Pile mold and construction method of a cast-in-place X-shaped large-diameter hollow directional steel fiber concrete pile

A technology of steel fiber concrete and construction methods, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of increased raw material consumption of steel fiber concrete, failure of steel fibers to exert shear resistance, and low effective utilization of steel fibers , to achieve the effect of increasing vertical bearing capacity, increasing horizontal bearing capacity, and high outer friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

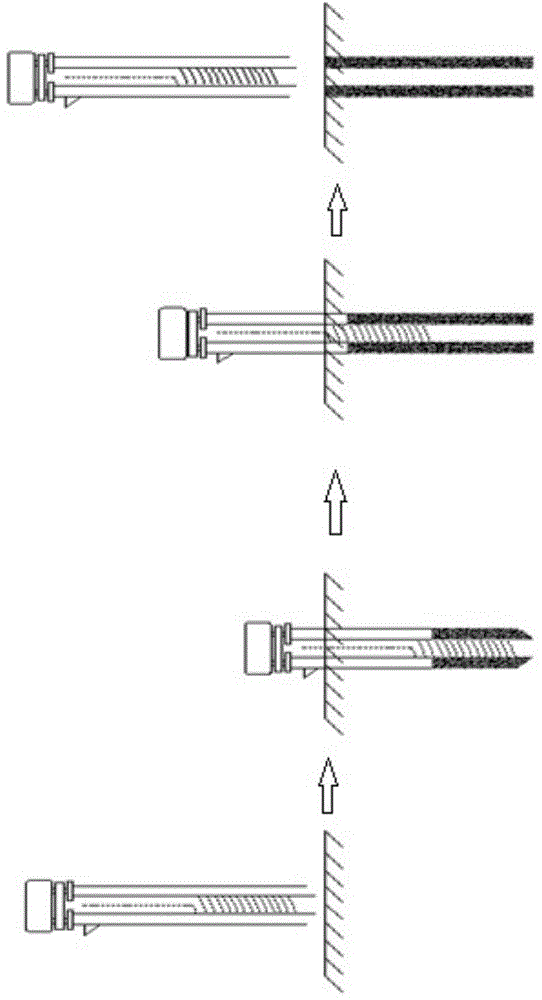

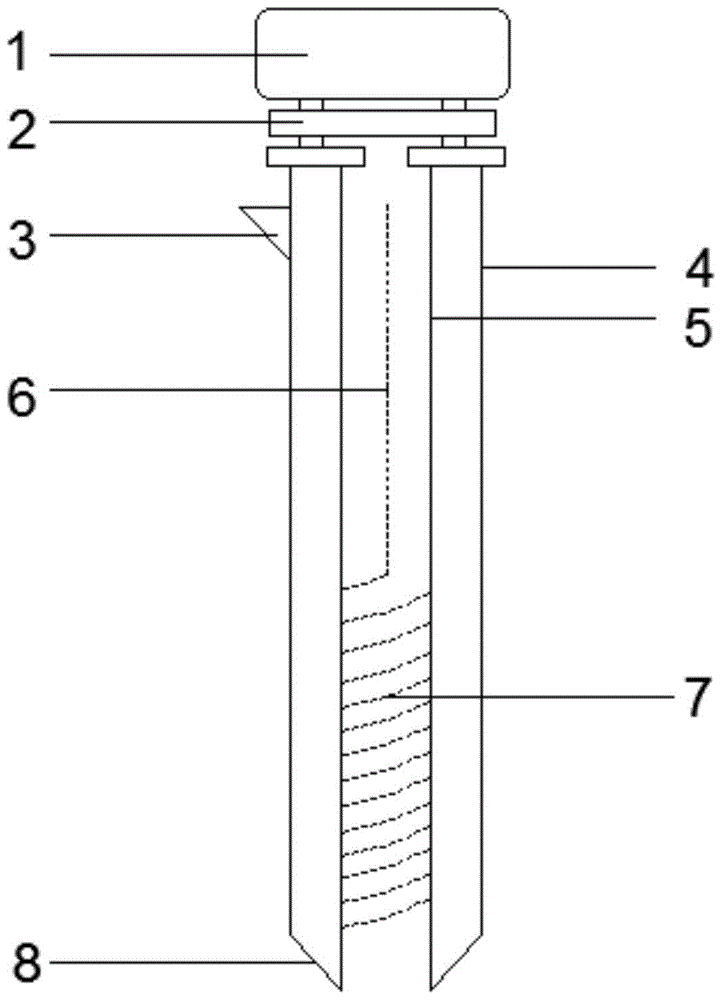

[0032] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

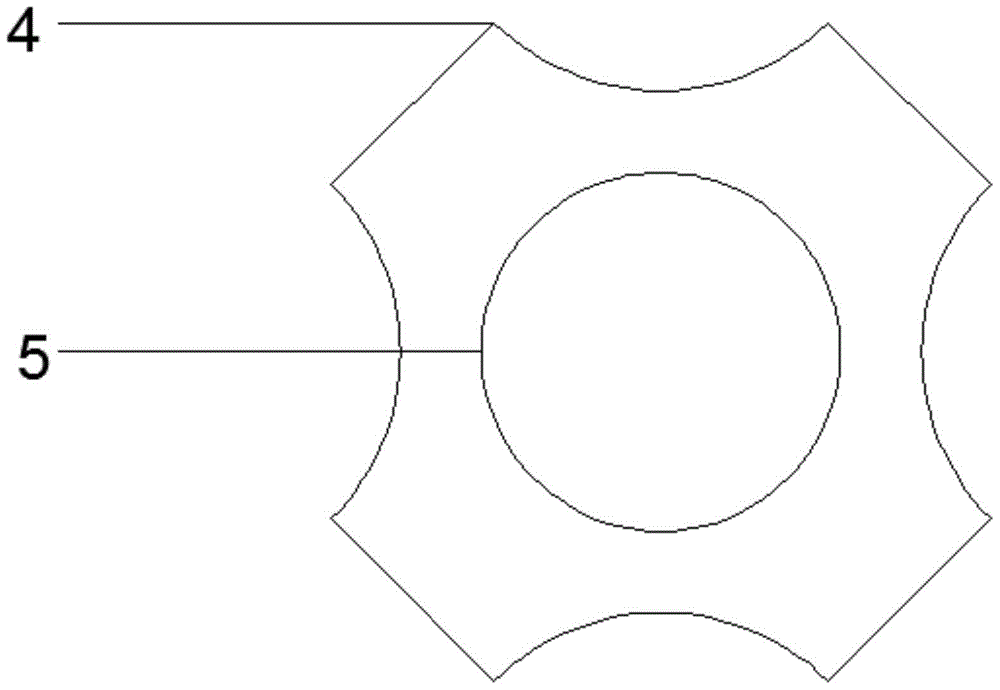

[0033] like figure 2 As shown, the pile form of cast-in-place X-shaped large-diameter hollow directional steel fiber reinforced concrete pile is composed of X-shaped pile formwork outer tube 4 and circular pile formwork inner tube 5 to form a concentric casing cavity structure, and the top of the pile formwork is passed through a detachable The flange plate 2 is connected with the vibrating head 1, and the bottom of the pile form is connected with the movable valve pile shoe 8; the spiral groove of 500 to 600 circles is pre-engraved from the bottom of the inner tube 5 of the circular pile form to 1 / 2 height, and 1 / 2 Two linear grooves are pre-engraved from the height to the top; the DC coil 7 is wound in the spiral groove, and the groove is firmly connected with the self-drying adhesive insulating varnish, and covered with a layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com