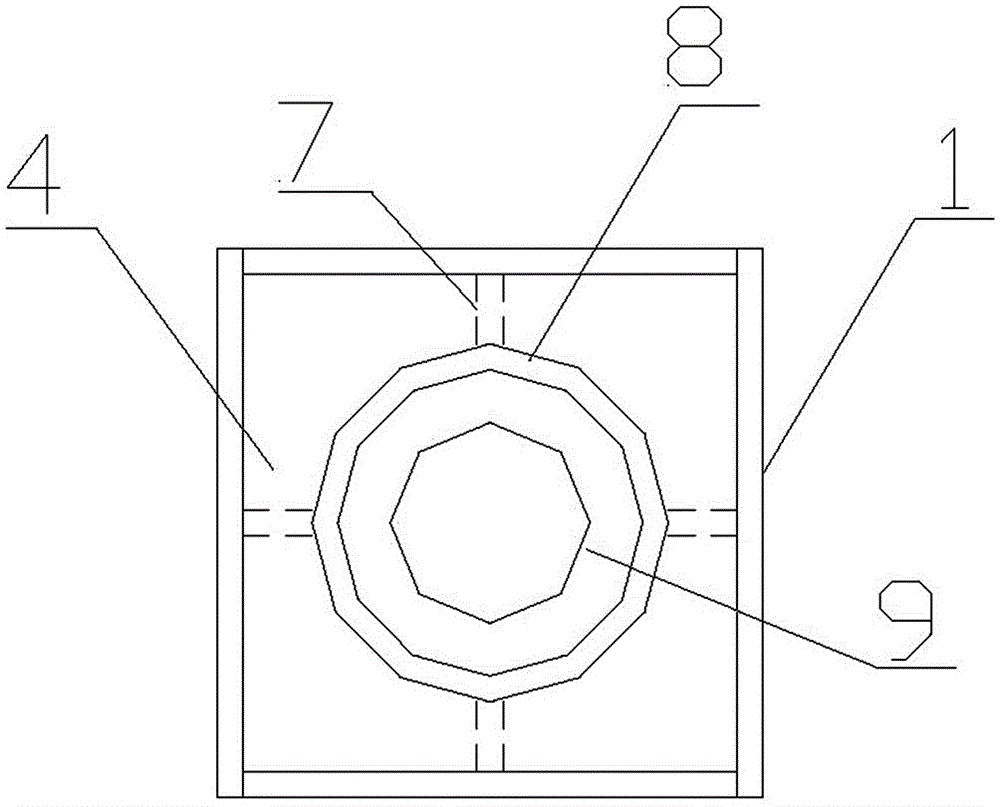

[0048] see Figure 1 to Figure 3 ,in, figure 1 is the cross-sectional view of multi-cavity tube-in-tube reinforced concrete megacolumn; figure 2 is the steel bar distribution of multi-cavity tube-in-tube reinforced concrete megacolumns; image 3It is the distribution of steel pipes in multi-cavity pipe reinforced concrete giant columns. The space-constrained multi-cavity tube-in-tube reinforced concrete giant column shown in the figure includes a core steel tube concrete part and an outsourcing steel tube concrete part, wherein the core steel tube 8 forms an inner cavity, and the inner cavity is filled with inner cavity concrete 6. Wherein, the core steel pipe 8 can be a single steel pipe or multiple steel pipes; wherein, an outer chamber is formed between the core steel pipe 8 and the outsourcing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com