motorcycle tires

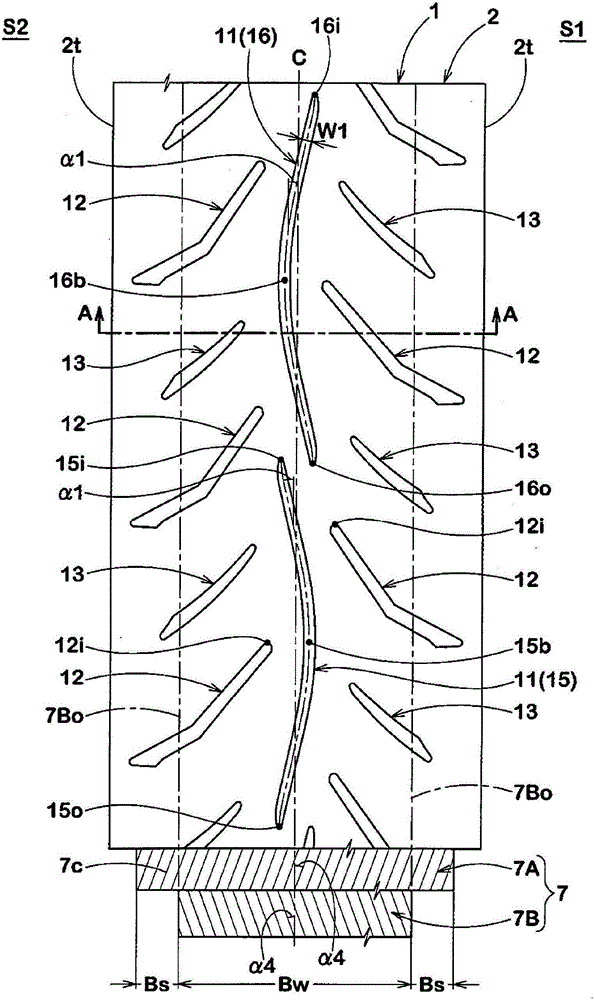

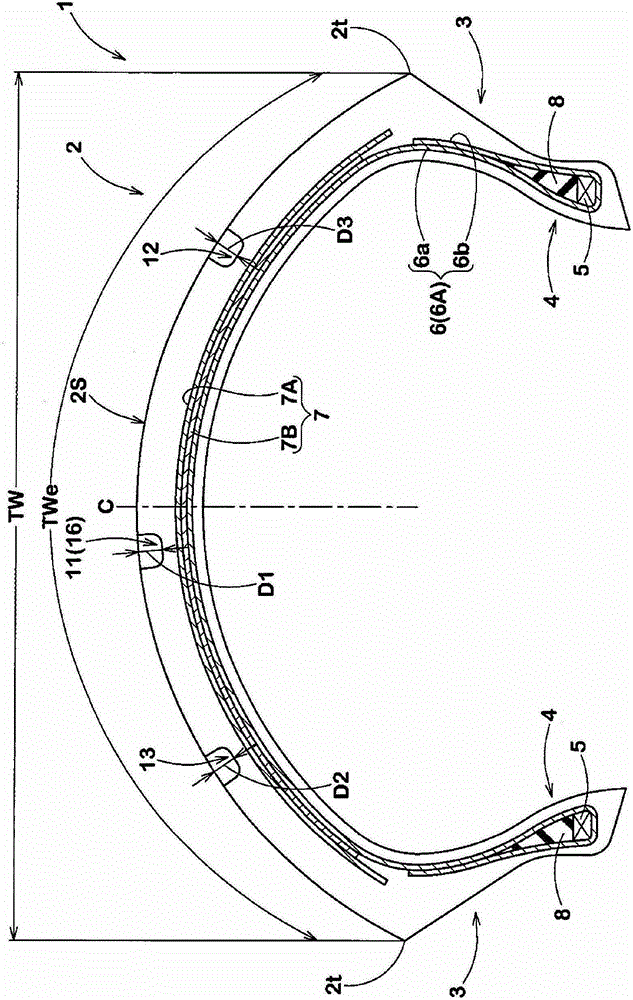

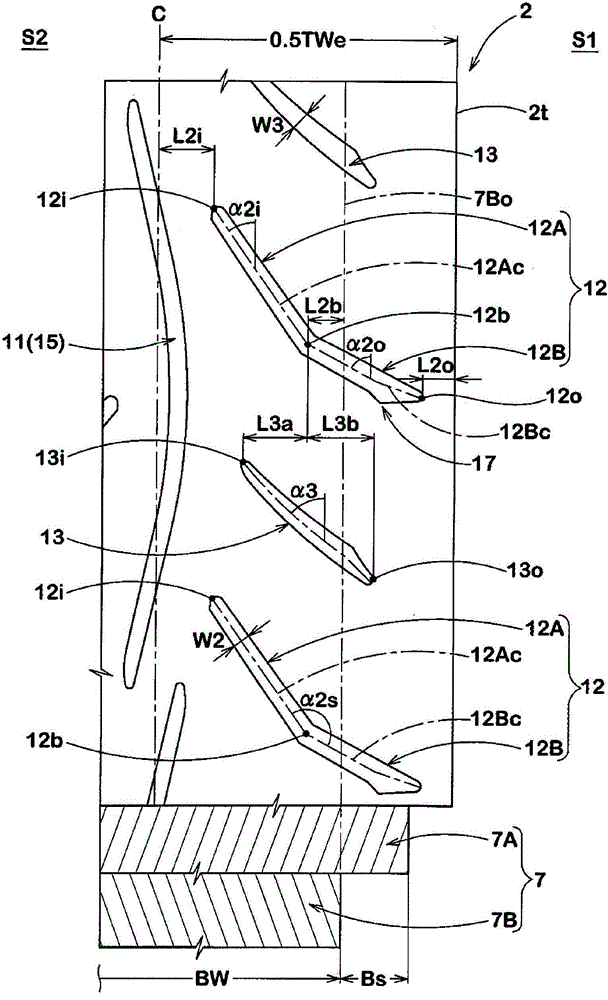

一种摩托车、轮胎的技术,应用在摩托车轮胎、摩托车、轮胎零部件等方向,能够解决操作转向盘重量的变化(过渡特性变差等问题,达到提高排水性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] Manufacturing has figure 2 The basic structure of motorcycle tires having main inclined grooves and auxiliary inclined grooves according to the specifications in Table 1, and their performances were tested. Furthermore, in order to compare Figure 4 The same test was carried out on the tire shown without a kink (Comparative Example 1). Among them, the common specifications are as follows.

[0065] Tire size:

[0066] Front wheel: 120 / 70ZR17

[0067] Rear wheel: 160 / 60ZR17

[0068] Rim size:

[0069] Front wheel: MT3.50×17

[0070] Rear wheel: MT4.50×17

[0071] Tread half unfolded width 0.5TWe: 83mm

[0072] Longitudinal main groove:

[0073] Groove width W1: 4.7mm, groove depth D1: 4.1mm

[0074] Main inclined groove:

[0075] Groove width W2: 5.4mm, groove depth D2: 4.1mm

[0076] Auxiliary inclined groove:

[0077] Groove width W3: 5.3mm, groove depth D3: 3.5mm

[0078] The test method is as follows.

[0079]

[0080] The rims of each test tire were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com