Vacuum preloading and soil body surface solidification combined processing technique

A technology of joint treatment and surface solidification, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as reducing the later settlement of the foundation, reduce the later settlement, improve the horizontal bearing capacity, and reduce the later maintenance cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

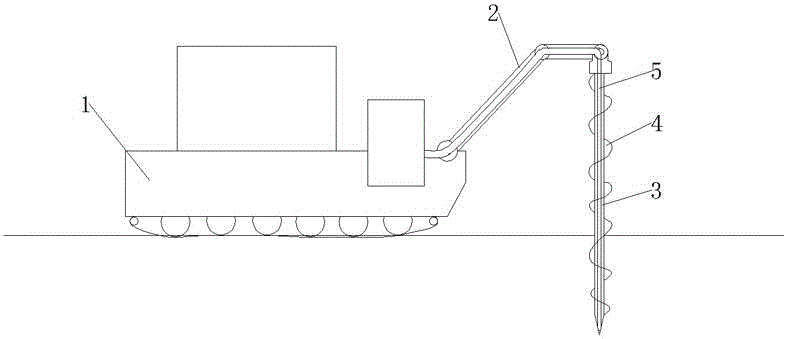

[0008] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0009] The combined treatment process of vacuum preloading and soil surface solidification provided by the present invention comprises the following steps: A. Arranging vertical drainage boards in the dredging mud / silt / waste mud pool, the top of the vertical drainage boards is connected to a drainage pipe, and the drainage The pipeline is connected to the outside, and the top of the soil in the vacuum precompression water reduction tank and the drainage pipe are covered with a sealing cloth, and the edge of the sealing cloth is sealed with the soil by a sealing structure, and the vacuum pump is connected to the drainage pipe and extracts the water in the soil; B . After the vacuum preloading is completed, remove the vacuum seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com