Drill bit system for root-shaped mixing pile

A technology of mixing piles and drill bits, which is applied in the direction of drill pipes, drill pipes, sheet pile walls, etc., can solve the problems that the structural performance of mixing piles cannot be fully exerted reasonably, the engineering quality cannot be well guaranteed, and the replacement rate of pile body area is high. Achieve the effects of saving labor, simple and practical structure, and saving construction project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

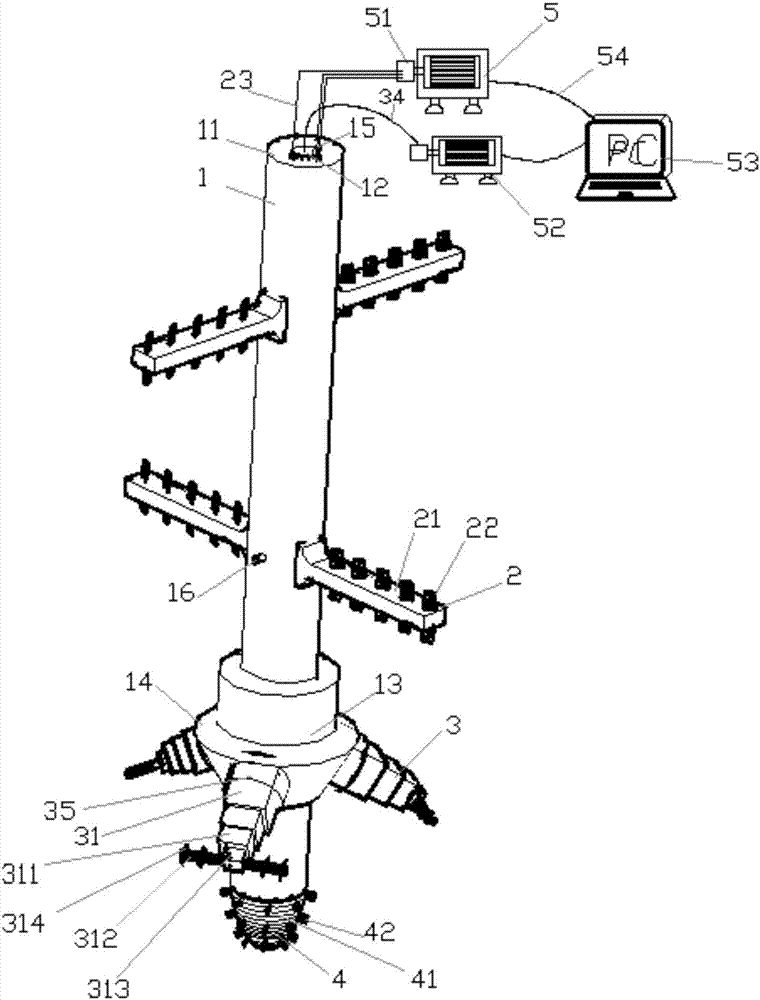

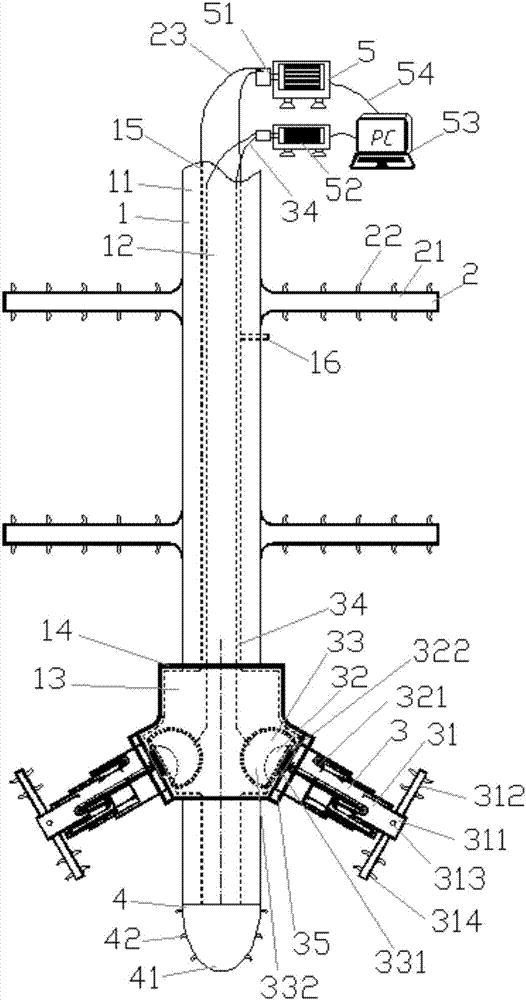

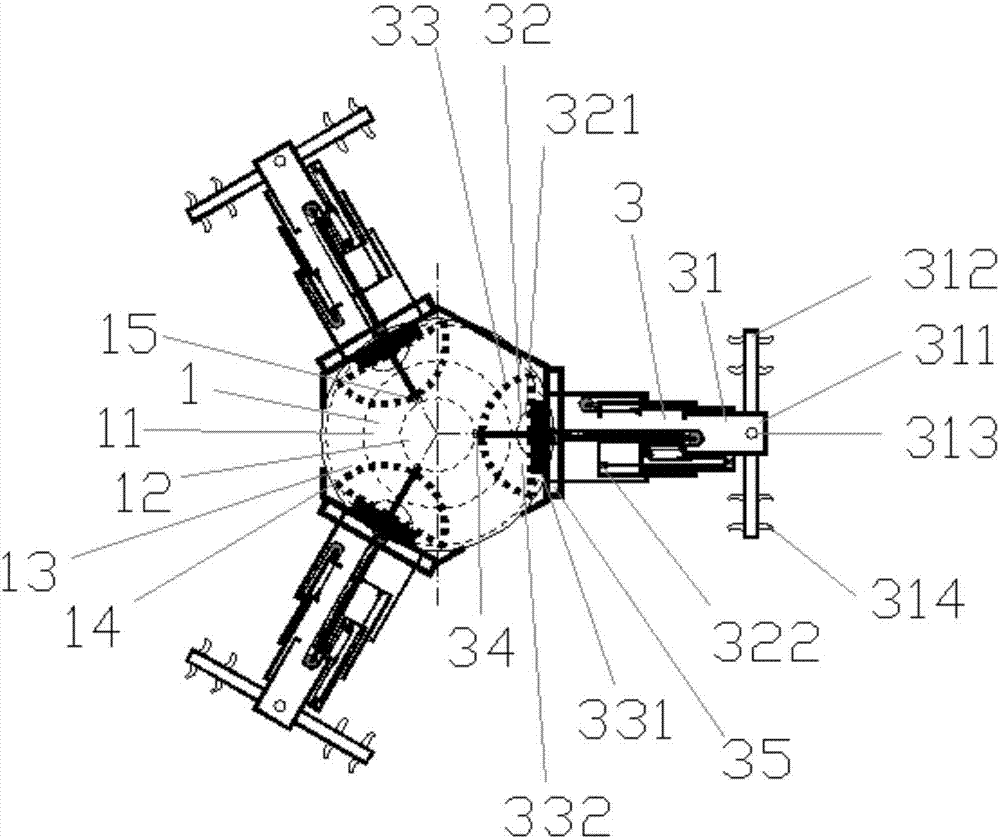

[0028] Such as Figure 1 to Figure 3 As shown, a drill bit system of a root-shaped stirring pile of the present invention includes a drill shaft 1, a general stirring structure 2, a telescopic stirring strut structure 3, a drill bit top structure 4 and a stirring shaft adjustment power system 5; 1 includes the main drill rod 11, the drill shaft cavity 12, the built-in cavity area 13 of the telescopic support arm, the reinforcing rib ring structure 14, the inner transmission groove 15 and the spray hole 16; the main drill rod 11 is the outer cylinder of the drill shaft 1 body, the drill shaft cavity 12 is arranged inside the drill shaft 1, the reinforcing rib ring structure 14 is arranged on the outer wall of the drill shaft 1, the built-in cavity area 13 of the telescopic support arm is arranged inside the reinforcing rib ring structure 14, and the internal transmission Gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com