Socketed pile thread-like steel protecting cylinder capable of being drilled and using method thereof

A technology of steel casing and rock-socketed piles, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of lateral cracking, broken piles, adverse effects of rock-socketed pile construction quality and bearing performance, etc., to improve the bearing capacity , Improve the effect of pile side friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

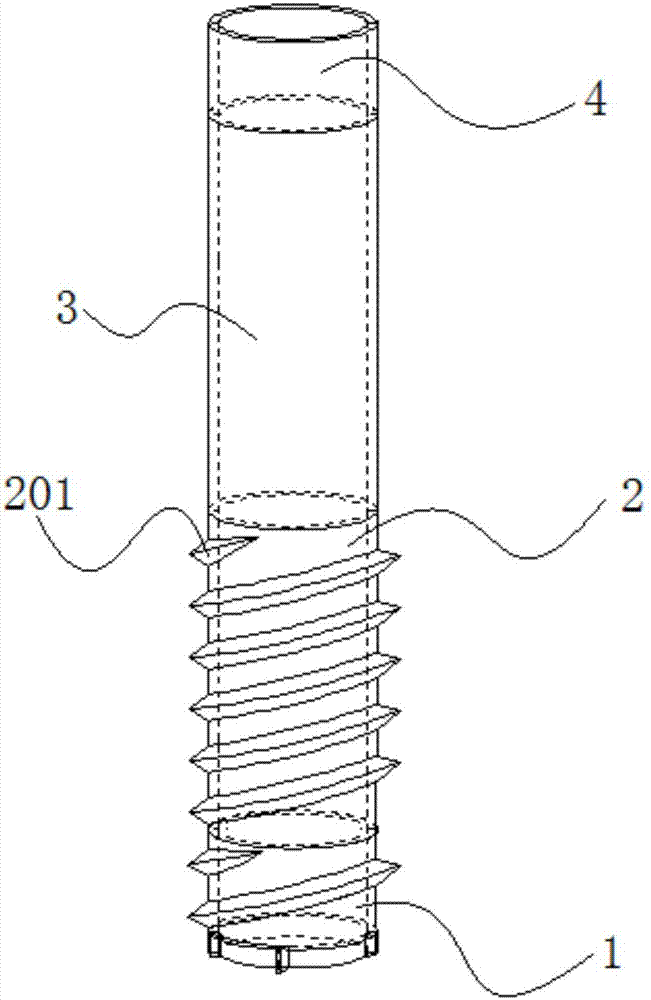

[0034] This embodiment discloses a threaded steel casing for drillable rock-socketed piles, comprising: an intermediate section 3, a driving section 4, a drill bit section 1 and a threaded section 2 that can be embedded in rock and soil.

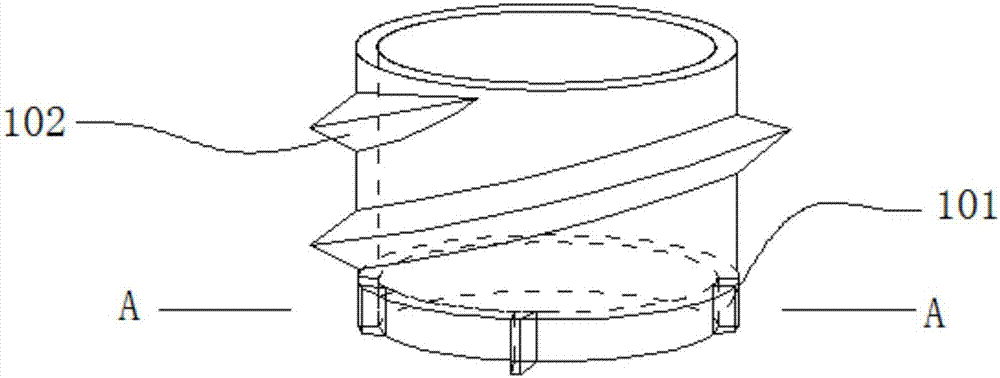

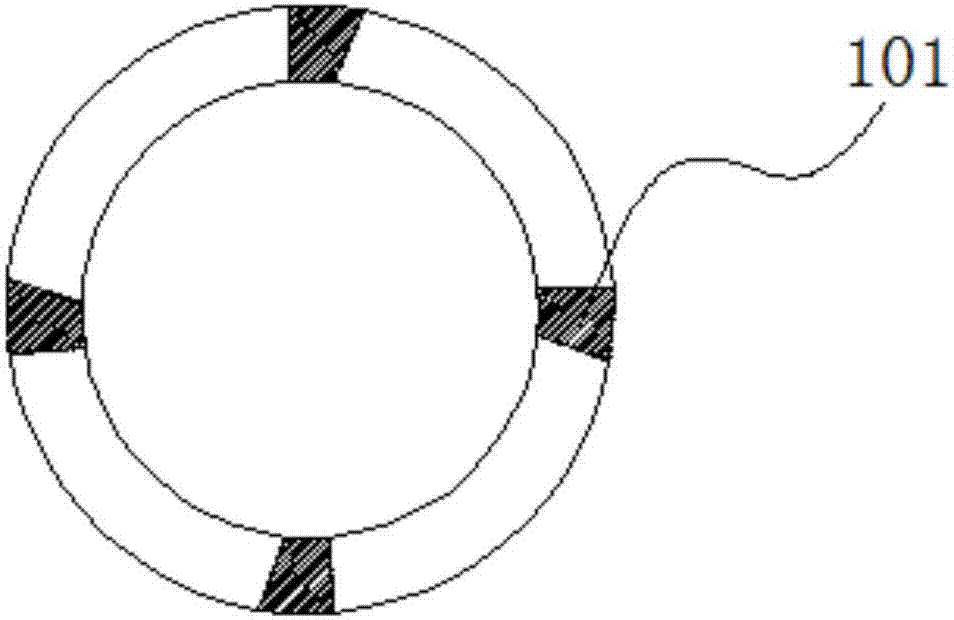

[0035] see figure 2 with image 3 , the drill bit segment 1 is a hollow cylinder with upper and lower ends open. Four high-strength alloy blocks 101 are arranged on the outer peripheral wall of the drill bit section 1 . The high-strength alloy block 101 is arranged in the lower section of the drill bit section 1 . The high-strength alloy blocks 101 are arranged obliquely and evenly distributed along the circumferential direction. The four high-strength alloy blocks 101 deflect in the same direction. The high-strength alloy block 101 is used to cut the foundation rock mass during drilling, and the oblique arrangement is conducive to the accumulation of rock debris generated during drilling in the pile hole. A helical blade I102 is also ...

Embodiment 2

[0041] This embodiment discloses a method for using the threaded steel casing of the above-mentioned drillable rock-socketed pile, which includes the following steps:

[0042] 1) Assemble the drill section 1, thread section 2, middle section 3 and drive section 4 together. Wherein, the middle section 3 and the driving section 4 can be detachable as required.

[0043] 2) Use the construction platform and hoisting equipment to vertically position the assembled steel casing at the pile position.

[0044] 3) To sink the steel casing, use the self-weight of the steel casing, and apply a vertical downward static or dynamic load on the top of the steel casing, or apply a vertical downward load and a rotational moment at the same time, so that the steel casing is vertical Drill down through the soil foundation and into the rock foundation to a certain depth.

[0045] 4) Use soil excavation and rock excavation equipment to excavate the foundation in the sunken steel casing and remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com