A pole piece impregnation method for a soft-pack lithium-ion battery

A lithium ion battery and ion battery technology, applied in the field of lithium ion batteries, can solve problems such as the impact of battery cycle performance, and achieve the effects of improving wetting effect, improving wettability, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

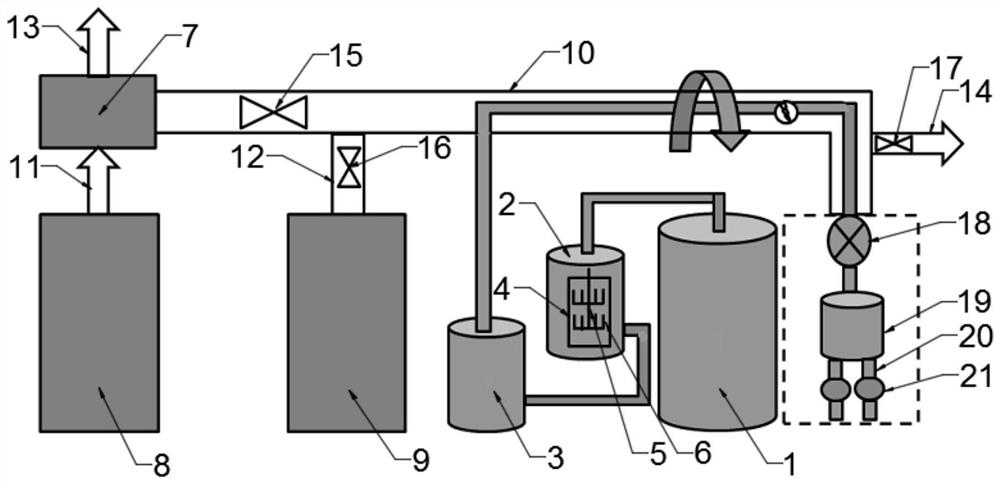

[0060] A pole piece impregnation method for a soft-pack lithium-ion battery, comprising the steps of:

[0061] The first step: before liquid injection, the electrolyte in the electrolyte storage mother tank 1 is transported to the electrolyte storage tank A2 through a pipeline under high pressure, and passes through the stirring device installed in the electrolyte storage tank A2 (stirring speed 15rpm / min ) and a vacuum device (vacuum degree -90KPa) to remove the bubbles in the electrolyte, and transport it to the electrolyte storage tank B3 through the pipeline, and transport it from the electrolyte storage tank B3 to the pipeline to obtain the electrolyte to be preheated.

[0062] The coating process and the liquid injection process are produced at the same time. The waste heat recovery device 7 of the coater is connected to the coating drying system 8 through the first exhaust pipe 11, and recovers the waste heat generated by the oven of the coater. 10. Provide high-tempera...

Embodiment 2

[0071] A pole piece impregnation method for a soft-pack lithium-ion battery, comprising the steps of:

[0072] The first step: before liquid injection, the electrolyte in the electrolyte storage mother tank 1 is transported to the electrolyte storage tank A2 through a pipeline under high pressure, and passes through the stirring device installed in the electrolyte storage tank A2 (stirring speed 15rpm / min ) and a vacuum device (vacuum degree -90KPa) to remove the bubbles in the electrolyte, and transport it to the electrolyte storage tank B3 through the pipeline, and transport it from the electrolyte storage tank B3 to the pipeline to obtain the electrolyte to be preheated. The coating process and the liquid injection process are produced at the same time. The waste heat recovery device 7 of the coater is connected to the coating drying system 8 through the first exhaust pipe 11, and recovers the waste heat generated by the oven of the coater. 10. Provide high-temperature air ...

Embodiment 3

[0081] A pole piece impregnation method for a soft-pack lithium-ion battery, comprising the steps of:

[0082] The first step: before liquid injection, the electrolyte in the electrolyte storage mother tank 1 is transported to the electrolyte storage tank A2 through a pipeline under high pressure, and passes through the stirring device installed in the electrolyte storage tank A2 (stirring speed 15rpm / min ) and a vacuum device (vacuum degree -90KPa) to remove the bubbles in the electrolyte, and transport it to the electrolyte storage tank B3 through the pipeline, and transport it from the electrolyte storage tank B3 to the pipeline to obtain the electrolyte to be preheated. The coating process and the liquid injection process are produced at the same time. The waste heat recovery device 7 of the coater is connected to the coating drying system 8 through the first exhaust pipe 11, and recovers the waste heat generated by the oven of the coater. 10. Provide high-temperature air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com