Concrete filled steel pipe pile and manufacturing method thereof

A steel pipe concrete pile and a manufacturing method technology, applied in the direction of manufacturing tools, sheet pile walls, ceramic molding machines, etc., can solve problems such as difficult quality assurance, insufficient pile body bearing capacity, small side friction resistance, etc., to avoid quality difficulties Guarantee and improve pile side friction resistance and increase the effect of occlusal friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

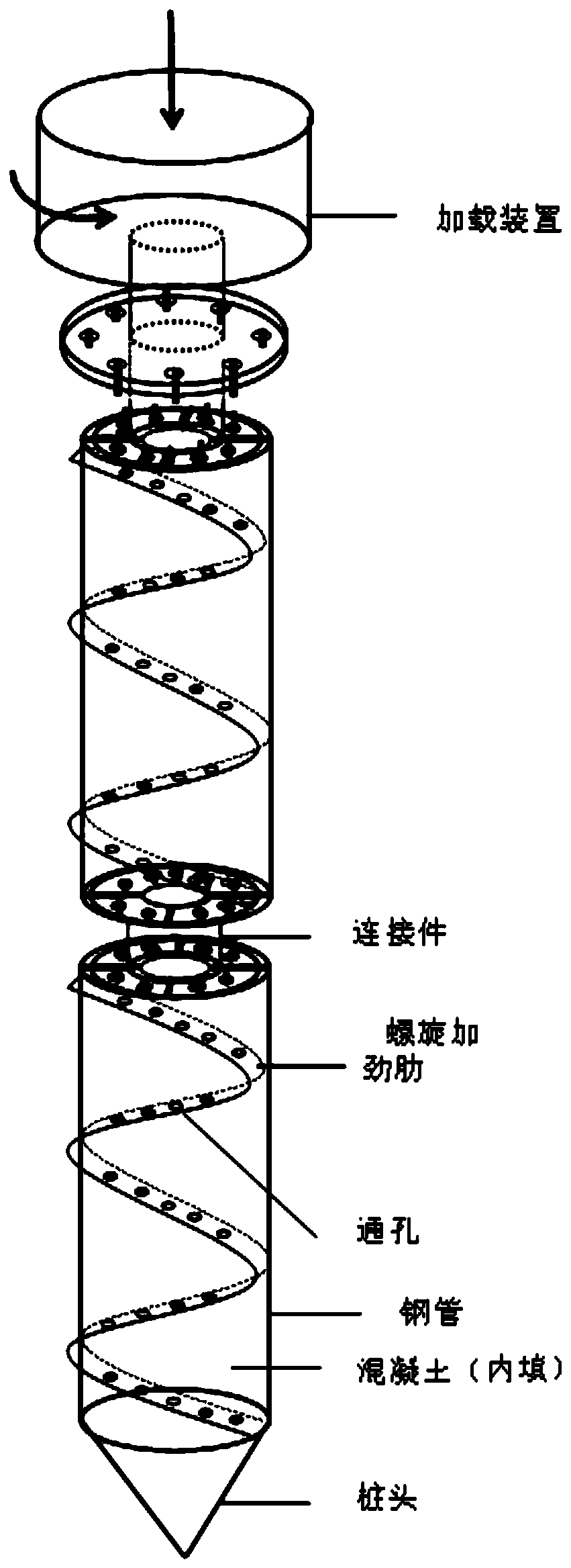

[0031] A steel pipe concrete pile of the present invention has a structure such as figure 1 As shown, it includes multi-section steel pipes. Concrete is poured inside each section of steel pipes. The head and tail of multi-section steel pipes are connected by connectors to form a pile body. The top of the pile body is connected to the loading device through connectors, and the loading device drives the pile body to press into the soil. The bottom end of the pile body is fixed to the conical pile head to fix the pile body. The outer wall of each section of steel pipe is fixed with spiral stiffeners from one end to the other end along the circumference. The spiral stiffeners on the pile body formed by multi-section steel pipes A rotation is continuous.

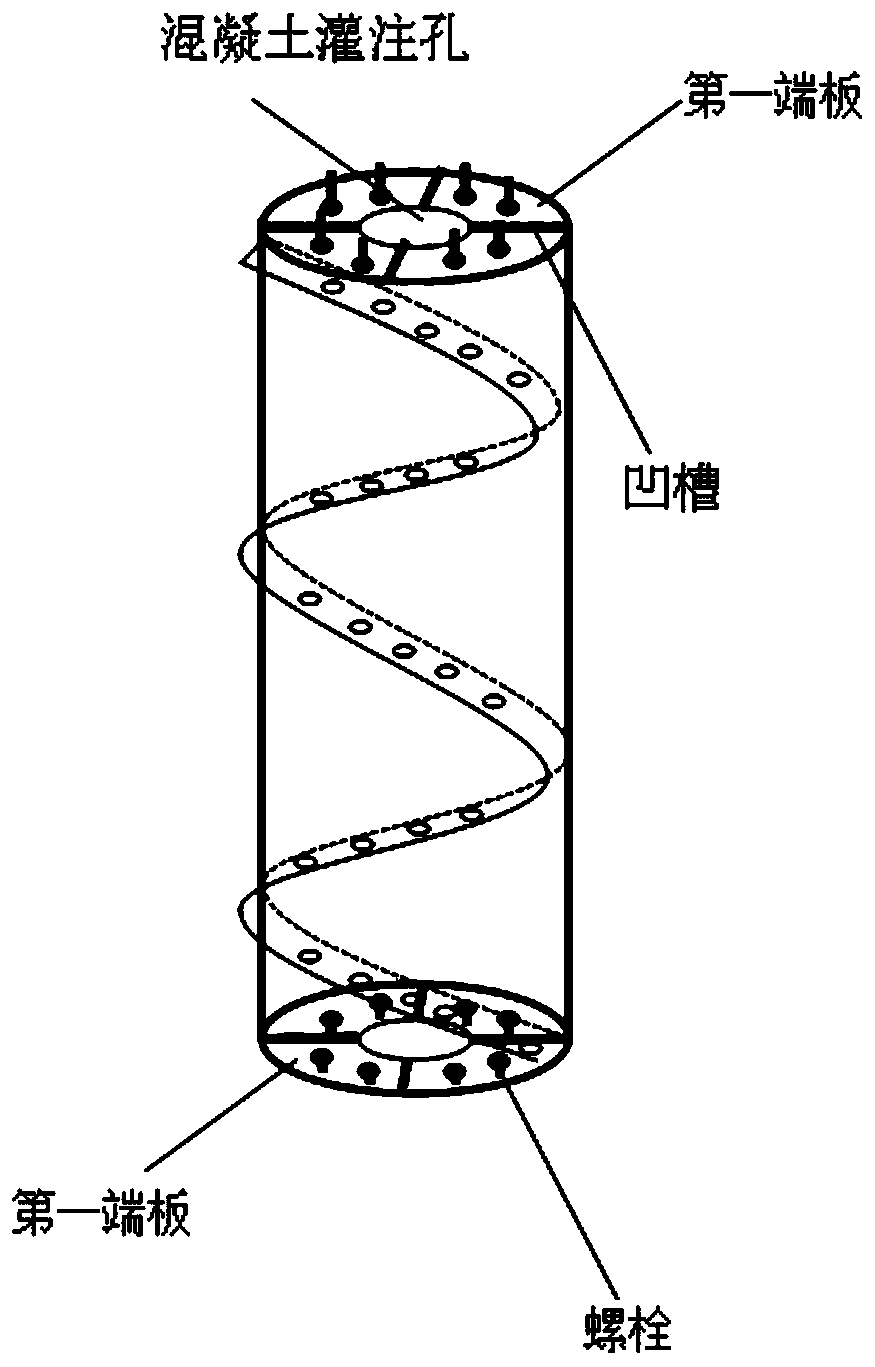

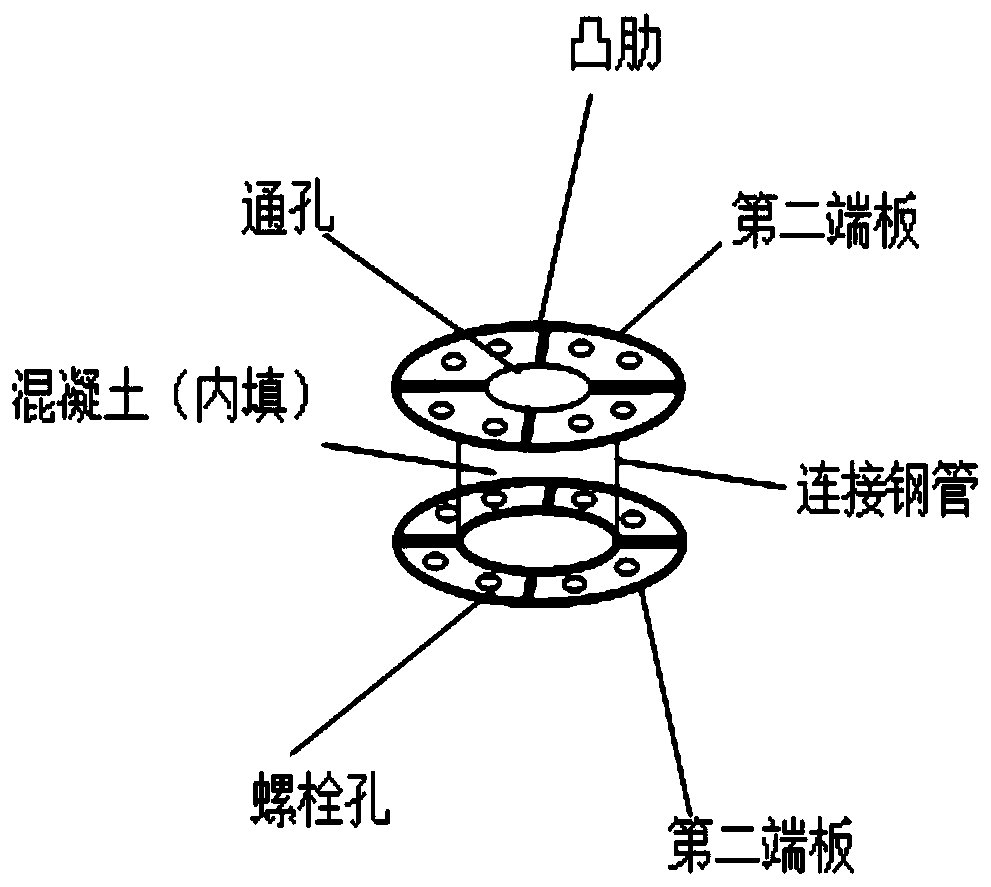

[0032] like figure 2 As shown, the two ends of the steel pipe are respectively fixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com