Prefabricated pile with external hoops and filled with sand-gravel aggregates, and construction method thereof

A technology of prefabricated piles and sand and gravel materials, applied in sheet pile walls, foundation structure engineering, soil protection, etc., can solve the problems of differential settlement after pile foundation construction, slow foundation soil consolidation, etc., and accelerate the soil consolidation process , Improving the bearing capacity of pile foundation and the effect of increasing pile end resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and implementation steps. The technical features in the specific embodiments of the present invention can be combined with each other without conflict, which does not constitute a limitation.

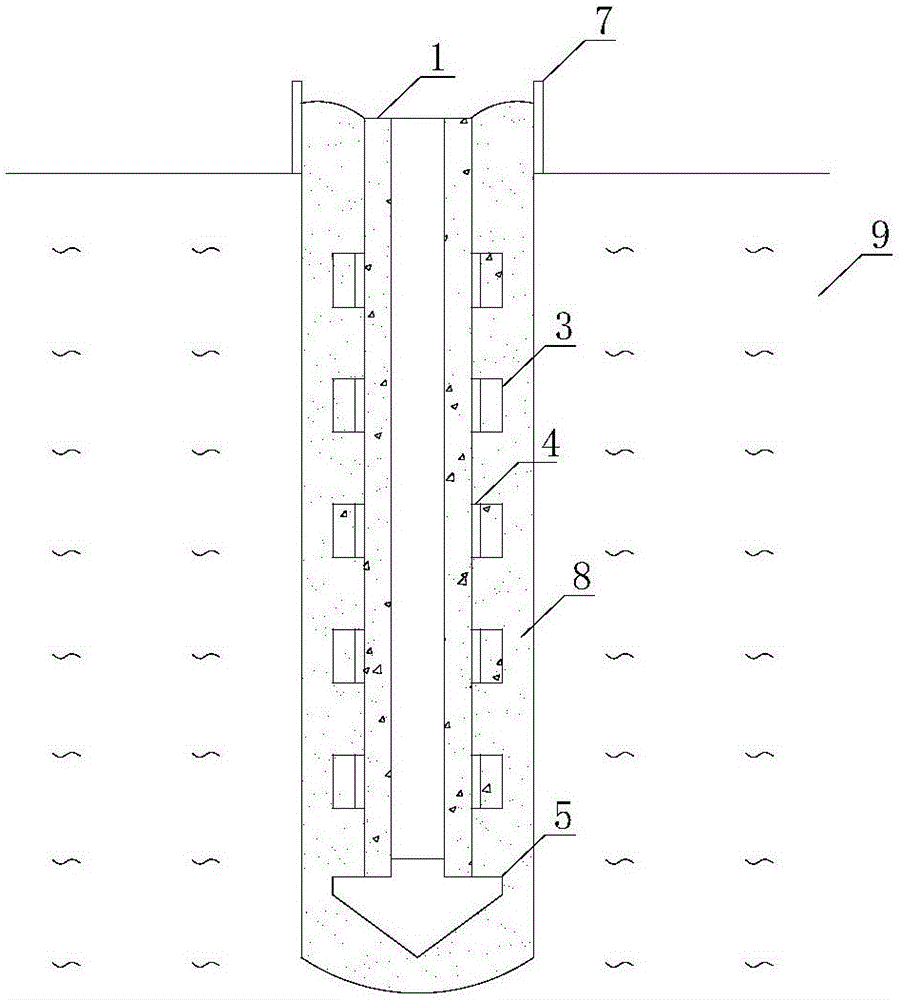

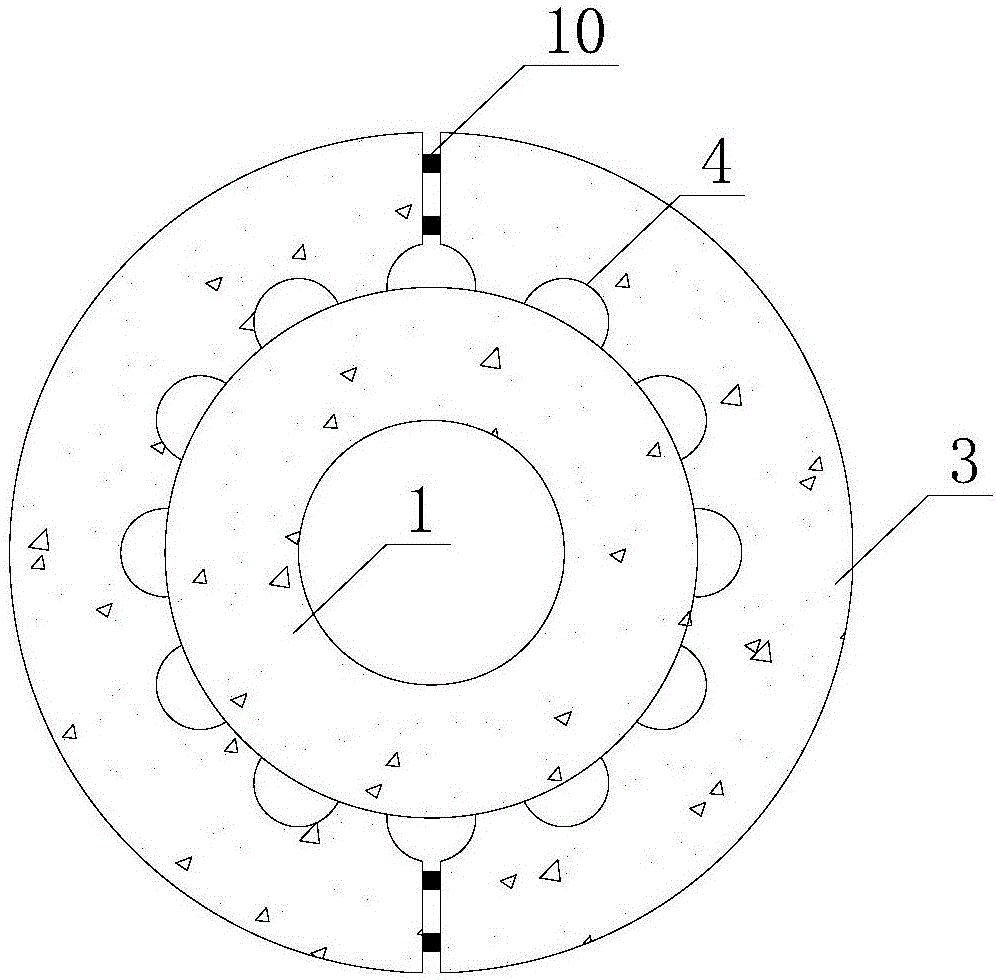

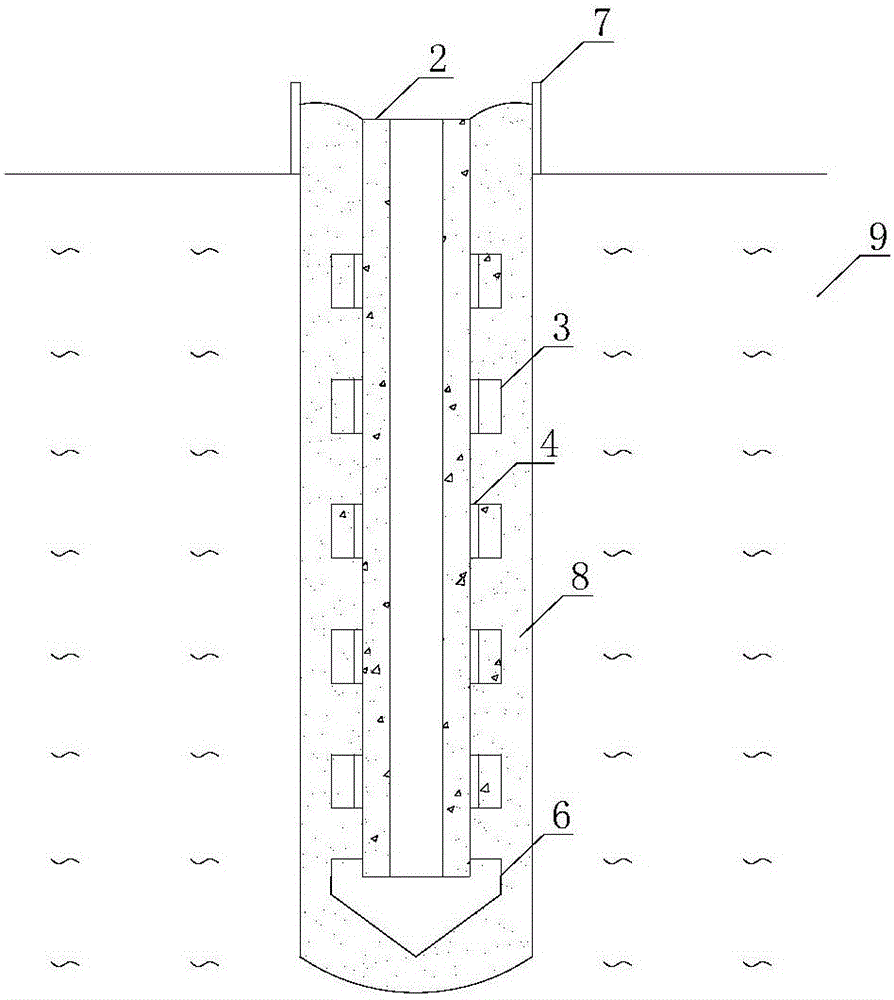

[0028] Such as figure 1 As shown, it is a schematic longitudinal sectional view of the prefabricated pile structure filled with sand and gravel with additional hoops in one embodiment. The prefabricated pile structure is buried in the foundation soil 9 to be treated, and is used to support superstructures or other structures. The prefabricated pile structure includes a prefabricated pipe pile body 1, a diameter-expanding collar 3 and an enlarged pile tip at the bottom of the pile. The cross-section of the prefabricated tubular pile body 1 is in the shape of a hollow ring, which can be prefabricated off-site and subsequently assembled on the construction site, or directly prefabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com