Lightweight high-strength pavement equipment

A kind of equipment and high-strength technology, applied in the field of lightweight and high-strength pavement equipment, can solve the problems of poor wear resistance and anti-skid performance, slow speed, large weight and volume, etc., to meet the needs of maneuvering, avoid damage, and enhance the effect of lateral rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

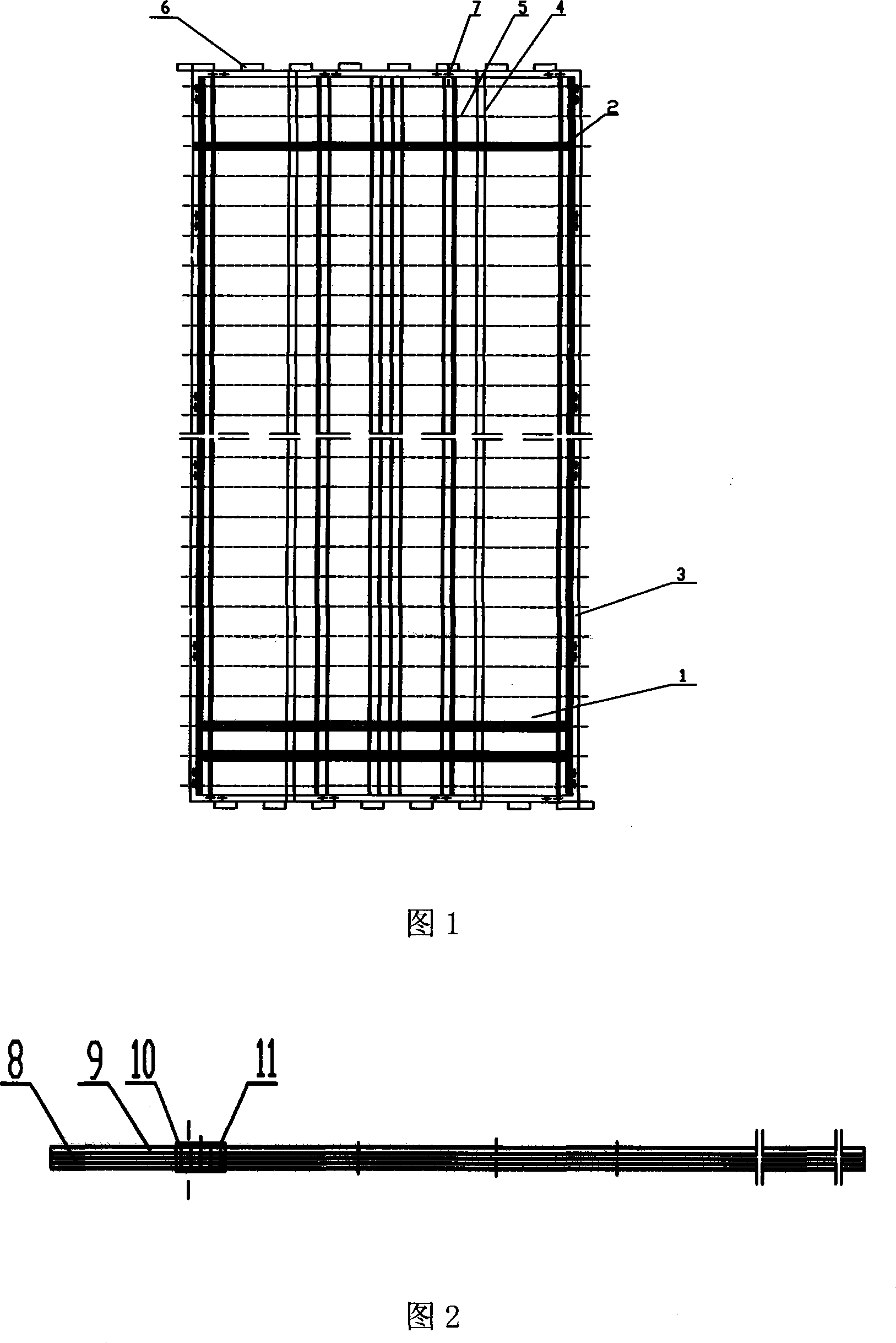

[0030] A light-weight, high-strength wear-resistant and non-slip pavement equipment mainly consists of a pavement substrate, a support rod, a joint device and a mooring device. In this embodiment, the length of a single section of road is 15.2m, and the effective width is 4.02m. The carbon fiber joint rod between the two sections of road can be quickly spliced and disassembled.

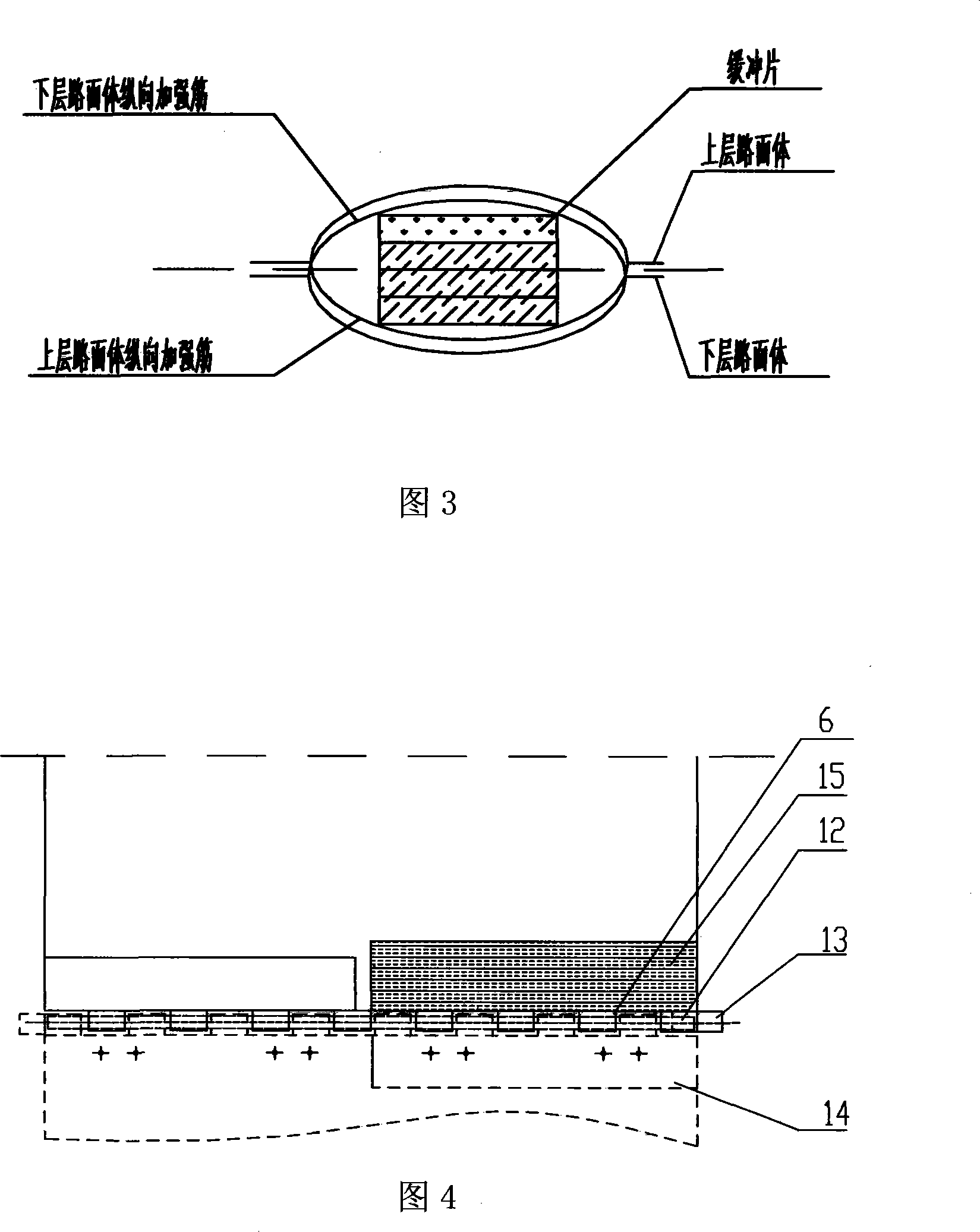

[0031] The pavement matrix is the main carrier of the pavement, which is used to provide the anti-fracture and anti-penetration capabilities of the pavement, and improve the road traffic capacity of vehicles. As shown in Figure 1, the pavement matrix is mainly composed of double-layer fabric 1, belt channel 2, edge tape 3, radial reinforcement 4 and transverse restraint belt 5, etc. The double-layer fabric 1 is mainly formed by composite braiding of ultra-high-strength polyethylene filaments and polyester industrial filaments. In the weft direction of the double-layer fabric 1, there is a belt-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com