Settlement prevention method for bridge pile foundation

An anti-settlement and pile foundation technology, applied in the direction of infrastructure engineering, construction, etc., can solve problems such as inconsistent settlement of road-bridge lap joints, increased additional stress on the upper structure, and unsteady driving of vehicles, so as to improve the radial support force and anti-corrosion torsional ability, avoid deformation or cracking, and reduce the effect of uneven settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0042] Example 1

[0043] A sedimentation displacement of the load, including: Piles in the pile, the soil under the pile end is transmitted to the upper portion of the load occurred to the load of the pile side, due to the diffusion of the pile side, diffused to the pile end The end of the pile ends is compressed, so the end of the pile also produces a downward displacement; the pile is elastically deformed by the elastic material after being loaded, so the top of the pile will occur, which can be seen from the above Under the action of pile top vertical load and pile circumference, the sedimentation displacement of the pile is caused.

[0044] A anti-deposition method of bridge pile foundation, including the following steps:

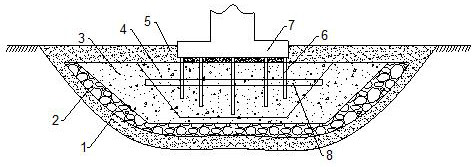

[0045] S1, excavation pits at the specified soil layer 1, paved the compensation layer 2 above the foundation pit;

[0046] S2, a first concrete layer 3 is paved over the compensation layer 2, and after fixing the positioning block 8 of the pile base 6 and t...

Example Embodiment

[0050] Example 2

[0051] Combine figure 1 The foundation pit is opened at the specified soil layer 1, and the compensation layer 2 and the concrete layer are seated sequentially in the foundation pit, and the thickness of the soil layer 1 is not 20-25 cm. Sie gravel is used as the compensation layer 2 to improve the bearing capacity of the soil layer 1, loosely pellets such as gravel, gravel, etc., such materials, such materials, can make a buffer of the subgrade deformation, Effectively reduce the additional stress of the base structure caused by the street base settlement, set the stiffness compensation layer in the soil layer subgrade, can effectively reduce the working sedimentation of the soil layer subgrade, and the stiffness compensation layer uses a material pair with large rebound modulus The effect of roadbed stiffness compensation is more obvious.

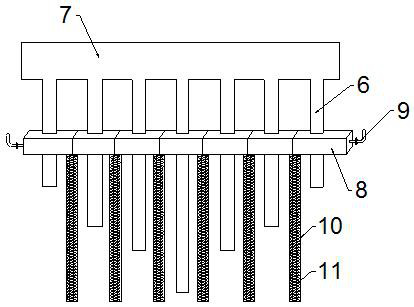

[0052] The concrete layer is provided with a pile base 6, and the top end of the pile found 6 is connected to a junction ...

Example Embodiment

[0054] Example 3

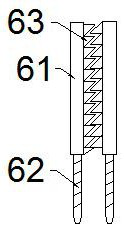

[0055] Based on the basis of Example 2, the combination image 3 with Figure 4 The pile base 6 includes a rod 61 and a screw pile 62 provided at the bottom of the strut 61, the sidewall of the strut 61 is provided on the sidewall portion 63, and the plurality of roots 6 The billet 61 between the pile found 6 is engaged with each other by a zigzag portion 63, and the outer portion 63 between the struts 61 between the adjacent pile base 6 is outside the protective sleeve protection, and several root piles 6 A constituent block 8 is connected between the positioning blocks 8 between adjacent pile bases 6 forms a whole, and the positioning block 8 on the outer side of the launching 7 is connected to the concrete by anchor 9, respectively. In the layer, the pile side is made to improve the pile side by adding and subtraction, and the carrying capacity of the pile side is made by the pile side, and the bearing capacity of the pile side is increased, and the occurrence ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com