Variable diameter plastic sleeve mixed pile for reinforcing thick-covering and deep-burying soft soil layer and piling method

A technology of plastic sleeve and covering layer, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of waste and high cost of rigid piles, and achieve the effects of cost reduction, high pile side friction resistance, and project cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

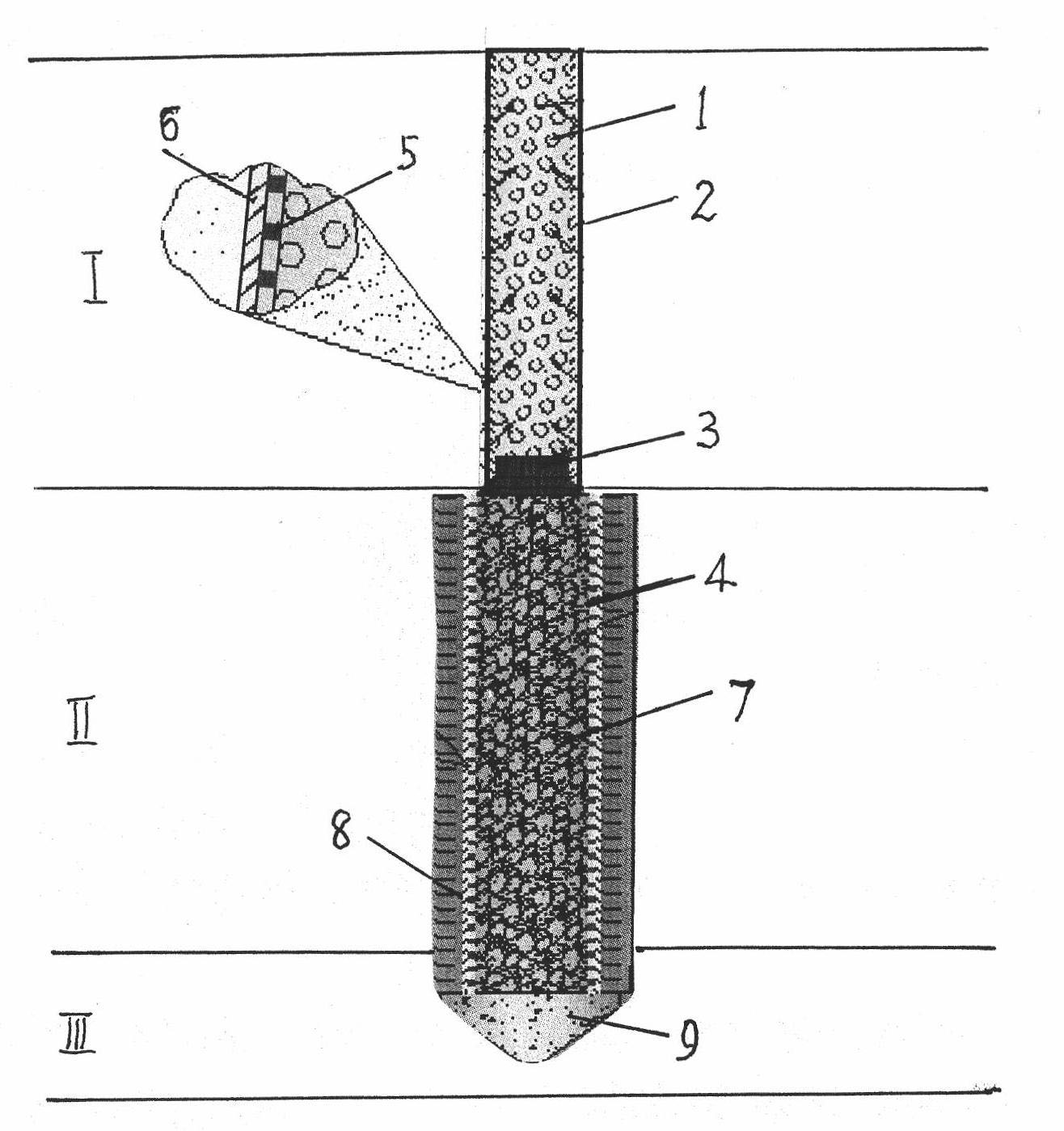

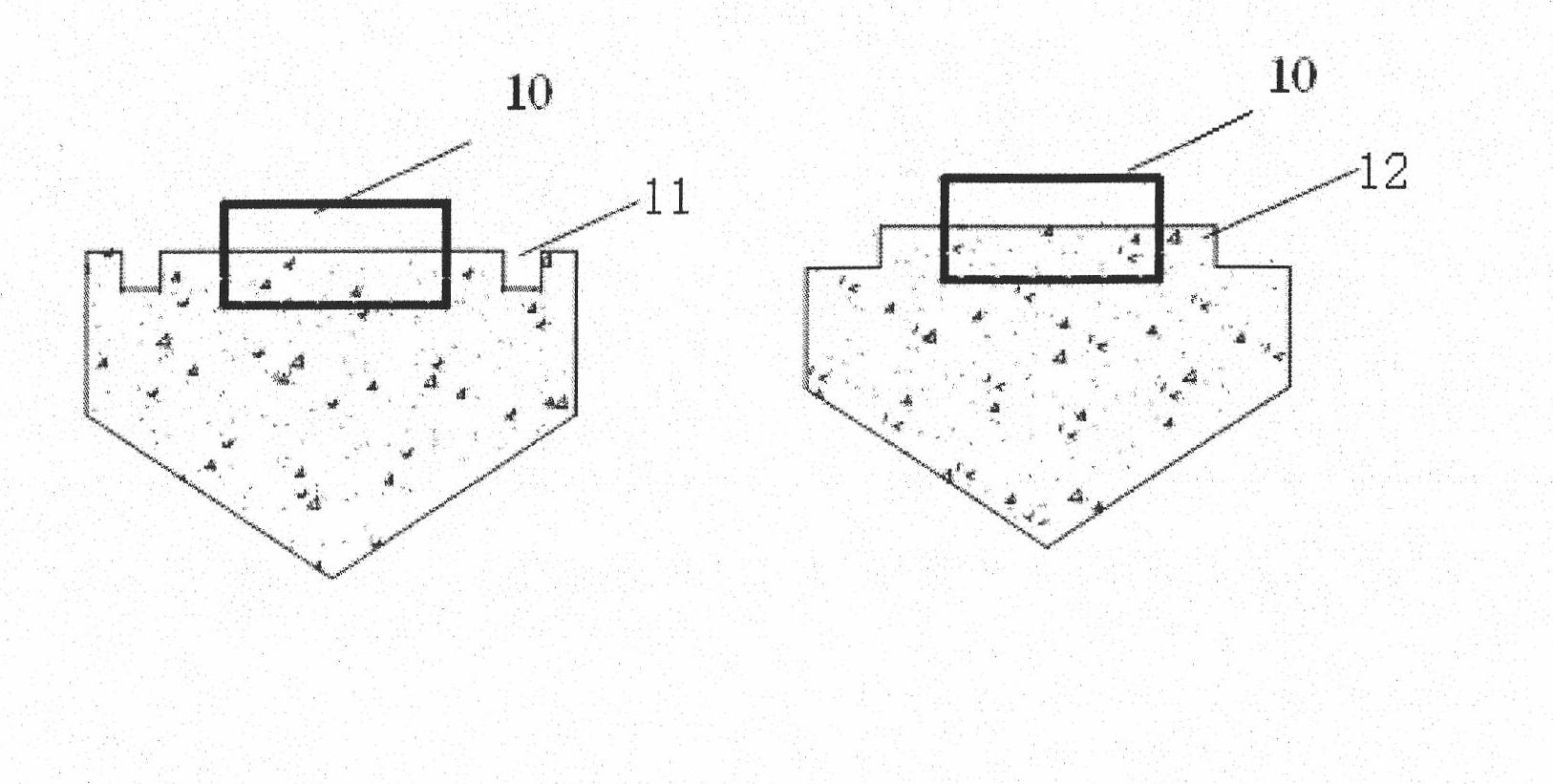

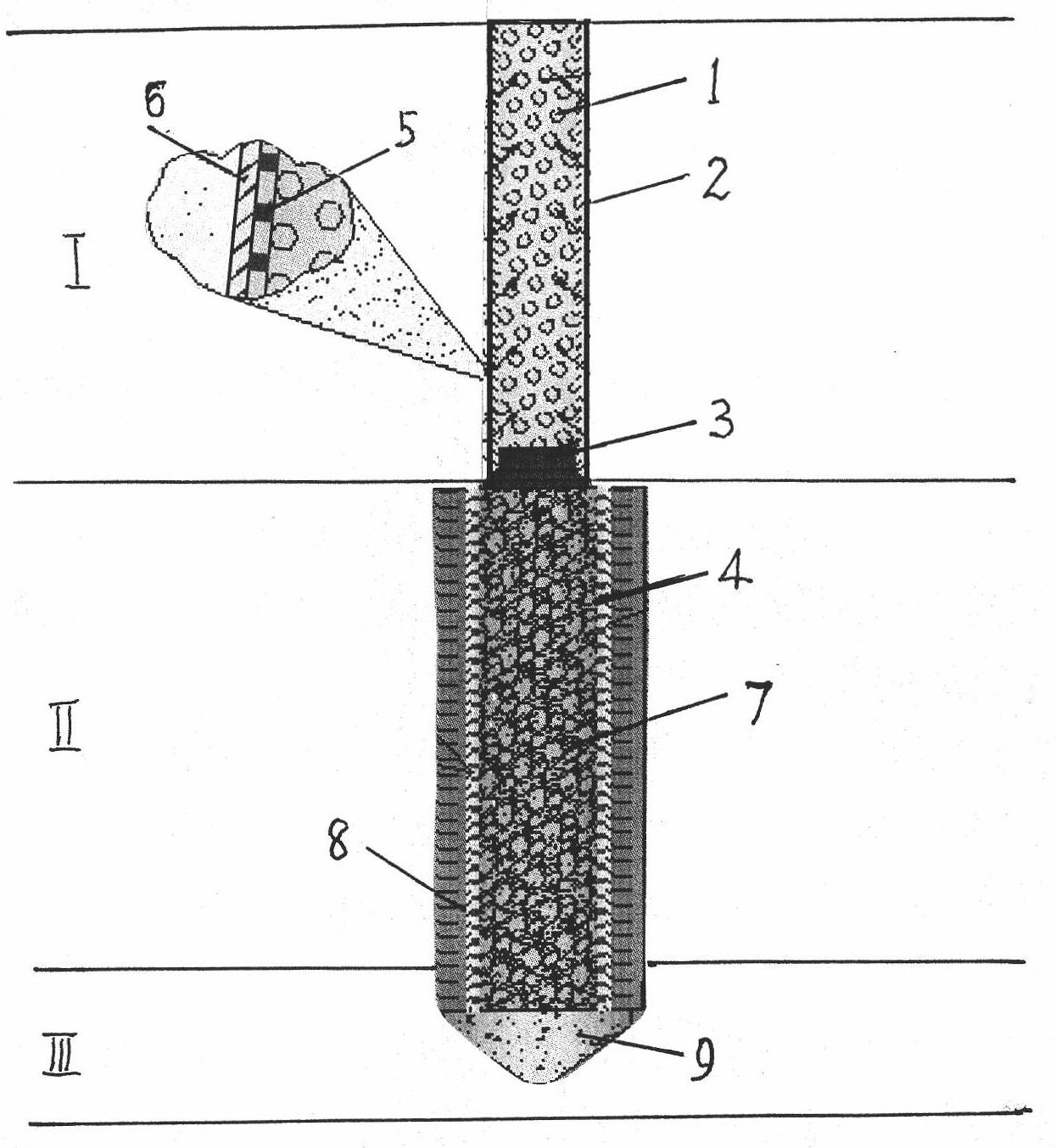

[0037] Such as figure 1, make the prefabricated enlarged pile point 9 with the specially researched and developed pile tip mold; according to the distribution situation of thick cover layer I, deep buried soft soil layer II, hard soil layer or relatively hard soil layer III, prepare threaded plastic casing 2, 4. The sleeves 2 and 4 are drilled at a certain distance along the pile body according to the design requirements; the sleeves 2 and 4 are firmly connected with variable diameter plastic sleeve joints 3 and glue according to the design pile length. When it is necessary to take over the pipe, use a special joint of the corresponding size to connect, wrap the opening on the side wall with geotextile or filter cloth 3, and then connect the plastic sleeve slightly longer than the designed pile length to the sleeve on the prefabricated pile tip 9 The socket 10 is tightly connected with PVC adhesive glue to form a semi-enclosed space with an upper opening; lift the immersed tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com