Grouting system for enhancing bearing capacity of offshore wind power pile foundation and construction method

A technology of grouting system and offshore wind power, which is applied in the direction of infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of limited length and pile foundation bearing capacity that cannot meet the design requirements, and achieve the reduction of length and man-machine material input Economical and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

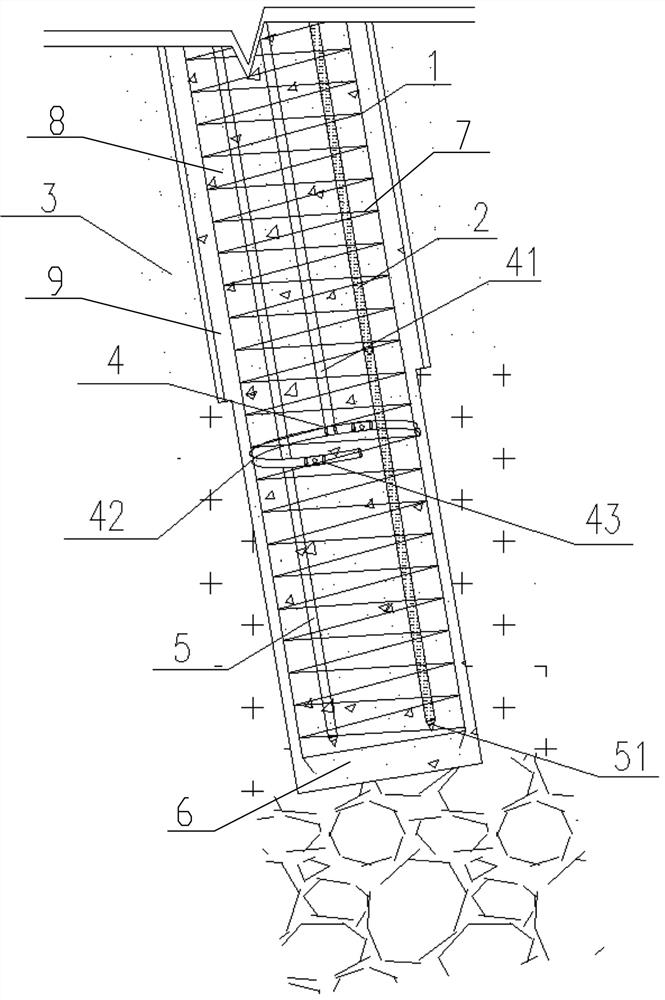

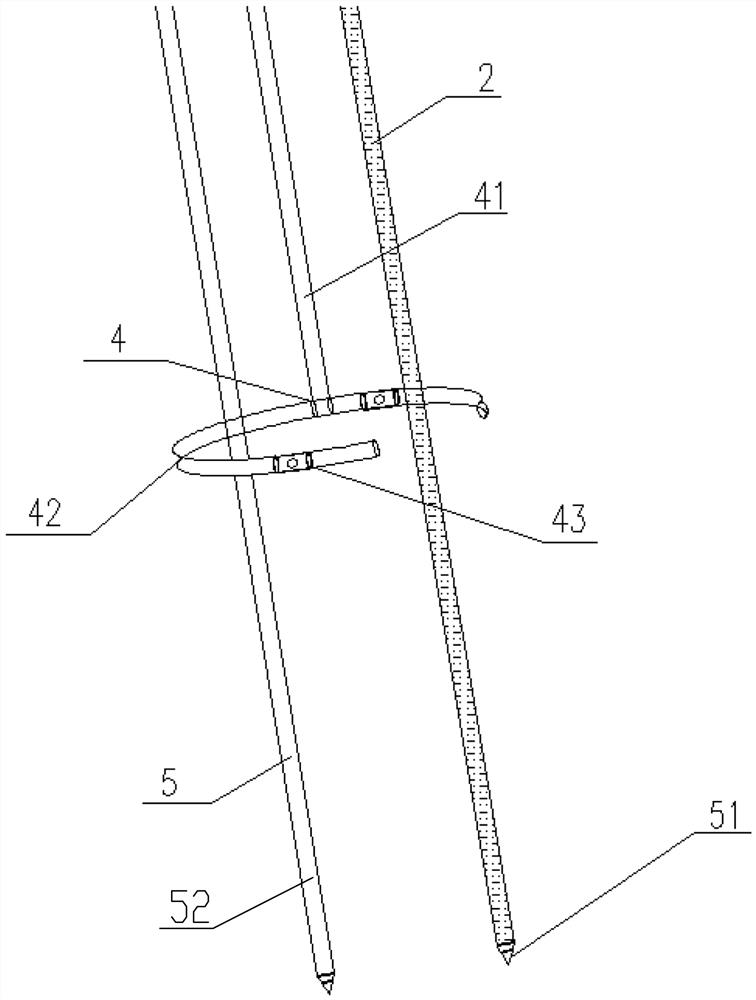

[0038] see Figure 1-2 , a grouting system for strengthening the bearing capacity of offshore wind power pile foundations, which includes a pipeline installation structure 1 for installing the grouting system; Pile side grouting system 4 and pile bottom grouting system 5 for grouting the pile bottom of cast-in-place pile 8; said pile-side grouting system 4 is connected with the grouting system, and injects grout 2 into cast-in-place pile 8 The pile side gap 9 between the outer wall of the cast-in-situ pile 8 and the seabed foundation layer 3; the pile bottom grouting system 5 is connected to the grouting system, and the grout 2 is injected between the pile bottom of the cast-in-situ pile 8 and the seabed foundation layer 3 The pile bottom gap between 6. By adopting the above-mentioned grouting system, after the cast-in-situ pile 8 is poured, secondary grouting can be performed, and the grout can infiltrate and split the pile body and the surrounding soil, and then solidify, t...

Embodiment 2

[0049] The construction method of grouting by using the grouting system for strengthening the bearing capacity of the offshore wind power pile foundation is characterized in that: through the grouting system embedded in the cast-in-place pile 8, the cast-in-situ pile 8 is formed and the secondary grouting is performed, Through the grout, the pile body and the surrounding soil will first be infiltrated and split, and then solidified, thereby increasing the bearing capacity.

[0050] The construction method for grouting the grouting system for strengthening the bearing capacity of the offshore wind power pile foundation is characterized in that it specifically includes the following steps:

[0051] Step 1: Select the wind turbine foundation under typical geological conditions with insufficient bearing capacity to carry out the pile foundation bearing capacity test, determine the standard values of the vertical compressive and pullout ultimate bearing capacity of the pile founda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com