Non-prestressed centrifugal concrete pile

A non-prestressed, concrete pile technology, applied in sheet pile walls, structural elements, building components, etc., can solve the problems of insufficient horizontal bearing capacity of the foundation and low production efficiency, and achieve high production efficiency, simple production method, vertical The effect of high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

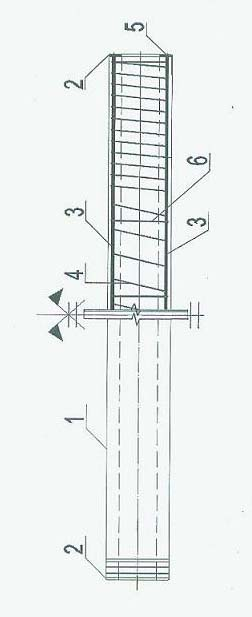

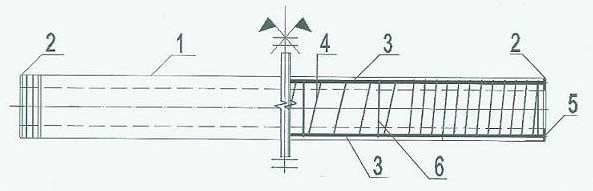

[0015] Below in conjunction with accompanying drawing, the present invention is further described as follows:

[0016] The non-prestressed centrifugal concrete pile of the present invention has a structure comprising a centrifugal concrete pile body 1, a non-prestressed main reinforcement 3, a spiral stirrup 4, and two end plates 2, and the non-prestressed main reinforcement 3 is longitudinally distributed and welded or bound on On the spiral stirrup 4, the two ends of the non-prestressed main reinforcement 3 are respectively welded or anchored to the two end plates 2 through anchor holes 5.

[0017] In order to prevent the reinforcement skeleton from sagging, erection stirrups 6 can be added. The erection stirrups are circular steel bars, distributed at intervals of 1m to 2m and welded or bound on the outside of the spiral stirrups 4 and the non-prestressed main reinforcement 3 .

[0018] When the non-prestressed centrifugal concrete pile is a non-prestressed centrifugal conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com