Bi-layer plastic-bushing inverted-arch cambered hollow special-shaped pile and construction method

A technology of plastic casing and anti-arched surface, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., to achieve the effect of improving pile quality, increasing pile side friction resistance, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The design and construction technical requirements of special-shaped reinforcement cages for pile bodies, the design and construction technical requirements of prefabricated pile tips, the design and construction technical requirements of pile concrete, steel cages, pile side cement soil, and the bonding of plastic casing and casing joints Construction technical requirements, etc., will not be repeated in this embodiment, and the embodiment of the structure involved in the present invention will be focused on.

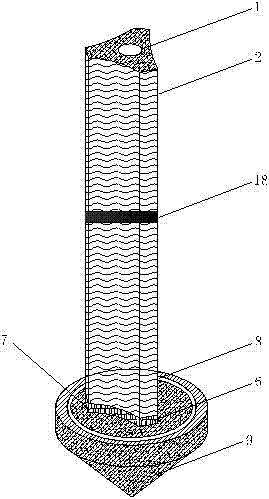

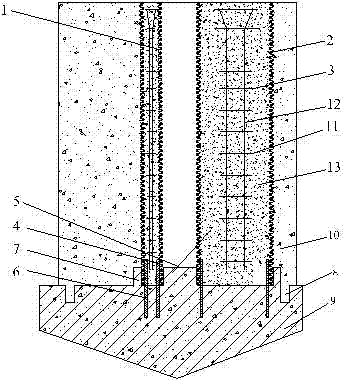

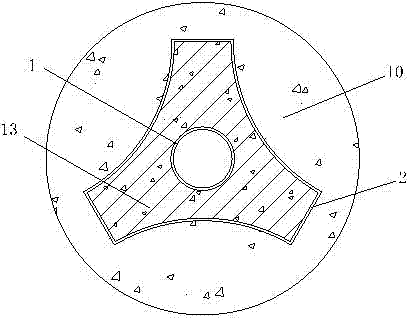

[0043] figure 1 It is a combined perspective view of a hollow special-shaped pile with a double-layer plastic casing and an anti-arch curved surface; figure 2 It is a cross-sectional view of a hollow special-shaped pile with a double-layer plastic casing and an anti-arch curved surface of the present invention, image 3 It is a cross-sectional view of a hollow special-shaped pile with a double-layer plastic casing and an anti-arch curved surface.

[0044] ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com