A construction method for hole forming and side wall grouting of cast-in-situ piles for coral sand foundation

A construction method and technology of cast-in-situ piles, which are applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of difficult hole formation, low lateral resistance, and slow driving, etc., so as to reduce particle crushing and improve pile side Frictional resistance, the effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

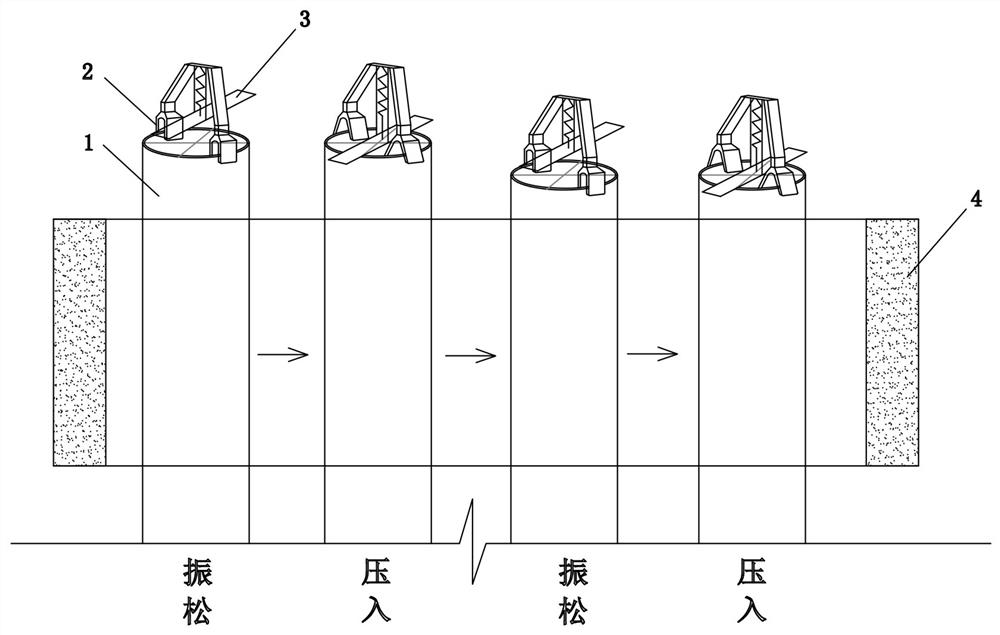

[0022] The present invention adopts the method of alternate operation of vibration and static pressure to carry out the hole-forming construction of the steel casing of the cast-in-situ pile, and carries out the side grouting of the pile while pulling out the steel casing. The specific construction includes the following steps:

[0023] a. Hole forming of cast-in-situ piles

[0024] See attached figure 1 , adopt the method of alternate operation of vibration and static pressure, use the telescopic static pressure device 3 and the clamp 2 to drive the steel casing 1 into the coral sand foundation 4, and use the method of water flushing to remove the sand in the steel casing 1 after the hole is formed. Take it out, and use water instead of sand to clean the hole.

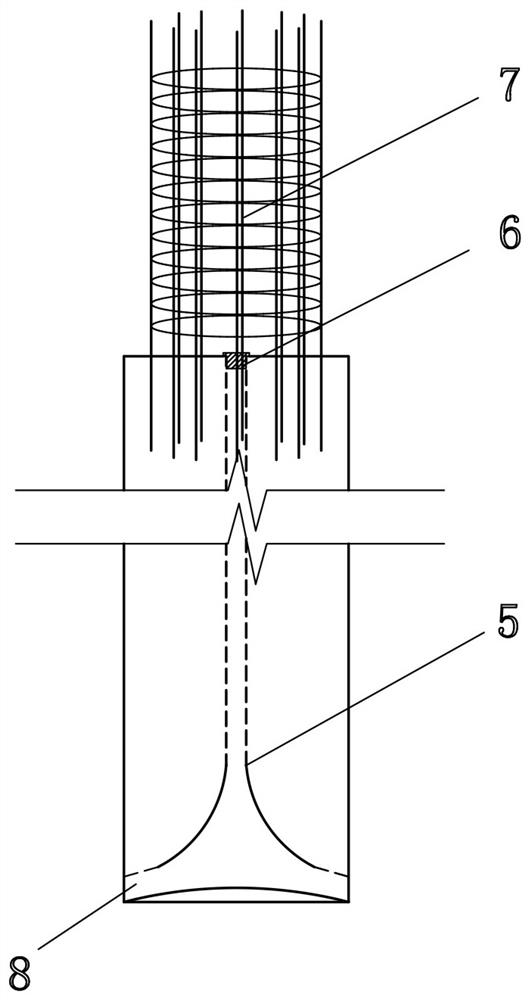

[0025] b. Place the reinforcement cage

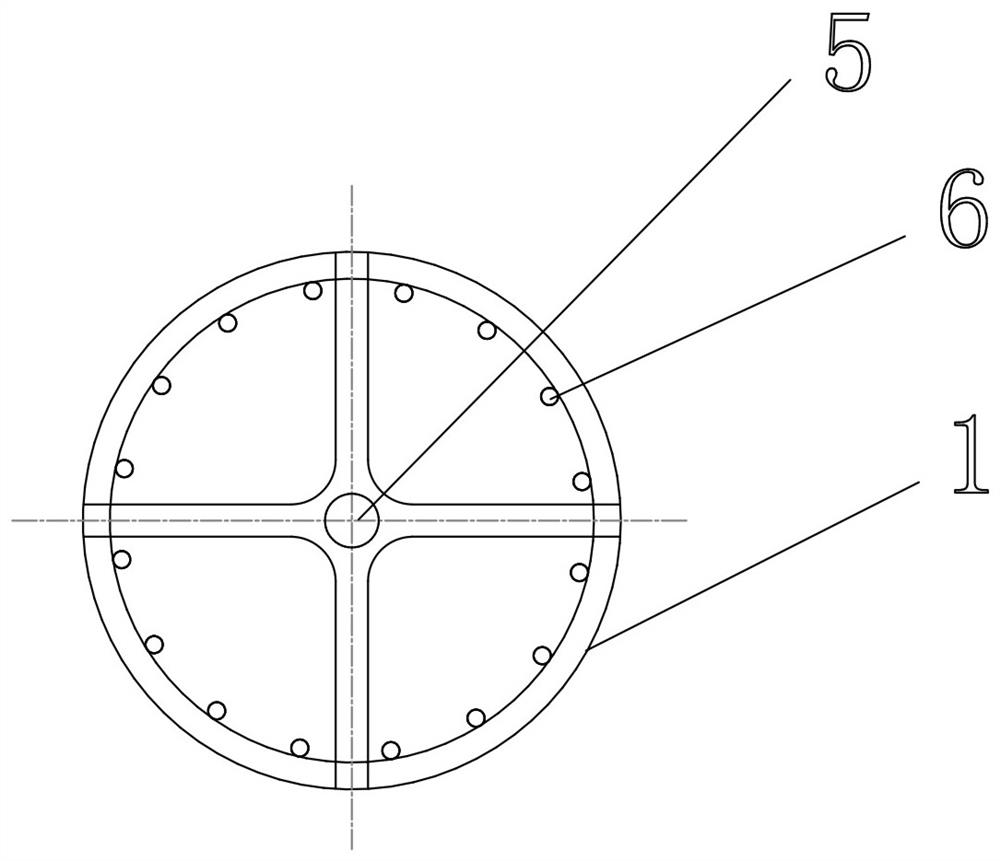

[0026] See attached Figure 2 ~ Figure 3 , after the cast-in-place pile is drilled, hang the reinforcement cage 7 and the pre-embedded grouting casing 5 in the steel casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com