Partial prestressed concrete hollow triangular pile

A technology of concrete and triangular piles, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as low reinforcement ratio, integrity, and difficulty in meeting high requirements for shear, flexural, and tensile properties, and achieves successful results. The pile bearing capacity is large, the effect of increasing the construction pile rate and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

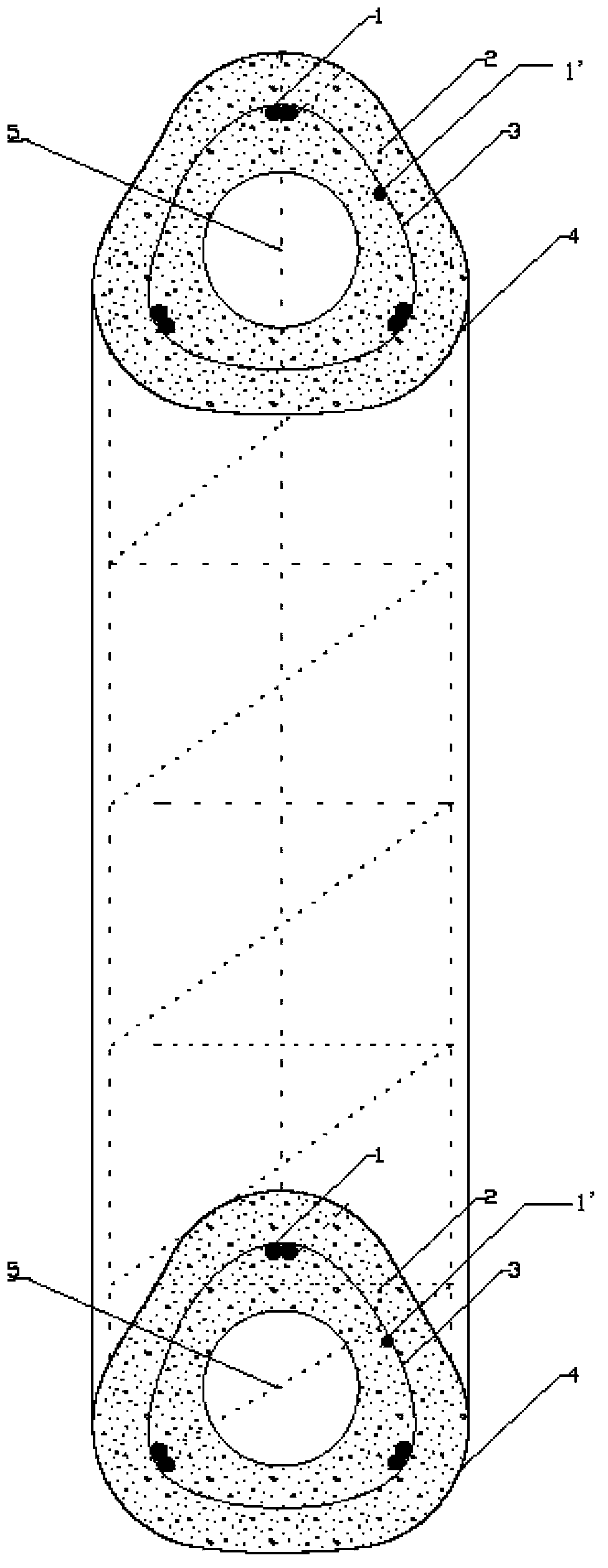

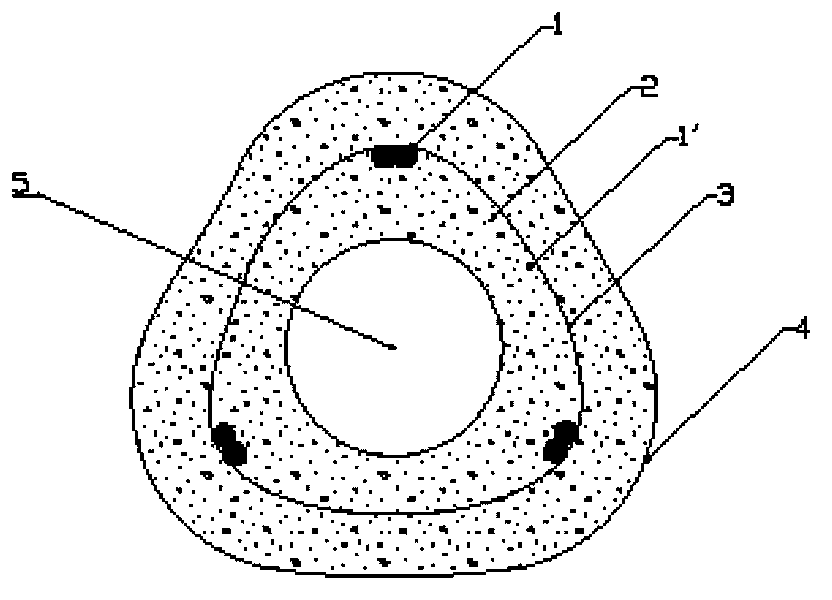

[0022] figure 1 is a perspective view of the present invention, figure 2 It is a sectional view of the present invention. Such as figure 1 and 2 Shown: a partially prestressed concrete hollow triangular pile, the longitudinal axis direction of the partially prestressed concrete hollow triangular pile is provided with a central through hole 5 that runs through the entire partially prestressed concrete hollow triangular pile, and the partially prestressed concrete hollow triangular pile The inner peripheral cross-section of the pile is circular, the outer peripheral cross-section of the part of the prestressed concrete hollow triangular pile is a rounded triangle 4, and the geometric dimensions of the inner and outer peripheral sections of the part of the prestressed concrete hollow tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com