Pre-bored hole static blasting and manual pile digging auxiliary construction method for hard-rock stratum

A static blasting and construction method technology, applied in excavation, sheet pile wall, foundation structure engineering and other directions, can solve the problems of undetermined blasting range, affecting the uniformity of pile diameter, waste of concrete in the pile body, etc. The effect of improving the side friction resistance of the pile and saving the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

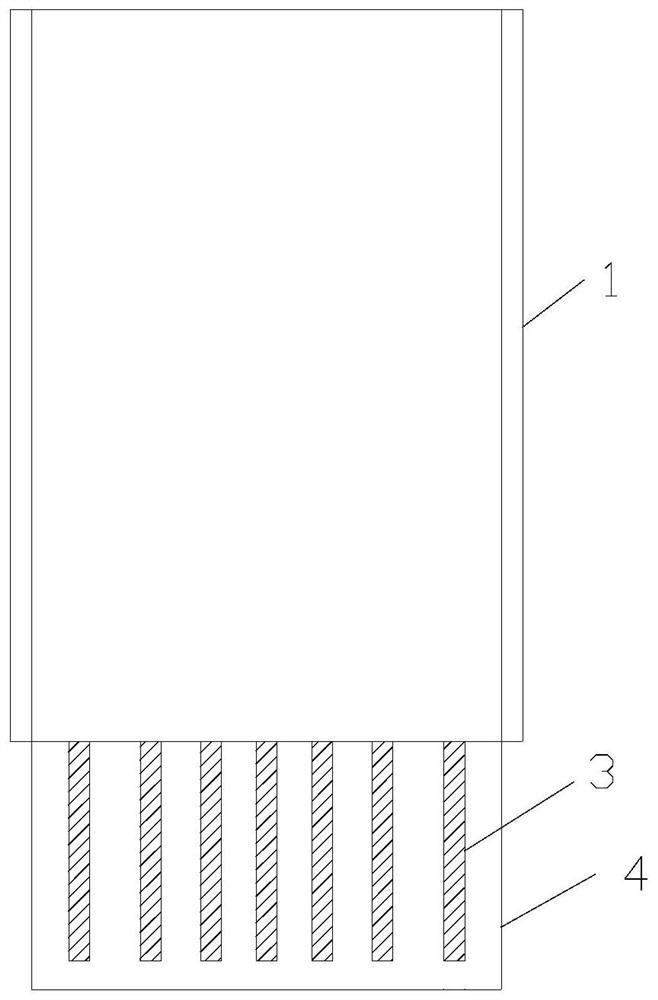

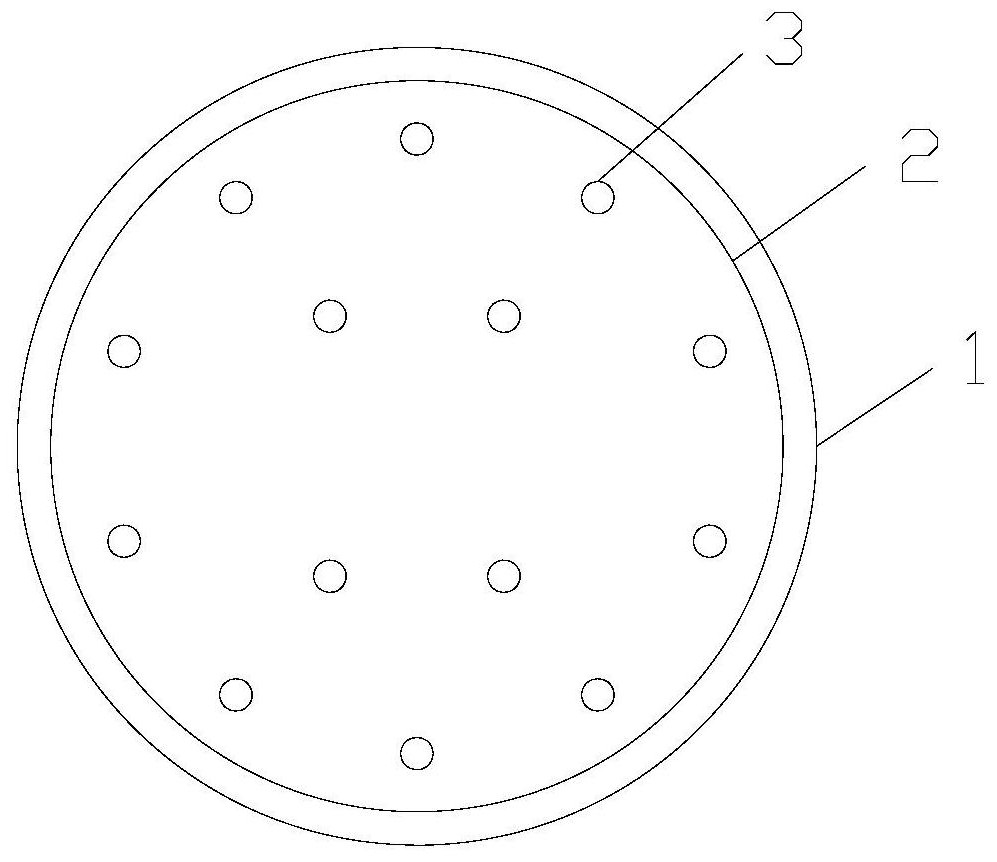

[0019] See Figure 1-2 This embodiment provides a technical solution: a pre-drilled static blasting auxiliary construction method for man-digging piles in hard rock formations, including the following steps:

[0020] S1. Drill a plurality of pre-drill holes along the depth direction of the pile holes 2 within the radial range of the pre-designed pile holes 2 on the hard rock stratum 4, inject expansive cement into the pre-drill holes 3, and then inject water and seal the pre-drill holes. Drilling 3. The diameter of the pre-drilled hole 3 is 20 mm and the length is 50 cm. The plurality of pre-drilled holes 3 includes first drilled holes evenly distributed around the center of the pile hole 2, and a plurality of second drilled holes distributed in a matrix, equilateral triangle or isosceles triangle between the plurality of first drilled holes. Two drilling holes.

[0021] S2. After the hard rock is expanded and cracked under the action of the expansion force of the expansive ceme...

Embodiment 2

[0031] This embodiment provides a technical solution: a pre-drilled static blasting auxiliary construction method for human-excavated piles in hard rock formations, including the following steps:

[0032] S1. Drill a plurality of pre-drill holes 3 along the depth direction of the pile holes 2 within the radial range of the pre-designed pile holes 2 on the hard rock stratum 4, inject expanded cement into the pre-drill holes 3, and then inject water. The diameter of the pre-drilled hole 3 is 80mm and the length is 150cm. The plurality of pre-drilled holes 3 includes first drilled holes evenly distributed around the center of the pile hole 2, and a plurality of second drilled holes distributed in a matrix, equilateral triangle or isosceles triangle between the plurality of first drilled holes. Two drilling holes.

[0033] S2. After the hard rock is expanded and cracked under the action of the expansion force of the expansive cement, the pile hole 2 is excavated in the hard rock strat...

Embodiment 3

[0037] This embodiment provides a technical solution: a pre-drilled static blasting auxiliary construction method for human-excavated piles in hard rock formations, including the following steps:

[0038] S1. Drill a plurality of pre-drill holes 3 along the depth direction of the pile holes 2 within the radial range of the pre-designed pile holes 2 on the hard rock stratum 4, inject expanded cement into the pre-drill holes 3, and then inject water. The diameter of the pre-drilled hole 3 is 80mm and the length is 150cm. The plurality of pre-drilled holes 3 includes first drilled holes evenly distributed around the center of the pile hole 2, and a plurality of second drilled holes distributed in a matrix, equilateral triangle or isosceles triangle between the plurality of first drilled holes. Two drilling holes.

[0039] S2. After the hard rock is expanded and cracked under the action of the expansion force of the expansive cement, the pile hole 2 is excavated in the hard rock strat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com