Patents

Literature

33results about How to "High long-term strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

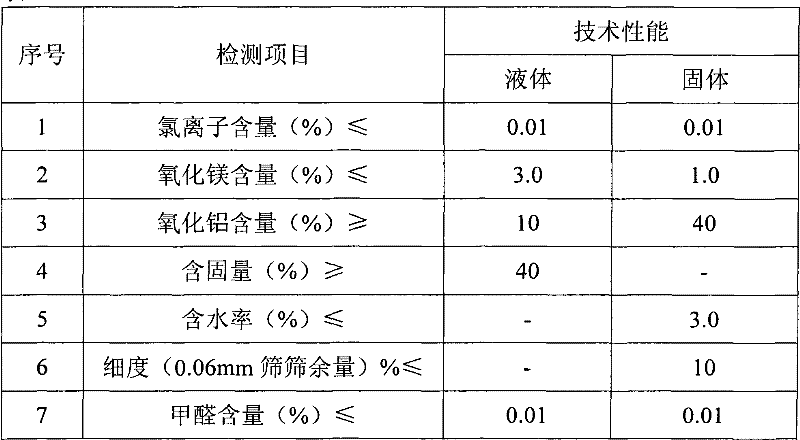

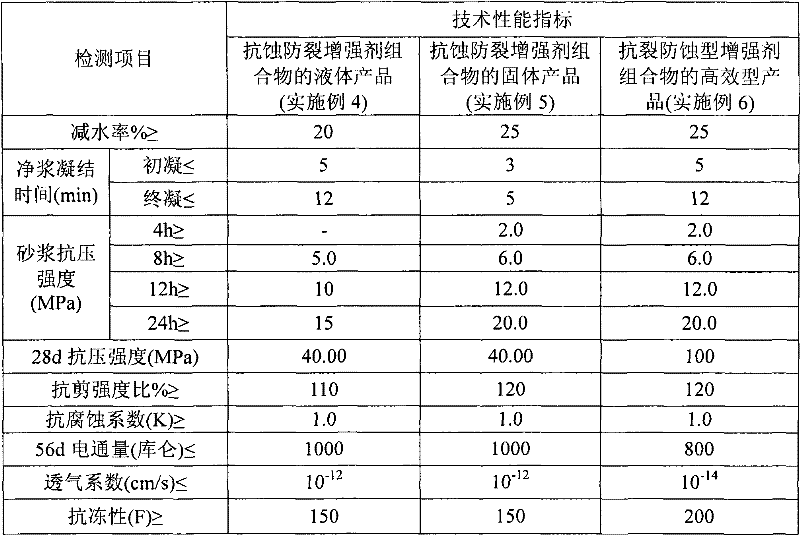

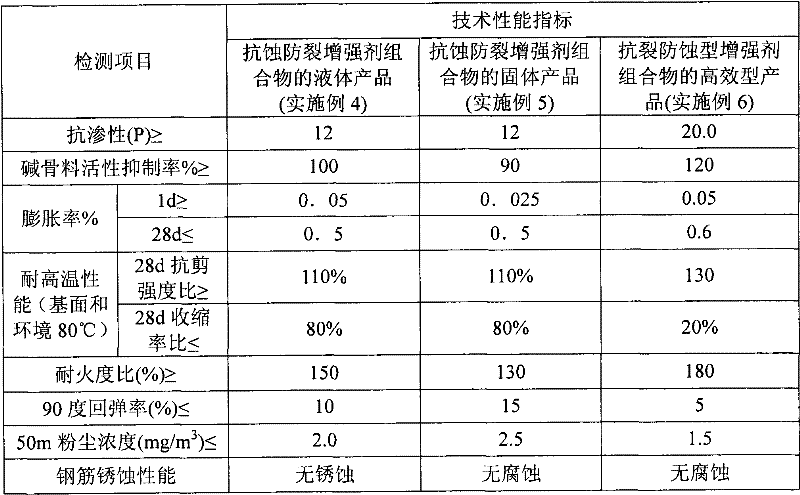

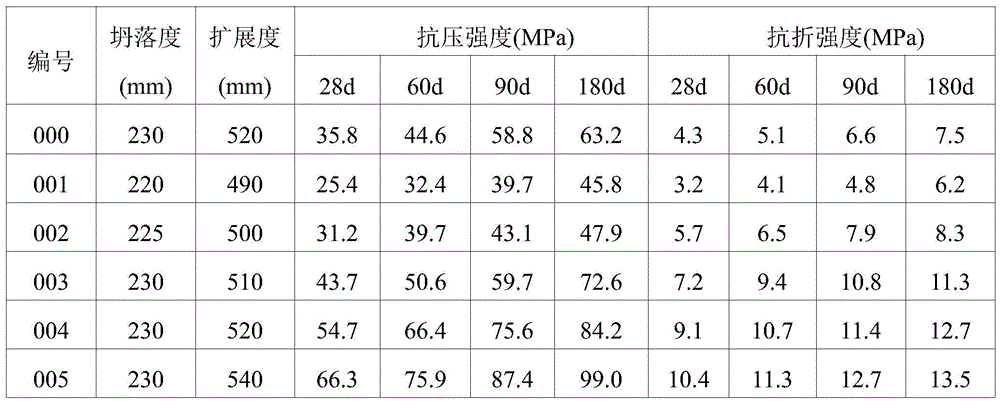

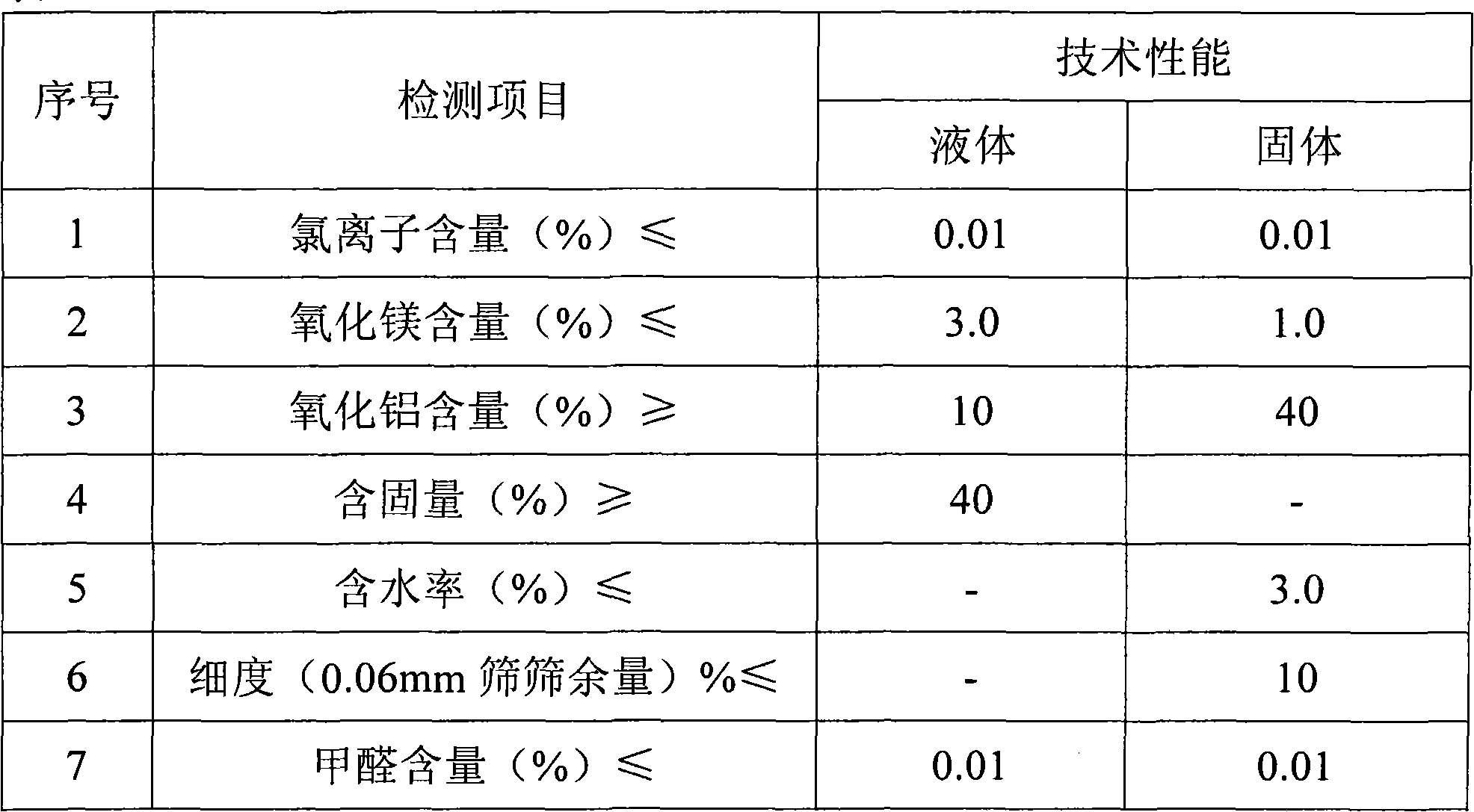

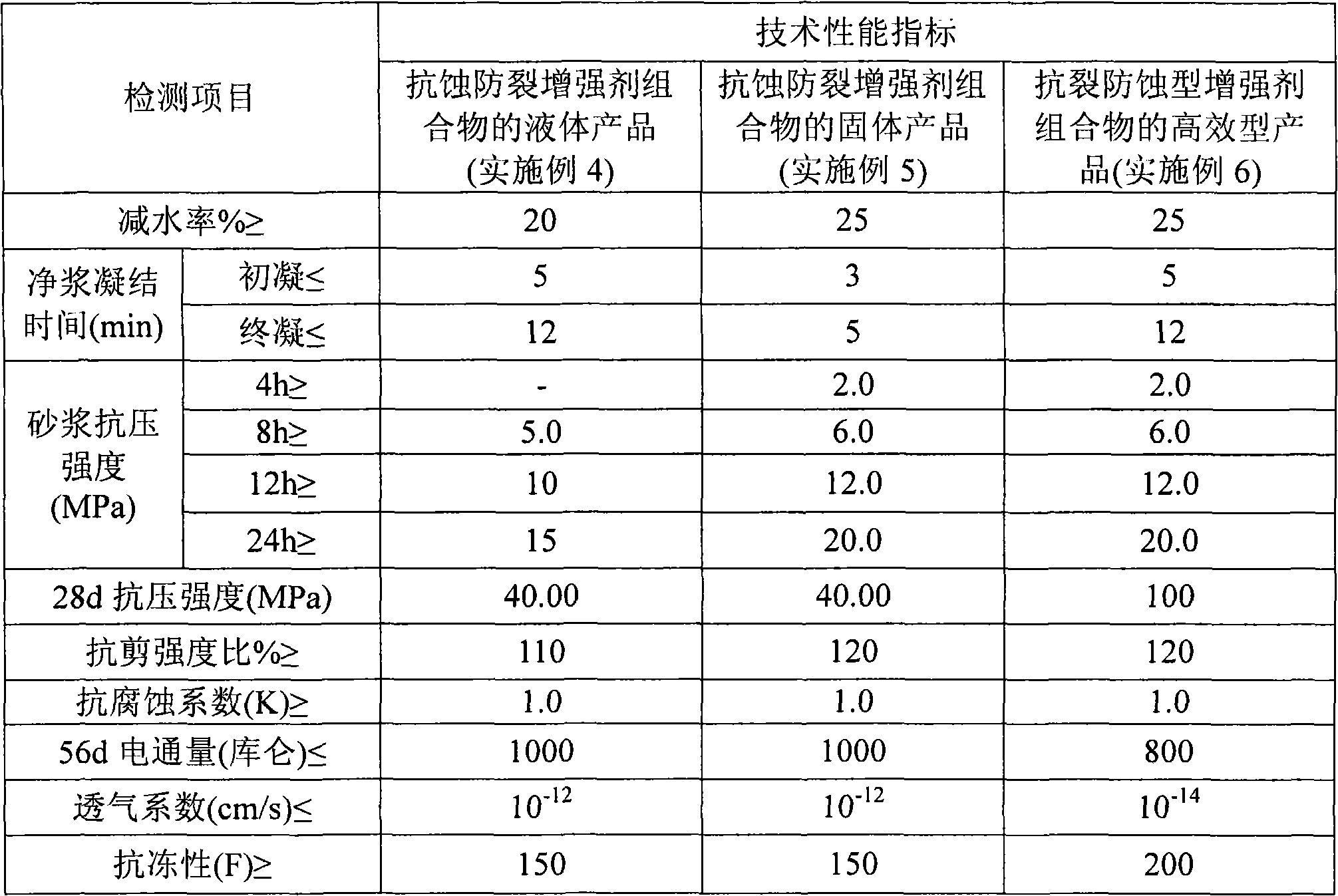

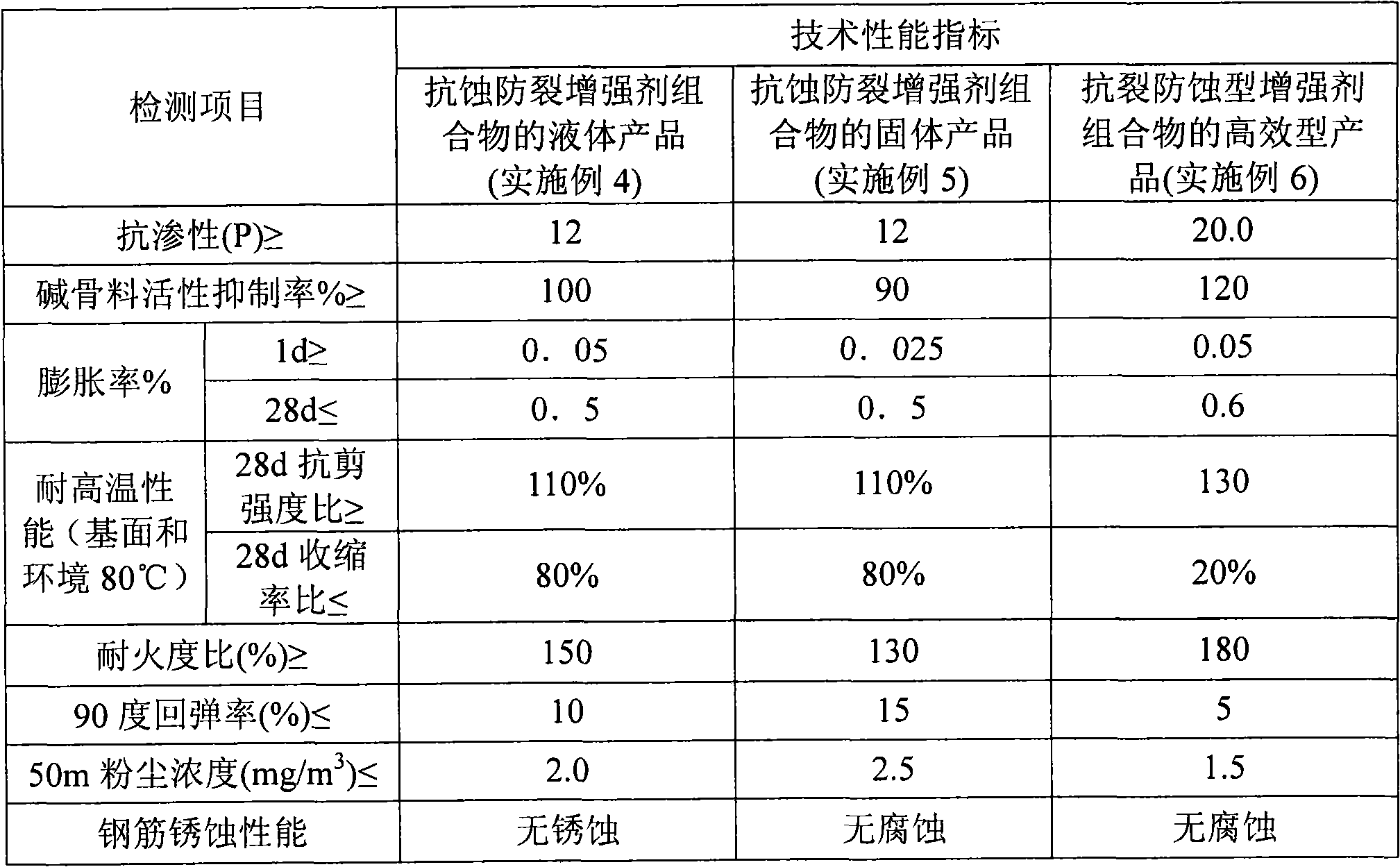

Anti-corrosion anti-cracking reinforcing agent composition and preparation method thereof

The invention relates to an anti-corrosion anti-cracking reinforcing agent composition for concrete, mortar, and net slurry used in injection (first-aid repair) engineering, and a preparation method thereof. The composition comprises the following components on a percentage basis: 2-50% of micro-expansive powder, 5-30% of reinforcing powder, 5-20% of anti-corrosion compacting agents, 10-20% of plasticizers, 1-6% of catalysts, and 10-60% of carriers. The composition of the invention prepares solid and liquid products by processes of melting refinement, polymerization, ball milling, jet milling, complex formulation, and the like, and thus meets construction process requirements of different first-aid repair endurance engineering.

Owner:四川巨星新型材料有限公司

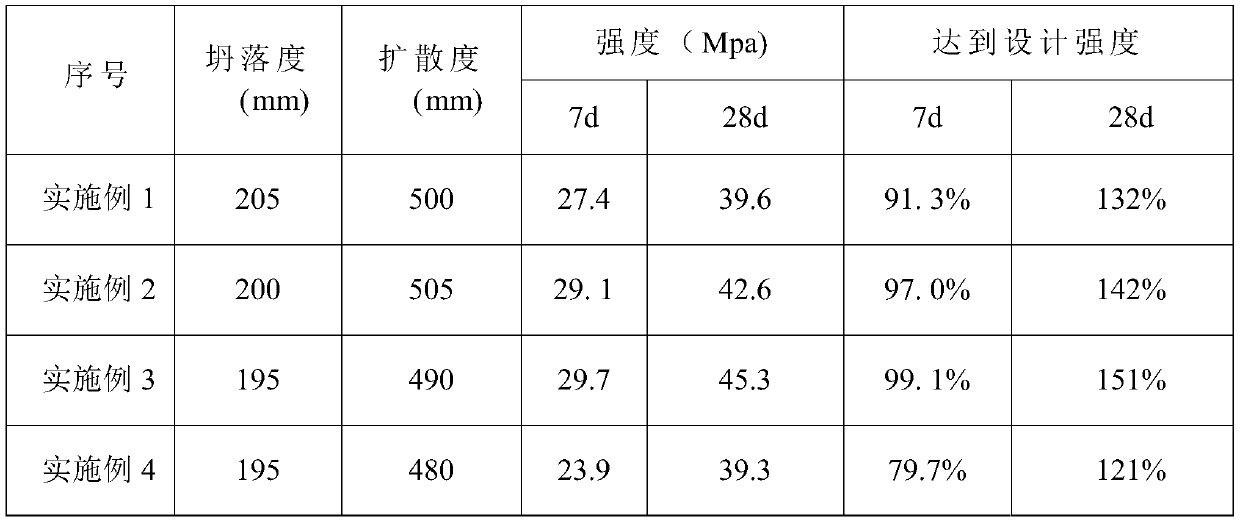

High-performance concrete with large mixing amount of mineral powder and manufacturing method of high-performance concrete

The invention discloses high-performance concrete with a large mixing amount of mineral powder and a manufacturing method of the high-performance concrete. The high-performance concrete is manufactured from cement, slag powder, coal ash, crushed stone, river sand, water, an exciting agent, and a water reducer, and comprises, by weight part: 140-170 parts of cement, 170-240 parts of slag powder, 50-100 parts of coal ash, 1010-1100 parts of crushed stone, 735-825 parts of river sand, 150-180 parts of water, 11-15 parts of an exciting agent, and 3.4-5 parts of a water reducer. Slag powder and coal ash are re-mixed into the concrete as a supplementary cementitious material, through an exciting effect of the sodium sulfate exciting agent, to manufacture the high-performance concrete with a large mixing amount of mineral powder. Long-term strength, durability, and working performance of the cement concrete are effectively improved. A large amount of industrial waste, such as mineral powder and coal ash, is utilized in the formula, thereby reducing cement consumption in pre-mixed concrete. The cost is reduced, and the method is energy-saving and eco-friendly.

Owner:武汉武新新型建材股份有限公司

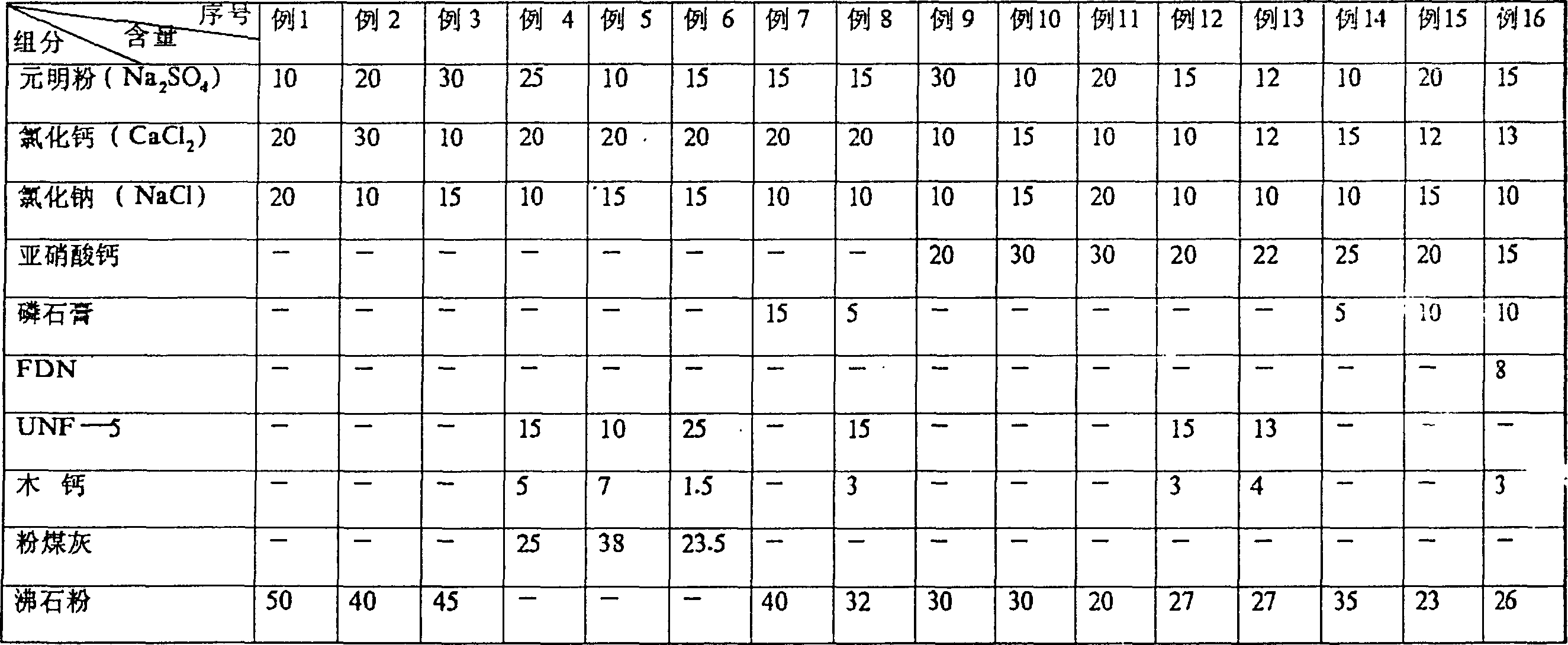

Flyash excitant

The flyash excitant has two different compositions. That for no-steel bar concrete consists of mirabilite 10-30 wt%, calcium chloride 10-30 wt%, sodium chloride 10-20 wt%, efficient water reducing agent 10-25 wt%, calcium lignosulfonate 1.5-7.0 wt% and ardealite 5-15 wt% other than carrier material. That for reinforced concrete consists of mirabilite 10-30 wt%, calcium chloride 10-15 wt%, sodium chloride 10-20 wt%, calcium nitrite 20-30 wt% efficient water reducing agent 6-10 wt%, calcium lignosulfonate 2-5 wt% and ardealite 5-15 wt% other than carrier material. The flyash excitant can excite the latent activity of flyash effectively so as to increase the added amount of flyash in concrete and lower the cost of concrete product.

Owner:葫芦岛市辽西混凝土外加剂有限公司

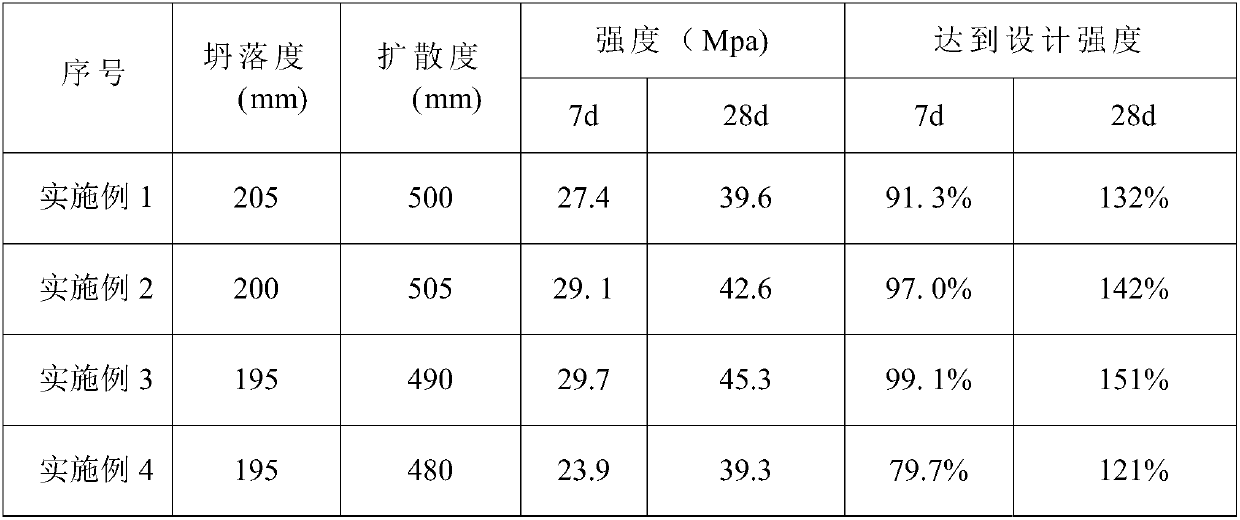

Large-dosage fly ash concrete and preparation method thereof

ActiveCN107602023AOvercome the defect of low early strengthHigh strengthCalcium hydroxideSodium Bentonite

The invention provides large-dosage fly ash concrete and a preparation method thereof. The large-dosage fly ash concrete is prepared from the following raw materials: cement, fly ash, mineral powder,gravel, river sand, water, a modified reinforcing agent and a polycarboxylate superplasticizer, wherein the modified reinforcing agent is prepared from bentonite, attapulgite, lignosulfonate, sodium sulfate, calcium hydroxide, triethanolamine maleate and water. The preparation method comprises the following steps: adding the cement, the mineral powder, the fly ash, the modified reinforcing agent,the gravel and the river sand into a mixer; performing dry mixing for 30-40min; adding the water and the superplasticizer into the mixer; mixing for 10-15min to obtain the large-dosage fly ash concrete. According to the large-dosage fly ash concrete and the preparation method thereof provided by the invention, a multifunctional modified synergistic for large-dosage fly ash concrete is prepared from the roasted bentonite together with attapulgite, organic and inorganic activators and a surfactant; by combining the multifunctional modified synergistic with an early-strength polycarboxylate superplasticizer, the aim of improving the strength, compactness and durability of the large-dosage fly ash concrete can be achieved.

Owner:南京平达绿色建材科技有限公司

Silica sol slow infiltration reinforcing method of argillaceous soft rock

ActiveCN105201528ASolve the problem of physical expansionImprove compactnessUnderground chambersTunnel liningMicrostructureMaterials science

The invention discloses a silica sol slow infiltration reinforcing method of argillaceous soft rock, which belongs to the silica sol slow infiltration reinforcing method of the argillaceous soft rock. The silica sol slow infiltration reinforcing method is realized by the following steps of a, evaluating lithological changes, pore development characteristics and hydrogeological conditions of roadway surrounding rock, and determining grouting hole parameters and silica sol mixture ratio; b, constructing grouting holes before argillization; mounting a grouting pipe and sealing the holes, and injecting silica sol; during operation, quickly filling and reinforcing macrofractures with the silica sol under the drive of grouting pressure; c, when the grouting pressure is reduced to a certain value, maintaining low pressure for a long time; during operation, enabling the silica sol to slowly diffuse and enter into microfissures of a rock mass under the drive of a capillary force to form a high-compactness reinforcing body, and finishing the reinforcing of the surrounding rock. According to the silica sol slow infiltration reinforcing method disclosed by the invention, the macrofractures are filled, water microchannels of molecules and air molecules in a mud rock matrix are closed, microcosmic effects such as adsorbing, dissolving and weathering are obviously hindered, the compactness and the integrity of a microstructure of mud rock are greatly improved, and further the permeability is reduced, and eventually the deformation resistance and the durability of the rock mass are improved.

Owner:CHINA UNIV OF MINING & TECH

High-strength muck unfired product and preparation method thereof

The invention discloses a high-strength muck unfired product and a preparation method thereof. The high-strength muck unfired product is prepared from the components in parts by weight: 20-50 parts ofblast furnace slag, 50-90 parts of muck, and 8-30 parts of an alkali-activator. According to the high-strength muck unfired product, the surface of the muck is coated with the blast furnace slag, calcium ions are released in an alkaline solution, the calcium ions substitute low-valence positive ions adsorbed on the surface of clay particles in the muck, the thicknesses of double electric layers on the surfaces of the clay particles are decreased, the distance between the particles become small, compaction is conducted under the action of the external pressure, and a more compact structure isobtained; active components in the blast furnace slag reacts with the alkali-activator to generate gelling substances such as C-A-S-H, the gelling substances are connected with muck particles, the early strength is formed, and sun cracking caused by water losing of the muck can be resisted; and under the high-alkaline condition, silicon oxide and aluminum oxide in the muck are released slowly to react with the alkali-activator in a pore solution, a geopolymer is generated, on the one hand, pores are filled, on the other hand, the muck particles are cemented better, and thus the long-term strength of the product is improved.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

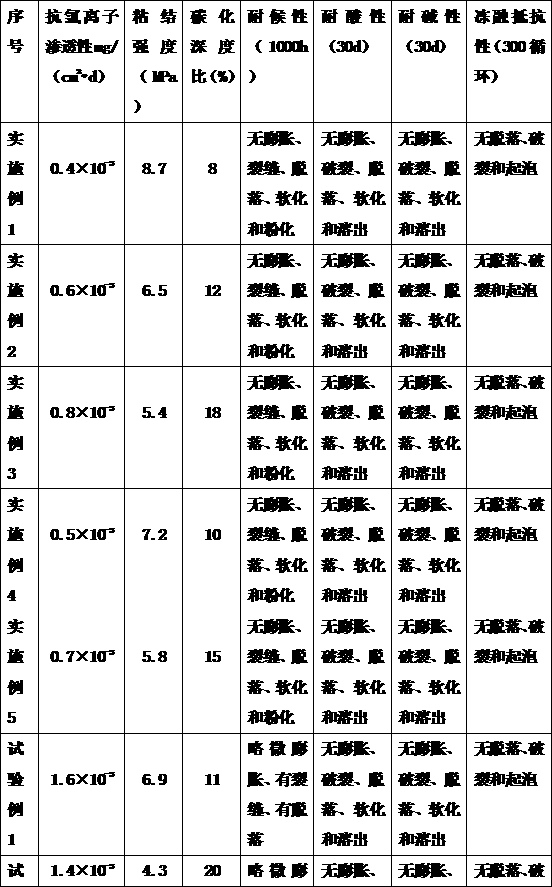

Preparation method and application of phosphorus-magnesium-based cement concrete coating protective material

The invention relates to the technical field of anticorrosive coating materials, in particular to a phosphorus-magnesium-based cement concrete coating protective material as well as a preparation method and the application thereof. The phosphorus-magnesium-based cement concrete coating protective material provided in the invention is prepared from the following raw materials in parts by weight, 55-90 parts of magnetite, 25-50 parts of a salt-resistant compacting agent, 20-35 parts of a mineral admixture, 0.5-2 parts of a high-efficiency water reducing agent, 5-15 parts of a composite retarder,10-25 parts of ground phosphate, 45-100 parts of quartz sand, 1-4 parts of fibers, 0.5-3 parts of a water-resistant agent and 2-5 parts of an alkaline pH stabilizer. The invention further provides apreparation method and application of the phosphorus-magnesium-based cement concrete coating protective material. The obtained phosphorus-magnesium-based cement concrete coating protective material has the advantages of being high in chloride ion permeability resistance, good in water resistance, good in gas resistance, high in durability, high in adhesive force with a base material, good in crackfollowing performance, resistant to corrosion, salt mist, alkali and aging, low in cost, environmentally friendly, simple in process and the like, and has good practical application value.

Owner:山东坊能新动能科学研究院有限公司

High-speed railway active powder concrete prefabricated component and preparation method thereof

The invention belongs to the technical field of concrete construction, and particularly relates to a high-speed railway active powder concrete prefabricated component and a preparation method thereof.The high-speed railway active powder concrete prefabricated component is prepared from the following raw materials: cement, silicon powder, coal ash, quartz sand, water, a water reduction agent and steel fibers. By utilizing the high strength, high durability, high toughness and high stability of RPC for producing relevant concrete component products in the field of high-speed railway, the service life of the component can be effectively prolonged, the maintenance expense can be greatly reduced, and the comprehensive expense of the engineering construction and application can be reduced.

Owner:RUZHOU ZHENGTIE SANJIA CEMENT PROD

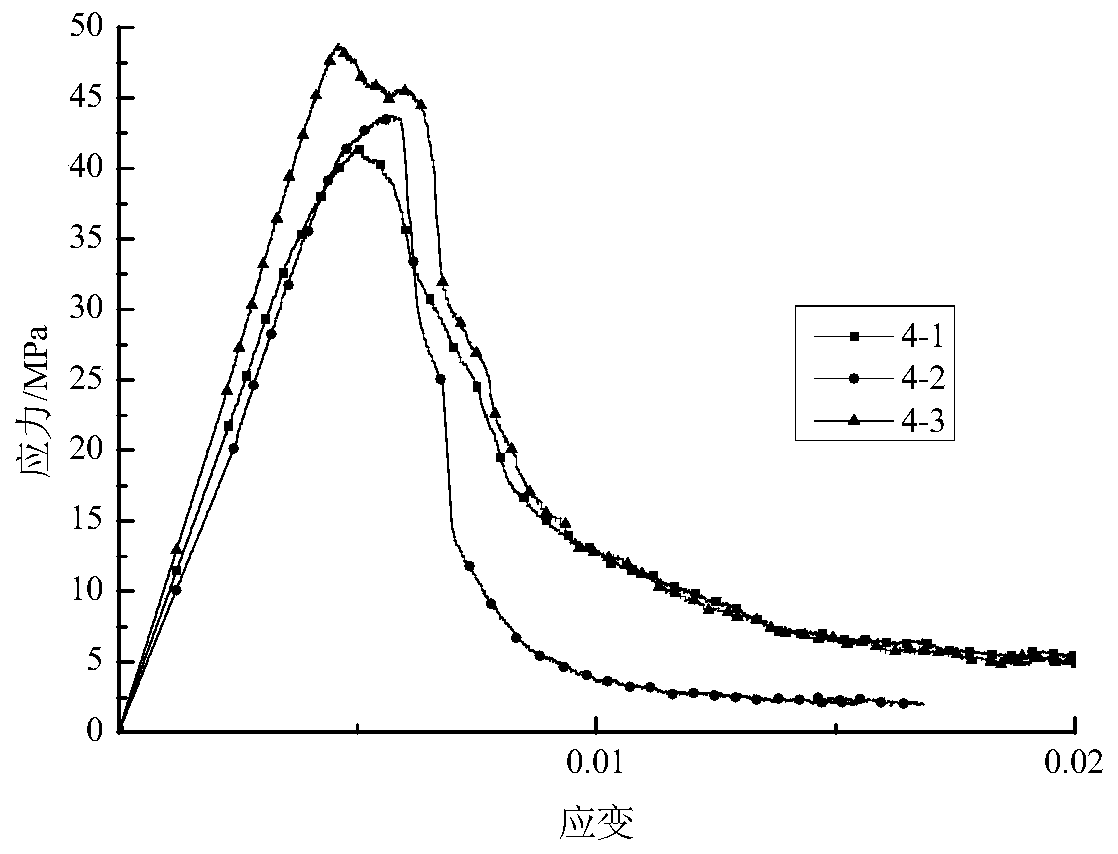

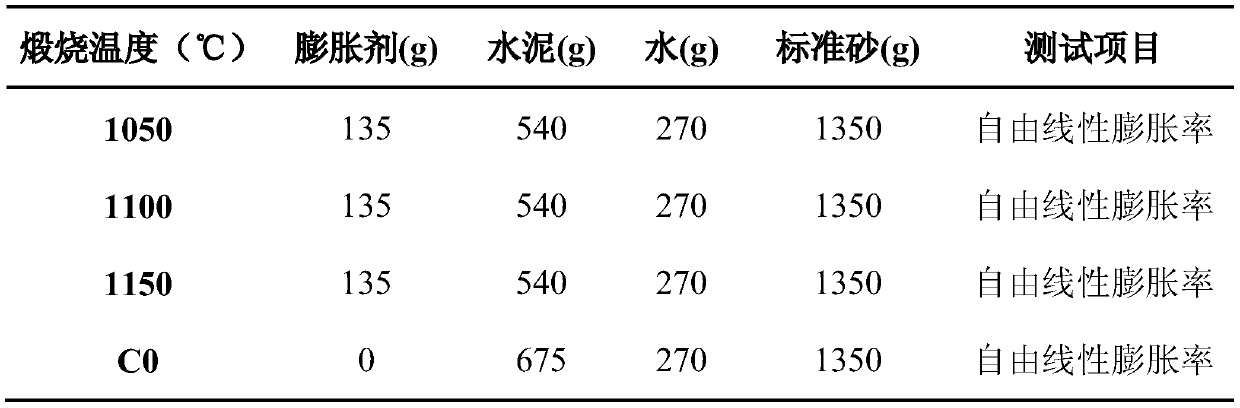

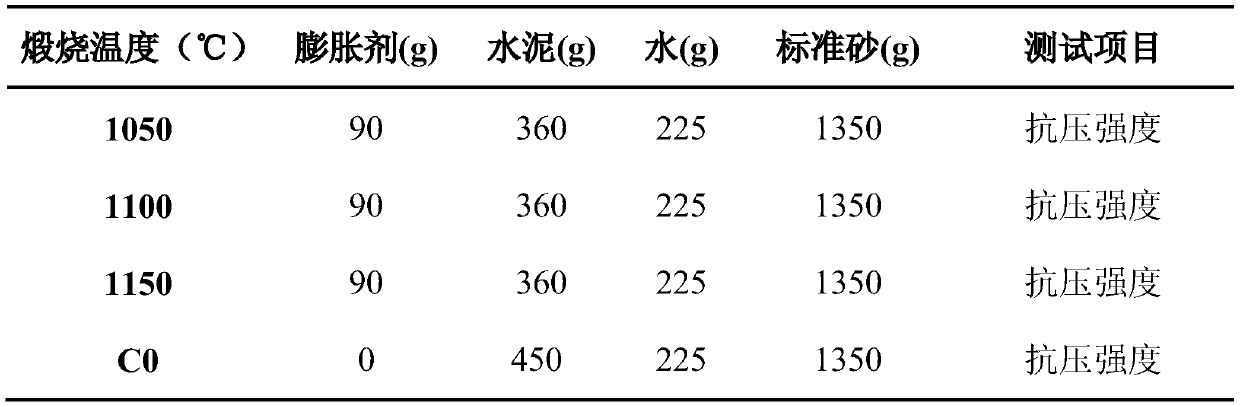

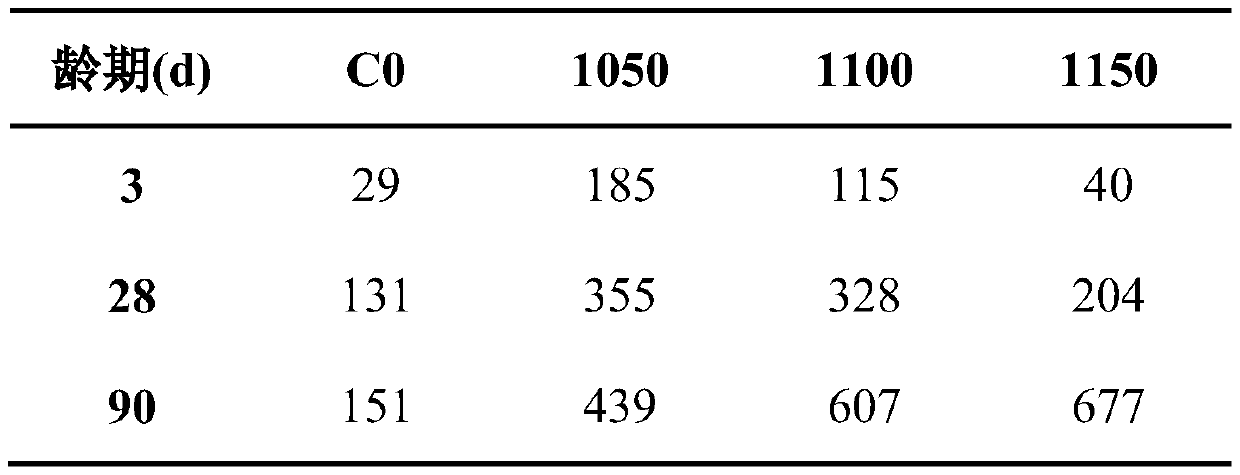

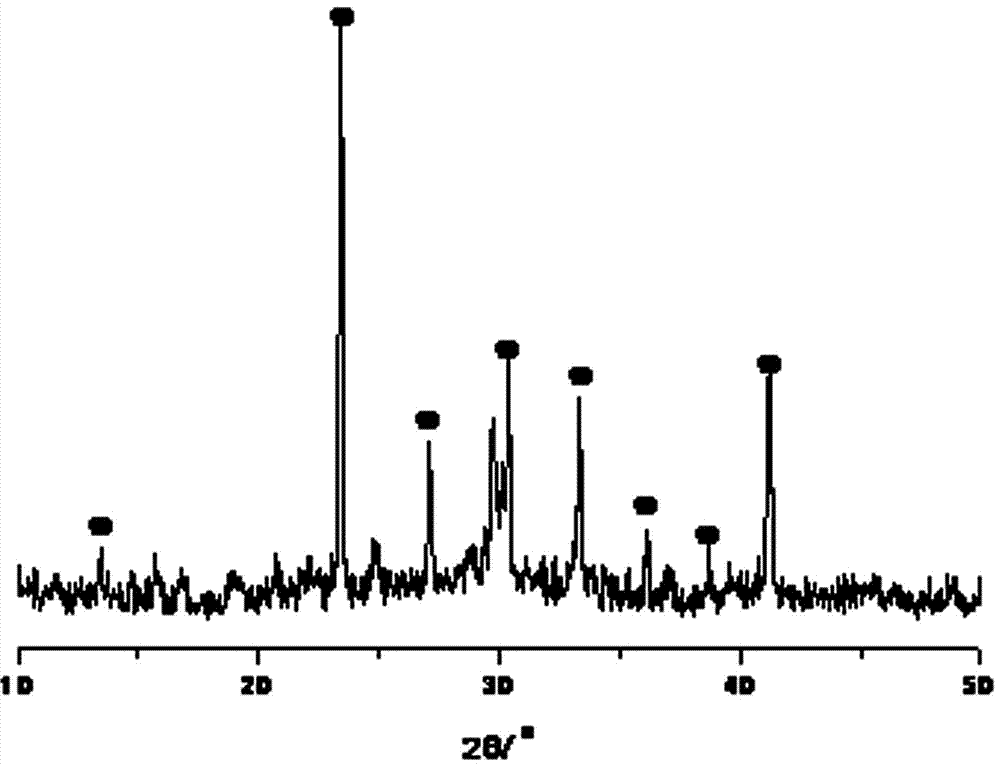

Preparation method and application of composite magnesium oxide expanding agent

The invention discloses a preparation method and application of a composite magnesium oxide expanding agent, and belongs to the technical field of preparation of concrete special functional materials.The preparation method specifically comprises the following step: calcining a dolomite and serpentine mixture with a specific ratio at the temperature of 1050-1150 DEG C for 60 minutes to obtain thecomposite magnesium oxide expanding agent. The obtained composite magnesium oxide expanding agent has high volume expansion rate, the reaction activity of the composite magnesium oxide expanding agentis reduced along with increasing of the calcination temperature, and the composite magnesium oxide expanding agent is mainly used for compensating long-term shrinkage of mass concrete. The preparation method provided by the invention not only can greatly reduce the production cost of the magnesium oxide expanding agent, but also can treat industrial tailings and realize resource utilization.

Owner:TSINGHUA UNIV

Aluminate cement and preparation method thereof

The invention discloses aluminate cement and a preparation method thereof, and relates to the field of building materials. The aluminate cement comprises the following components in percentage by mass: (1) 55.0%-75.0% of aluminate cement clinker, (2) 3.0%-10.0% of barium slag, (3) 5.0%-15.0% of garnierite tailings, (4) 5.0%-15.0% of red mud, (5) 3.0%-10.0% of steel slag, and (6) 2.5%-5.0% of gypsum, wherein the content of aluminium oxide in the aluminate cement clinker is 47.0%-65.0%. The preparation method of the aluminate cement comprises the following steps: (1) preparing materials, (2) grinding, and (3) pulverizing. The aluminate cement has the characteristics of being high in hardening rate and high in hardening strength, and besides, effectively overcomes the defect that the long-term strength of the conventional aluminate cement is relatively low, and effectively uses various industrial wastes, and is a very ideal cement material.

Owner:苏州市德莱尔建材科技有限公司

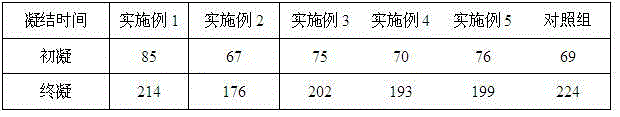

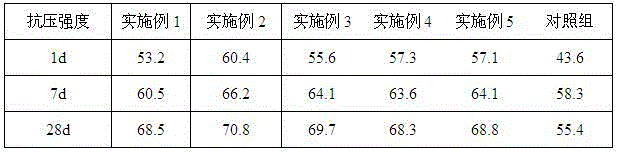

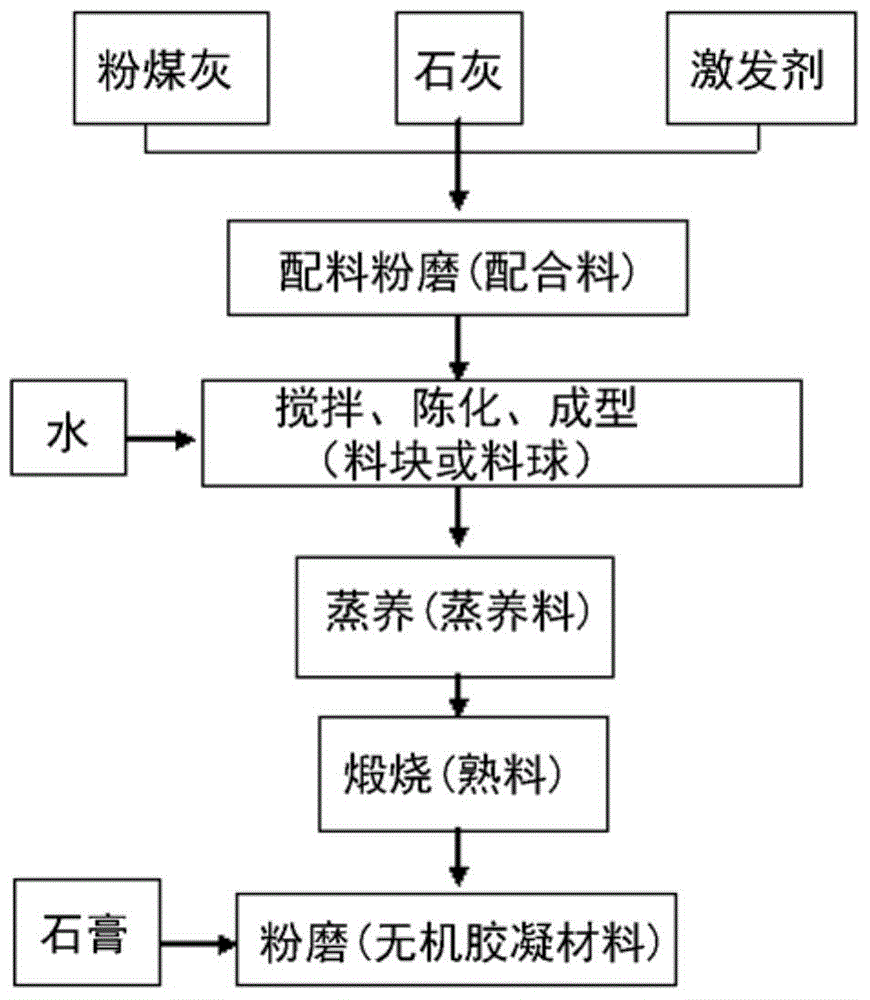

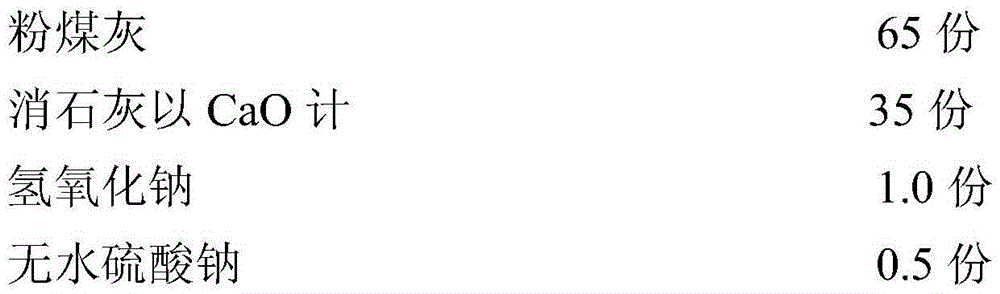

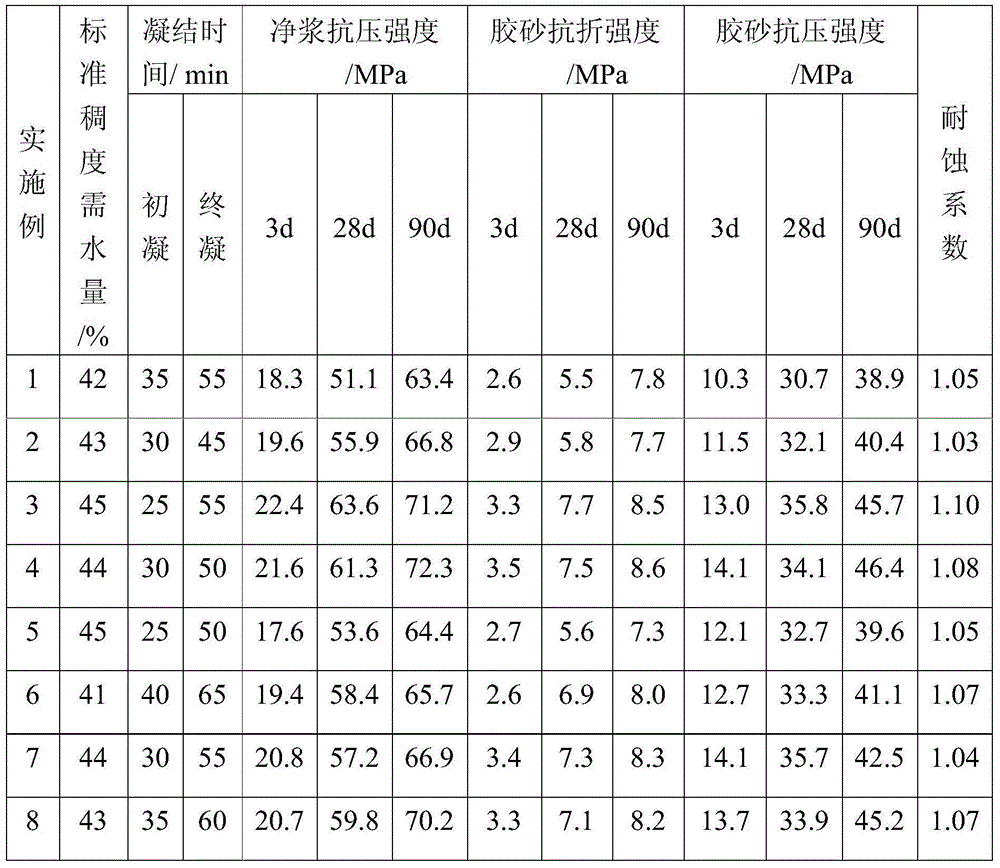

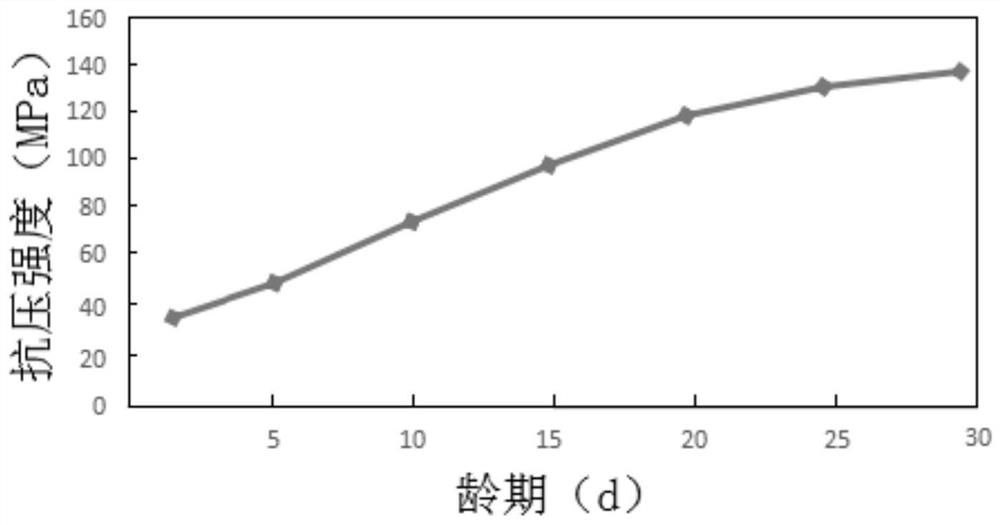

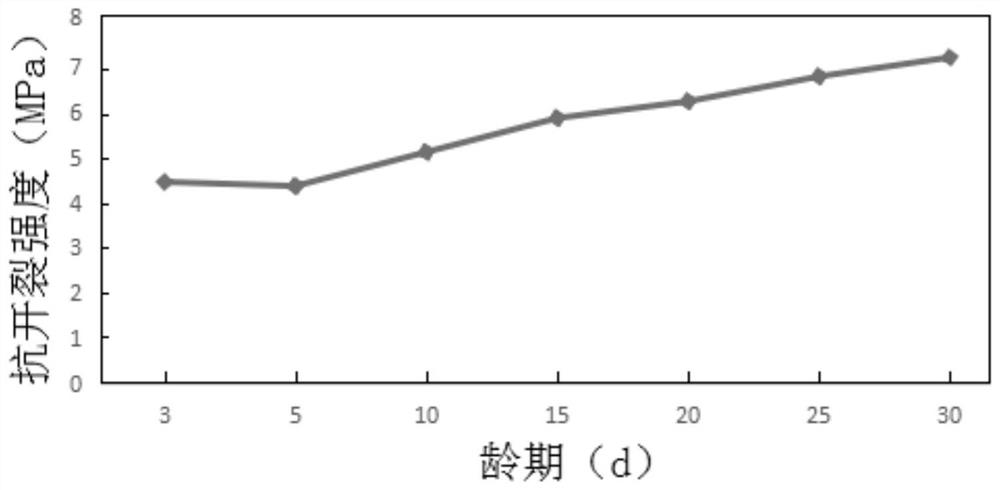

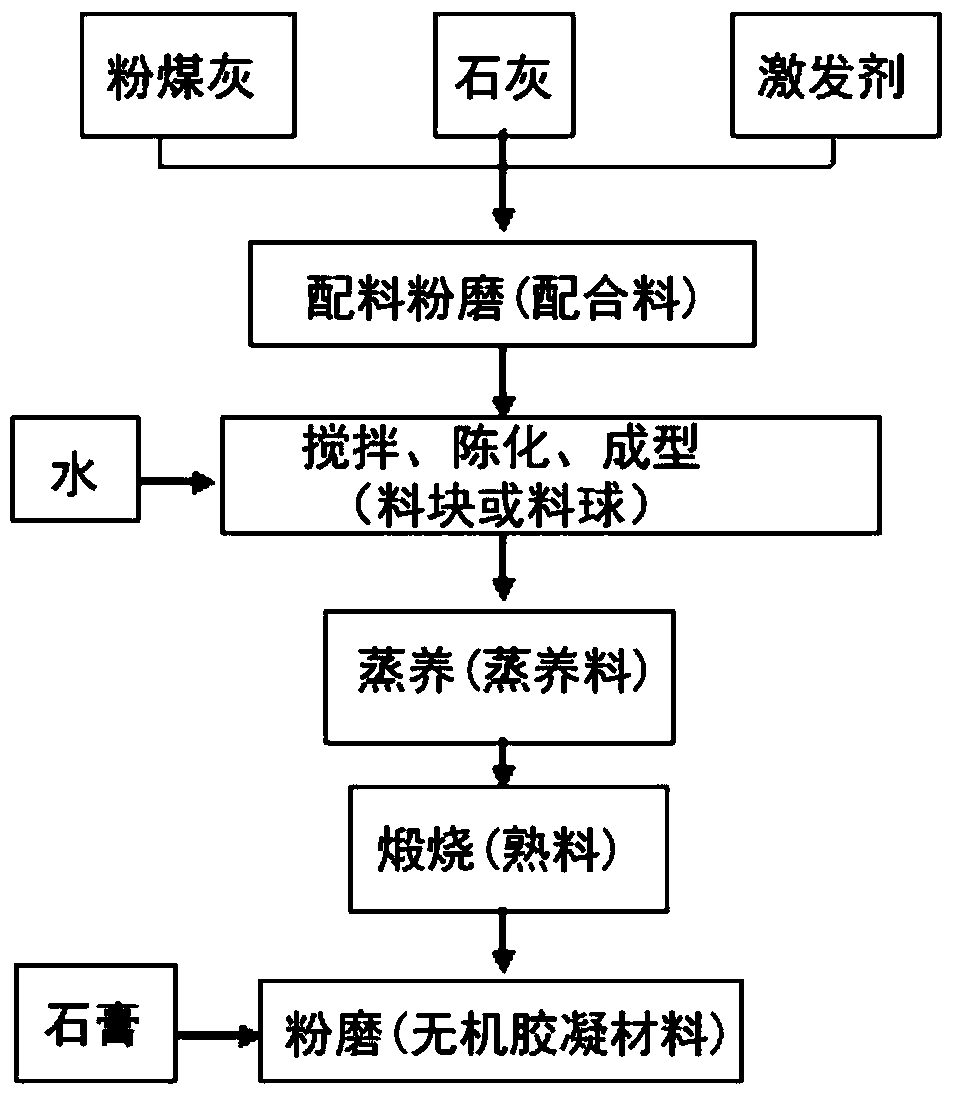

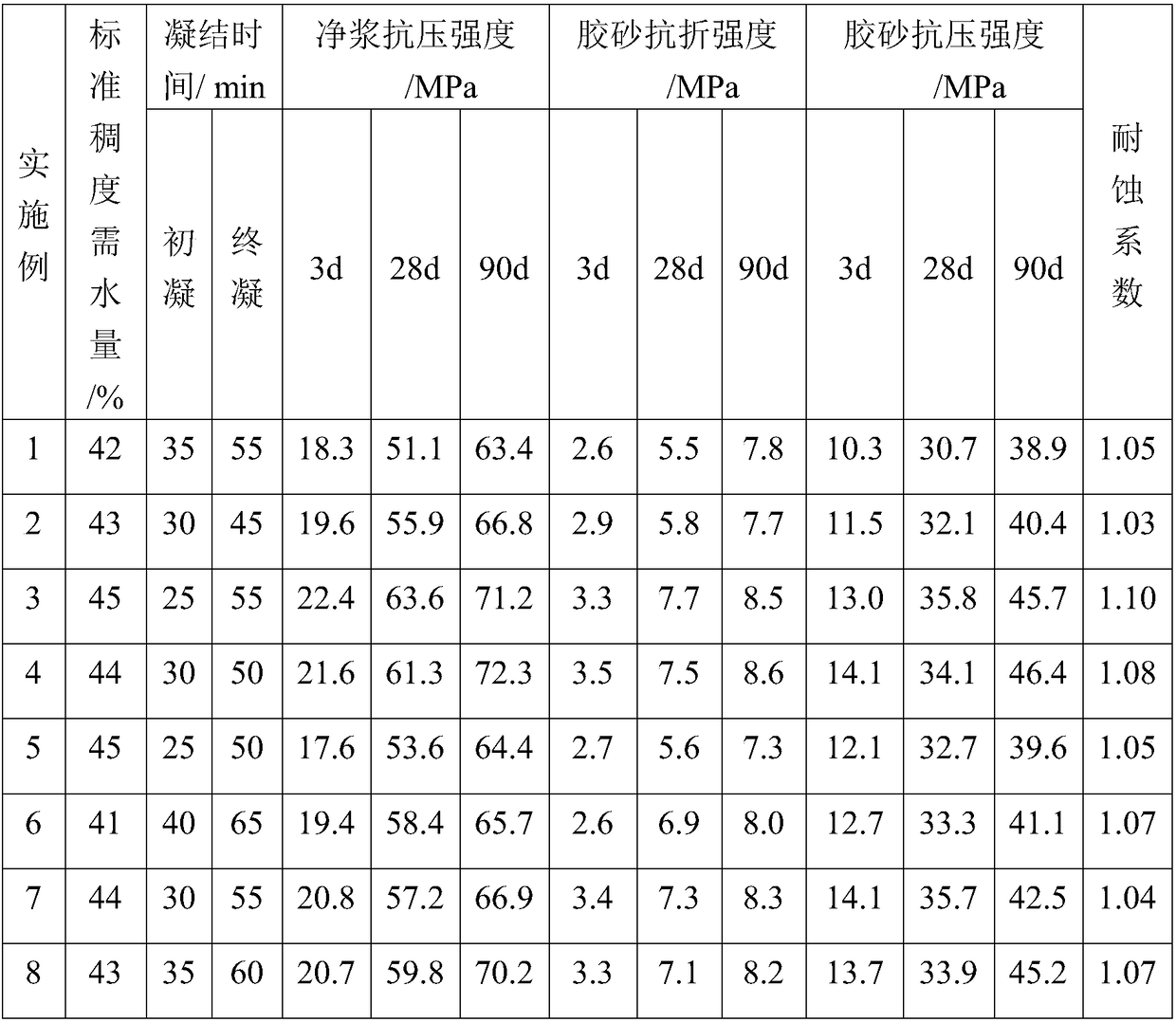

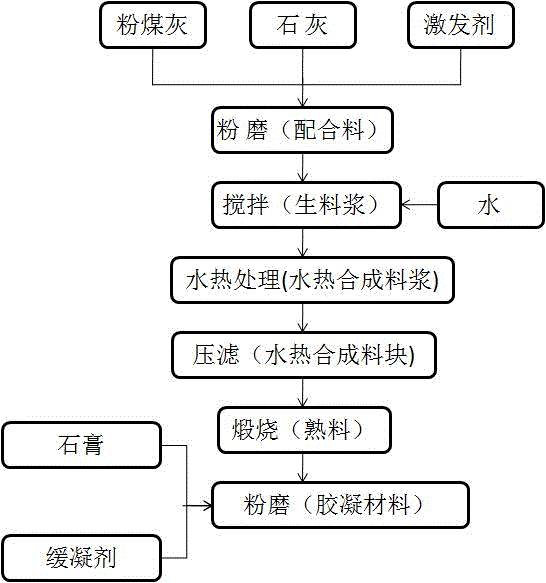

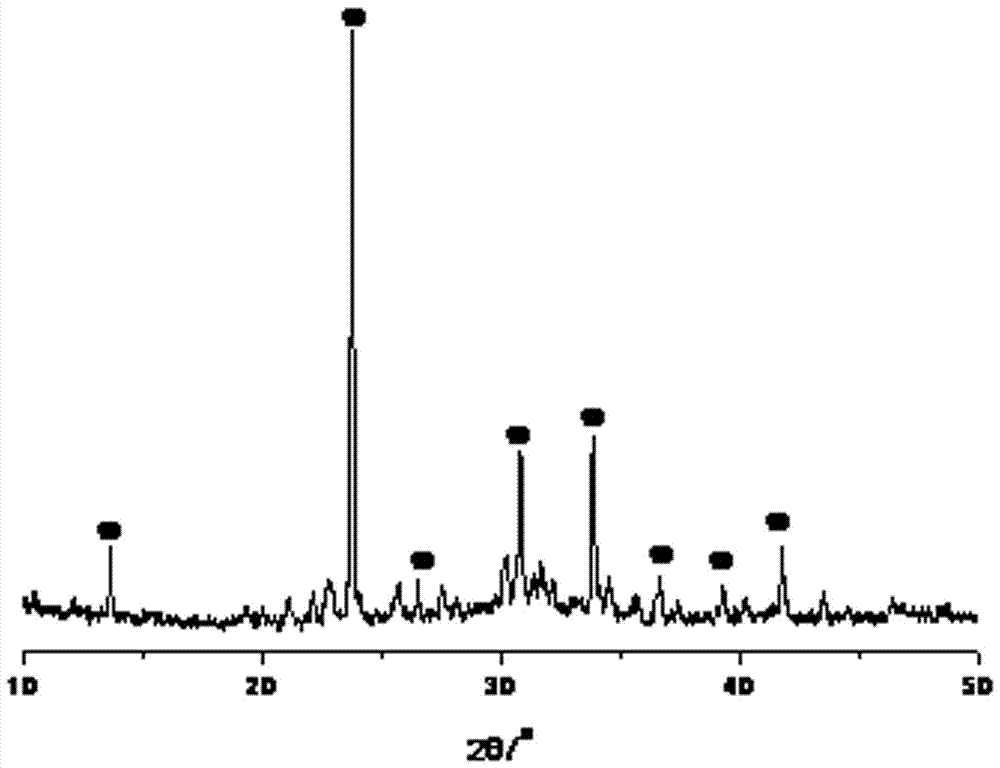

Inorganic cementing material and preparation method thereof

InactiveCN105985038AIncrease profitReduce occupancyCement productionSulfateUltimate tensile strength

The invention provides an inorganic cementing material and a preparation method thereof. The cementing material is obtained by jointly grinding grog obtained by steam curing and calcinating material blocks or material balls prepared from coal ash, lime, an exciting agent and water and gypsum. The preparation method includes the steps that by mass, 65-80 parts of coal ash, 20-35 parts of effective CaO of lime and 0.5-2.0 parts of the exciting agent are jointly ground into a batch mixture with the degree of fineness being 45 microns and the residue on sieve being smaller than 10%, 15-50 parts of water is added, the mixture is mixed to be uniform, then aging is conducted for 2-3 hours, the material blocks or the material balls are subjected to steam curing for 8-16 hours at the temperature of 90-98 DEG C after being formed, then calcinated for 15-120 minutes at the temperature of 750-1,000 DEG C and then air cooled or cooled in air, and the grog is obtained; 90-95 parts of the grog and 5-10 parts of gypsum are jointly ground till the specific area is 350-500 m<2> / kg, and the inorganic cementing material is prepared. Low-quality coal ash which is high in carbon content can be used as the main material of the inorganic cementing material, calcinating temperature and heat consumption are low, and a product has the advantages of being high in setting speed and hardening speed, high in long-term strength and good in water resistance and sulfate resistance.

Owner:HUAZHI ENERGY CONSERVATION HK

High-strength polyvinyl alcohol fiber reinforced cement-based composite material as well as preparation method and application thereof

PendingCN113045273AImprove early strengthShort setting timeSolid waste managementClimate change adaptationPolyvinyl alcoholPortland cement

The invention relates to the technical field of building materials, in particular to a high-strength polyvinyl alcohol fiber reinforced cement-based composite material and a preparation method and application thereof. The high-strength polyvinyl alcohol fiber reinforced cement-based composite material is prepared from the following raw materials in parts by weight: 100-130 parts of superfine Portland cement, 325-350 parts of an active mineral admixture, 215-230 parts of an inorganic admixture, 1-2 parts of a defoaming agent, 2-2.3 parts of a water reducing agent, 45-60 parts of water and 3-5 parts of polyvinyl alcohol fiber. According to the invention, a PVA-ECC material is applied to the ultra-high performance concrete to prepare the composite material, and the composite material is applied to preparation of an anti-seismic structure, a large-deformation structure and a composite structure.

Owner:XUCHANG UNIV

No-baking light foamed heat insulating and sound isolating material and its production process

InactiveCN1887783AHigh potential activityHydraulically hardSolid waste managementCeramicwareHigh activityUltimate tensile strength

The present invention is one kind of no-baking light foamed heat insulating and sound isolating material and its production process. The no-baking light foamed heat insulating and sound isolating material has high activity fly ash, which is produced based on one other patent of the present inventor, as basic material and some other components. It has high water resistance, high strength, high fireproof performance and high stability.

Owner:郑东风

High-performance gypsum water reducing agent

The invention relates to a high-performance gypsum water reducing agent, which is prepared from the following raw materials in parts by weight: 300 to 350 parts of polyoxyethylene ether, 20 to 30 parts of crylic acid, 10 to 20 parts of styrene, 5 to 10 parts of vinylphosphate, 1 to 5 parts of 2-acrylamide-2-methylpropanesulfonic acid, 580 to 650 parts of water, 1 to 5 parts of initiator and 1 to 3parts of molecular weight regulator; and the high-performance gypsum water reducing agent is further prepared from 10 to 30 parts of emulsion and 10 to 20 parts of nano-calcium carbonate. The water reducing agent can effectively decrease the later water absorption of gypsum and increase long-term performance.

Owner:徐州市贾汪区怀强工贸有限公司

No-baking light foamed heat insulating and sound isolating material and its production process

InactiveCN100384771CHigh potential activityHydraulically hardSolid waste managementCeramicwareHigh activityUltimate tensile strength

The present invention is one kind of no-baking light foamed heat insulating and sound isolating material and its production process. The no-baking light foamed heat insulating and sound isolating material has high activity fly ash, which is produced based on one other patent of the present inventor, as basic material and some other components. It has high water resistance, high strength, high fireproof performance and high stability.

Owner:郑东风

A kind of permeable concrete additive and preparation method thereof

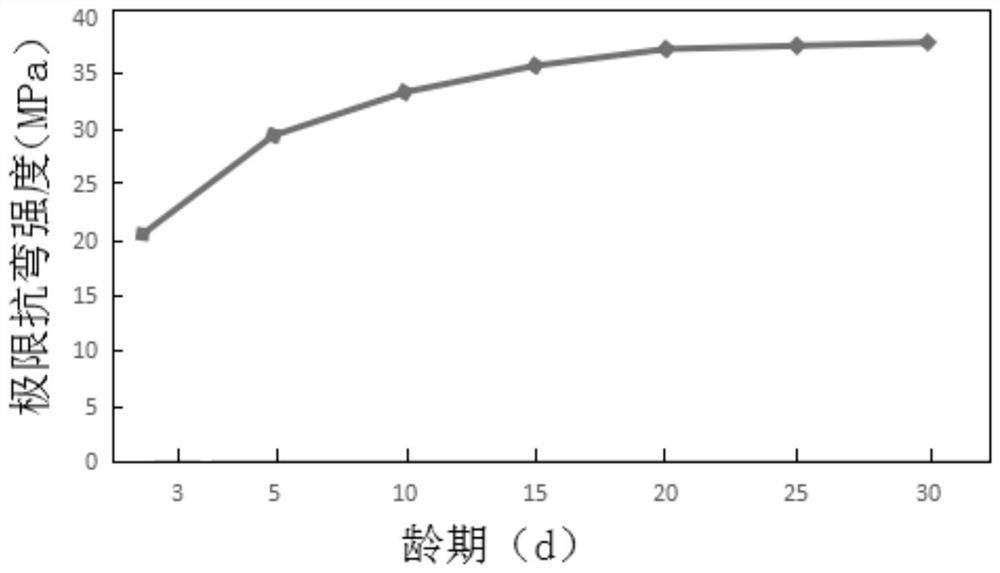

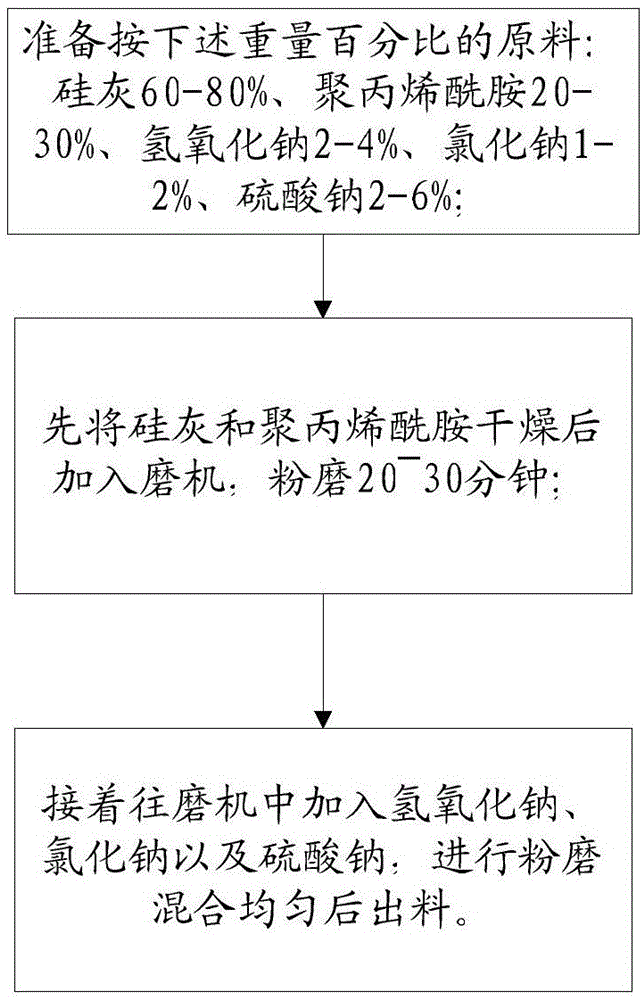

ActiveCN103787610BHigh compressive strengthHigh long-term strengthEconomic benefitsUltimate tensile strength

The invention provides a pervious concrete additive. The pervious concrete additive comprises the following raw materials in percentage by weight: 60-80% of silica fume, 20-30% of polyacrylamide, 2-4% of sodium hydroxide, 1- 2% of sodium chloride and 2-6% of sodium sulfate. The invention also provides a preparation method of the pervious concrete additive. Compared with previous concrete without the additive, the previous concrete with the additive has the advantages that the compressive strength of 1-28 days of the previous concrete is obviously improved, and the long-term strength is also improved. The pervious concrete additive can be used for effectively accelerating the construction progress of the previous concrete, shortening the turnover period of fields, equipment and labor and increasing economic benefits.

Owner:FUJIAN CONSTR ENG GRP BUILDING MATERIAL SCI & TECH DEV

Gypsum water-reducing agent

The invention relates to a gypsum water-reducing agent which is prepared from the following raw materials in parts by weight: 300 to 350 parts of polyoxyethylene ether, 20 to 30 parts of acrylic acid,10 to 20 parts of styrene, 5 to 10 parts of ethylenephosphonic acid, 1 to 5 parts of 2-acrylamide-2-methyl propane sulfonic acid, 580 to 650 parts of water, 1 to 5 parts of initiator, 1 to 3 parts ofmolecular weight modifier, and 10 to 30 parts of emulsion. According to the water-reducing agent, the water absorption rate of gypsum at the later period can be effectively reduced, and the long-timeperformance is improved.

Owner:徐州市贾汪区怀强工贸有限公司

A large amount of fly ash concrete and its preparation method

ActiveCN107602023BOvercome the defect of low early strengthHigh strengthSuperplasticizerCarboxylic acid

The invention provides large-dosage fly ash concrete and a preparation method thereof. The large-dosage fly ash concrete is prepared from the following raw materials: cement, fly ash, mineral powder,gravel, river sand, water, a modified reinforcing agent and a polycarboxylate superplasticizer, wherein the modified reinforcing agent is prepared from bentonite, attapulgite, lignosulfonate, sodium sulfate, calcium hydroxide, triethanolamine maleate and water. The preparation method comprises the following steps: adding the cement, the mineral powder, the fly ash, the modified reinforcing agent,the gravel and the river sand into a mixer; performing dry mixing for 30-40min; adding the water and the superplasticizer into the mixer; mixing for 10-15min to obtain the large-dosage fly ash concrete. According to the large-dosage fly ash concrete and the preparation method thereof provided by the invention, a multifunctional modified synergistic for large-dosage fly ash concrete is prepared from the roasted bentonite together with attapulgite, organic and inorganic activators and a surfactant; by combining the multifunctional modified synergistic with an early-strength polycarboxylate superplasticizer, the aim of improving the strength, compactness and durability of the large-dosage fly ash concrete can be achieved.

Owner:南京平达绿色建材科技有限公司

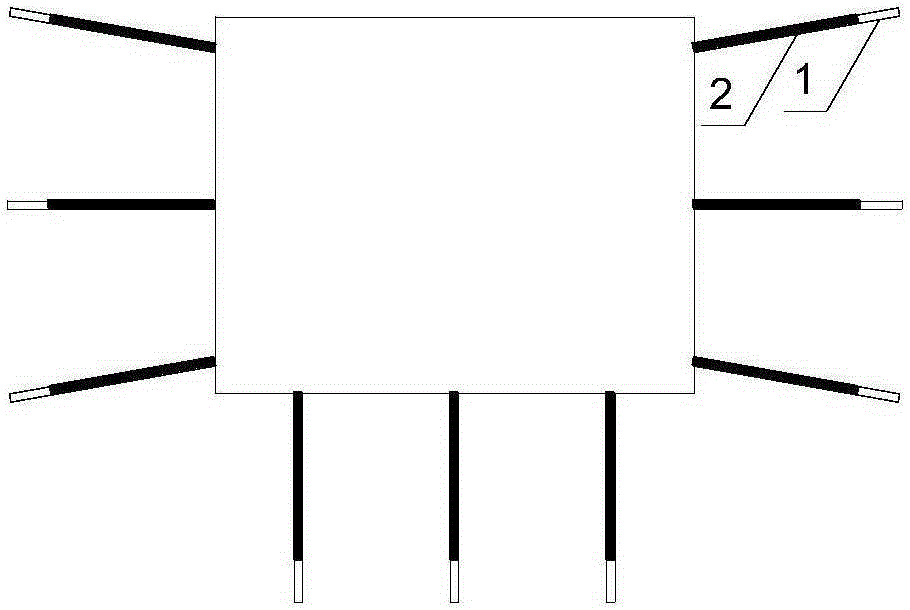

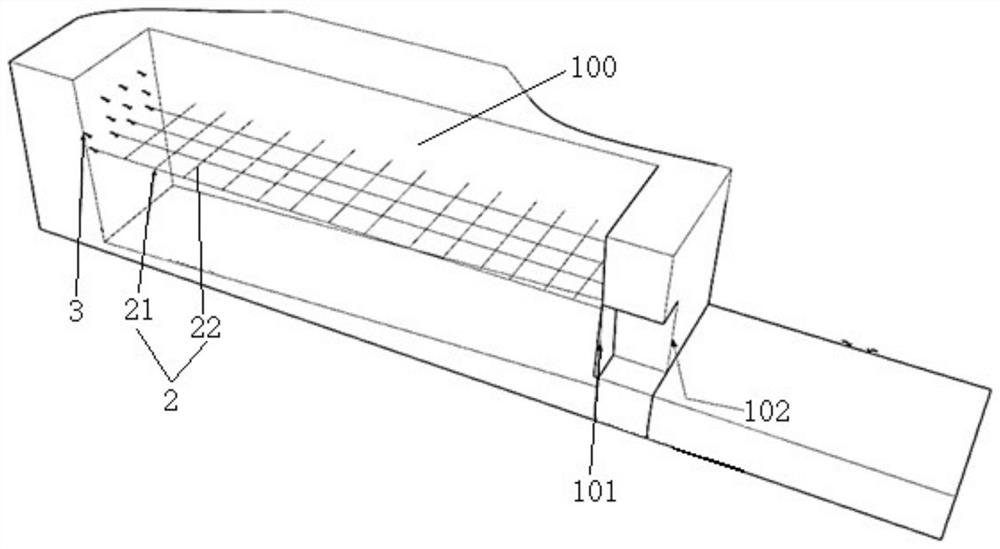

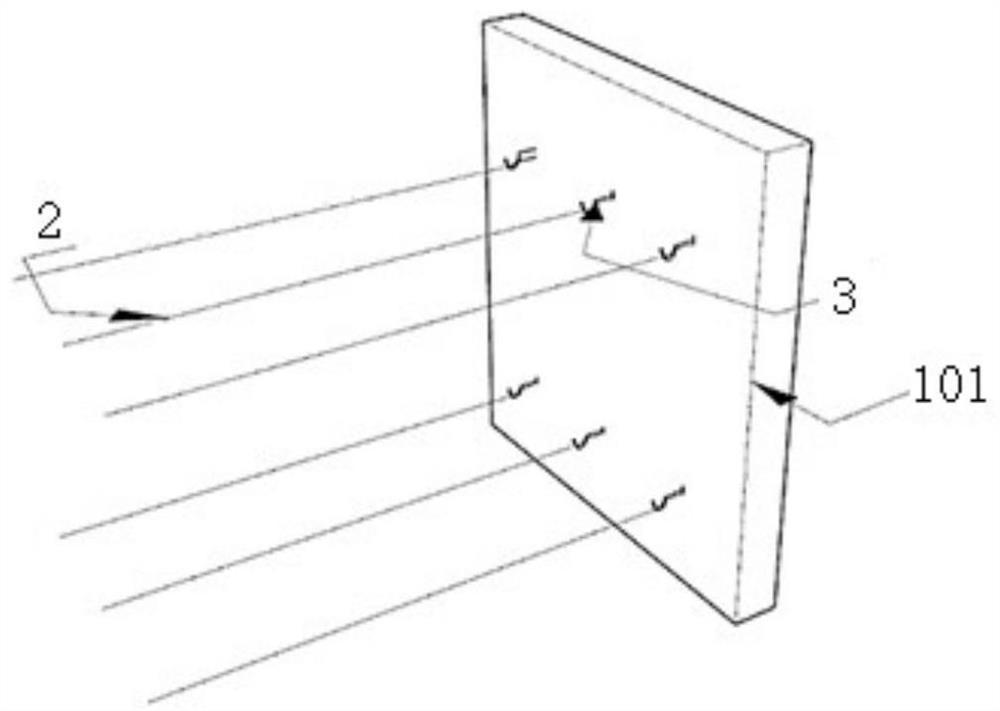

Silica sol slow seepage reinforcement method for argillaceous soft rock

ActiveCN105201528BReduce viscosityGood injectabilityUnderground chambersTunnel liningStructure of the EarthDissolution

Provided is a silica sol slow infiltration reinforcing method for argillaceous soft rock, comprising the following steps: a. lithological changes, pore development characteristics and hydrogeological conditions of roadway surrounding rock are evaluated, and grouting hole (1) parameters and silica sol ratio are determined; b. grouting holes (1) are constructed before argillization, grouting pipes (2) are mounted and the holes are sealed, and silica sol is injected, and in the same time period the silica sol quickly fills and reinforces macrofissures under the drive of a grouting pressure; and c. when the grouting pressure is reduced to a certain value, and the low pressure is maintained for a long time, and in the same time period the silica sol slowly diffuses and enters microfissures of the rock mass under the drive of a capillary force to form a highly-compact reinforced mass, such that the reinforcing of the surrounding rock is complete. The method not only has the macrofissures filled, but also enables microchannels of water molecules and air molecules in a mud rock matrix to be closed, substantially hinders microcosmic effects such as adsorption, dissolution and weathering, improves the compactness and integrity of microstructures of the mud rock, reduces the permeability, and improves the deformation resistance and durability of the rock mass.

Owner:CHINA UNIV OF MINING & TECH

A kind of cementitious material gypsum-based ecological cement and production method thereof

ActiveCN104496236BGood energy saving and emission reduction effectLow priceEnvironmental engineeringToxic industrial waste

Owner:JINGMEN SHENGLONG TECH

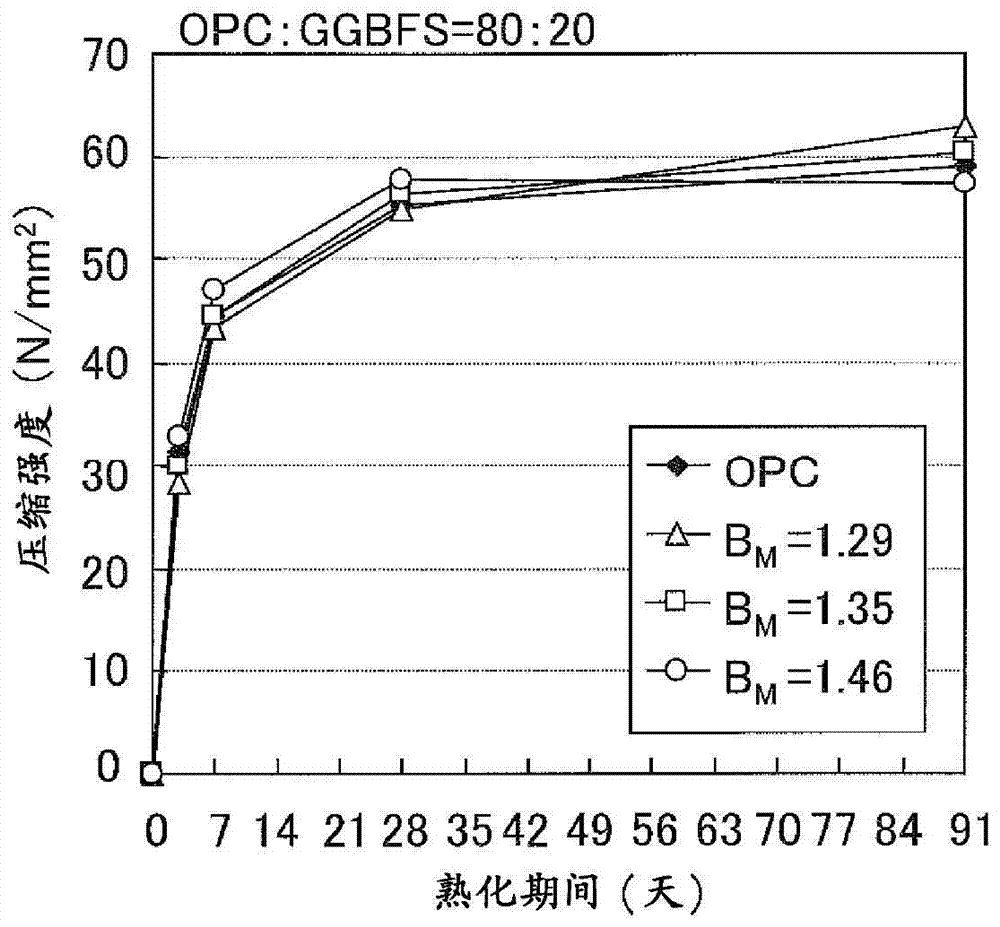

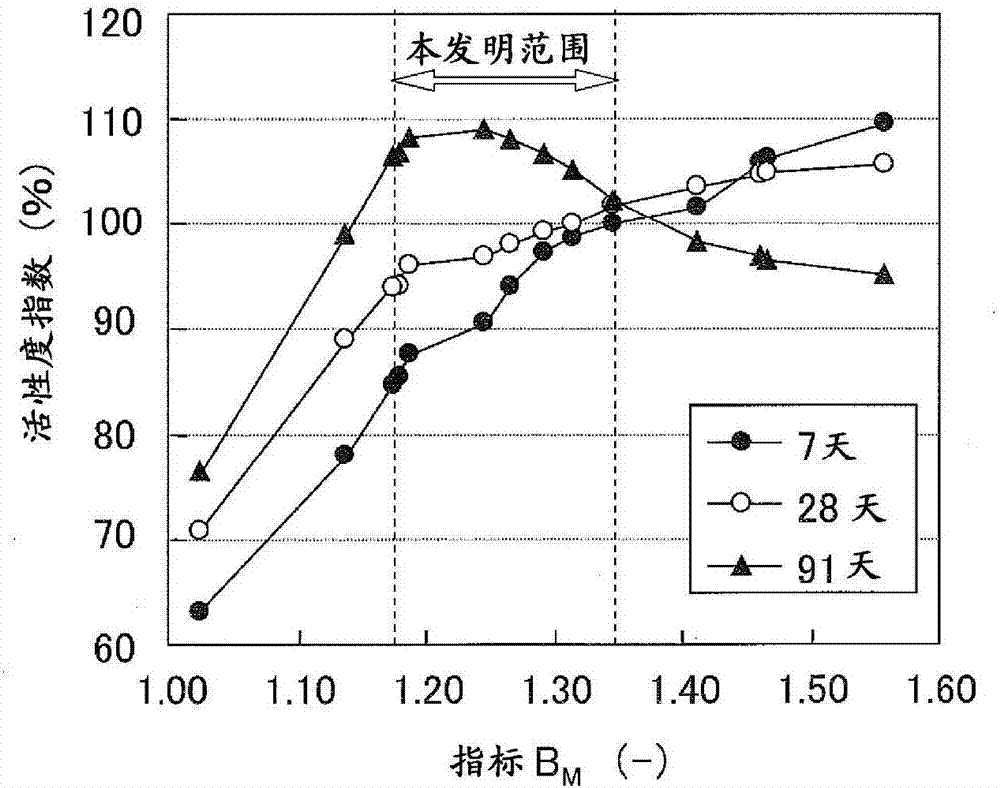

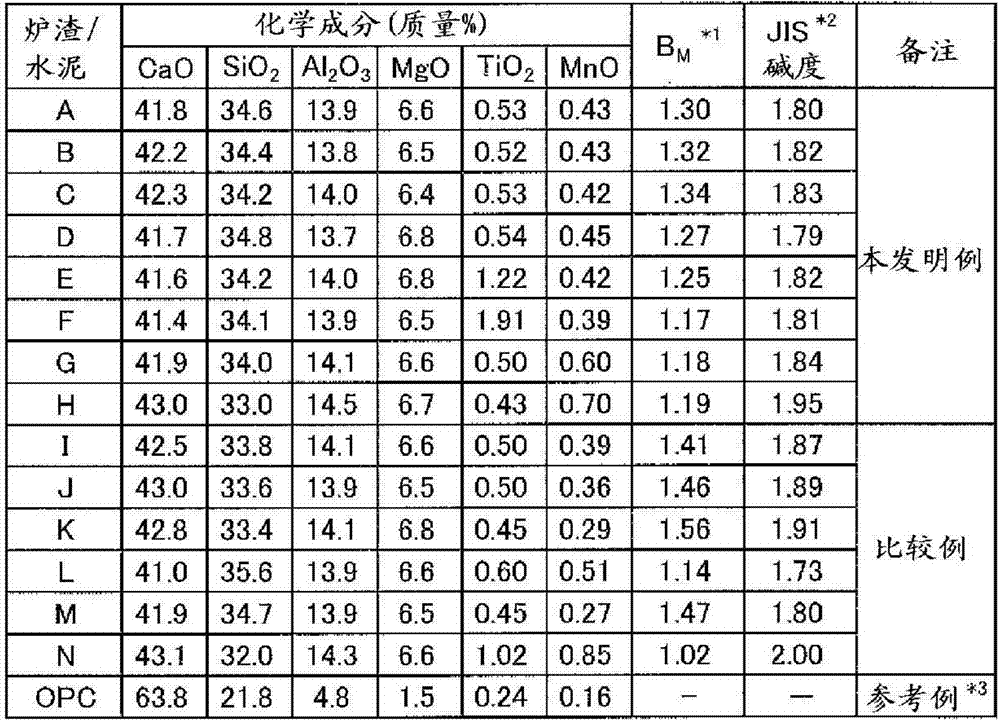

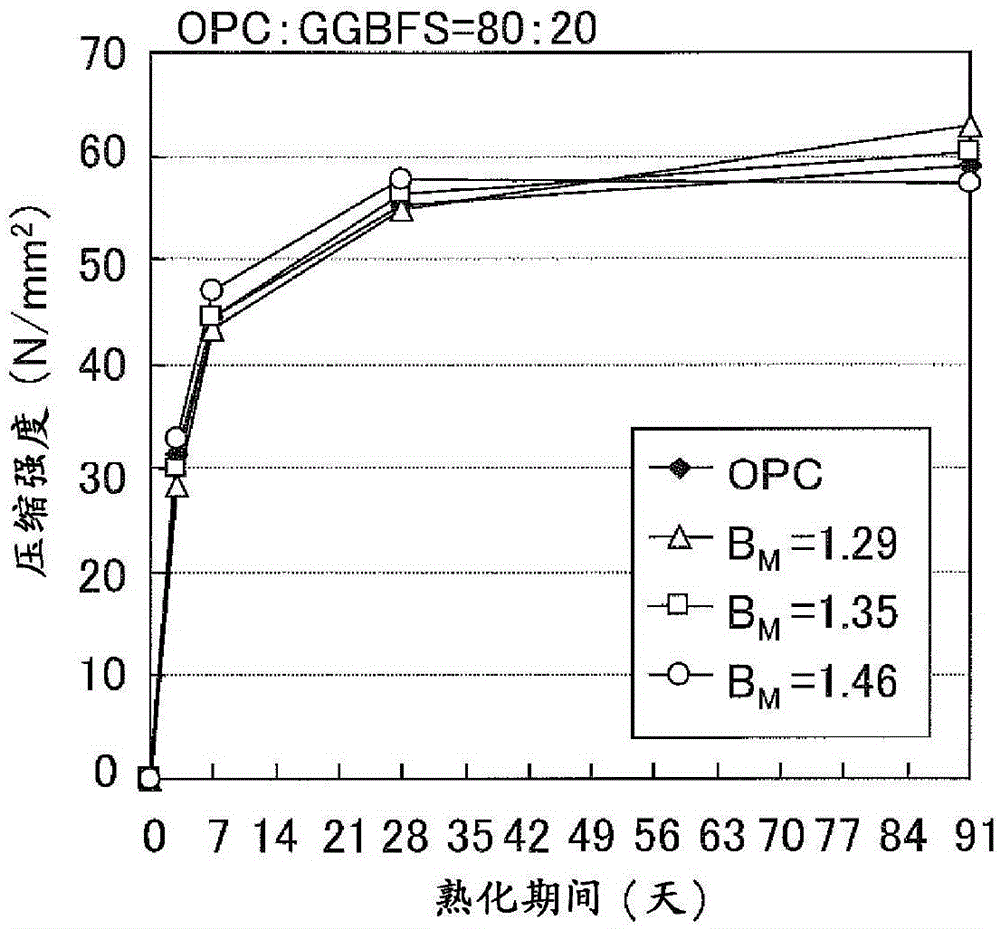

Water-quenched blast furnace slag for cement raw material and its screening method

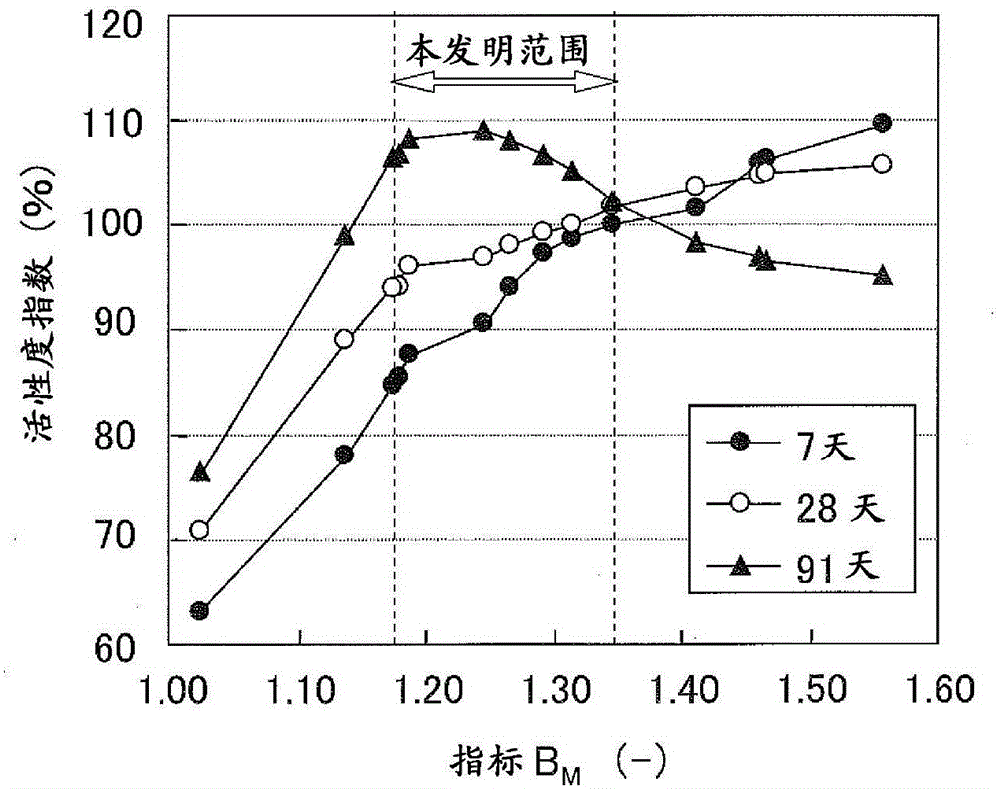

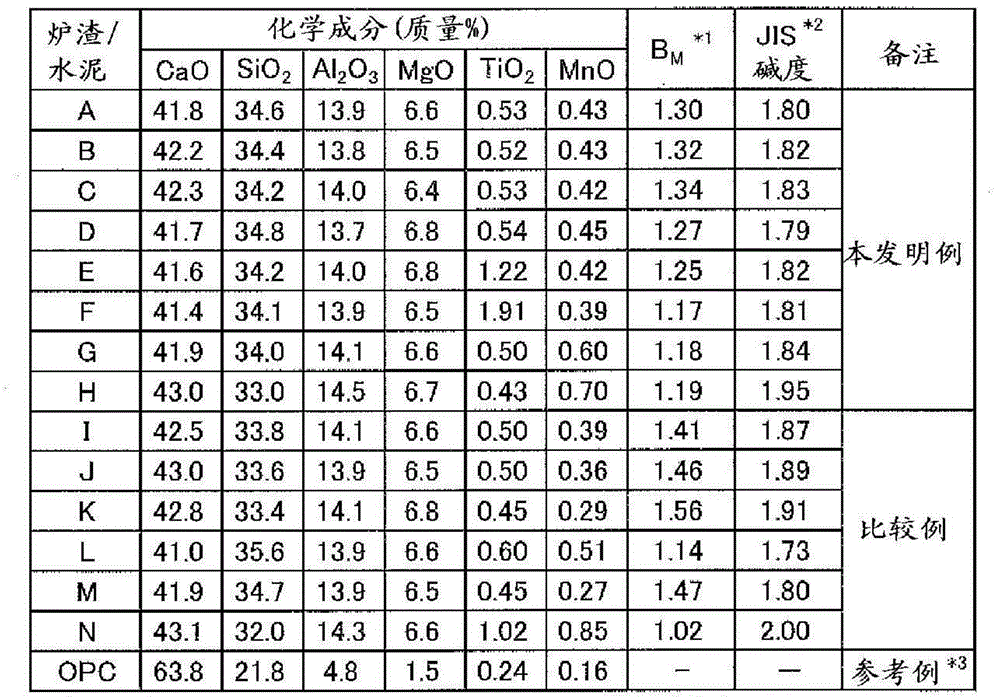

ActiveCN105143137BHigh long-term strengthShorten speedCement productionRecycling and recovery technologiesChemical compositionSlag

Provided are a granulated blast furnace slag suitable as cement starting material for use in high-temperature regions where the annual average temperature is 22°C or above, and a screening method for the same. Granulated blast furnace slag having a chemical composition in which the content (mass%) of CaO, Al2O3, MgO, SiO2, TiO2, and MnO satisfies the following formula (1) is screened, obtaining a granulated blast furnace slag for use as cement starting material in high-temperature regions where the annual average temperature is 22°C or above. 1.17 ≤ BM ≤ 1.35 … (1) In formula 1, BM = (CaO + Al2O3 + MgO) / (SiO2 - 0.13 × TiO2 - MnO (CaO, Al2O3, MgO, SiO2, TiO2, and MnO represent content (mass%) of the oxides included in the granulated blast furnace slag.))

Owner:JFE STEEL CORP

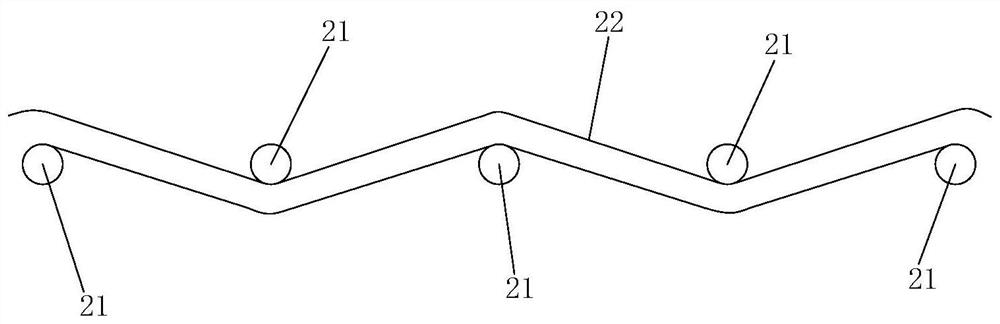

A fiber woven mesh reinforced tailings solidified filling structure and its filling process

ActiveCN112523801BIncrease profitReduce unit consumptionMaterial fill-upFiberArchitectural engineering

The invention discloses a fiber braided net reinforced tailings solidified filling structure and its filling process. The filling body contains several layers of fiber braided nets. The grid gap filling tailings filling is solidified to form a filling body. In the field of mine filling technology, the invention innovatively uses composite fiber reinforced materials with high tensile strength to connect into a network to lay gobs, thereby enhancing the mechanical properties of the tailings filling body. The construction is convenient and convenient during the application process, and can effectively reduce cement, etc. The loss of cementitious material can significantly reduce the comprehensive filling cost while increasing the curing strength. It is especially suitable for the approach type and upward layered stope filling with a small stope exposure height. It is a kind of good economic benefit and limited The tailings filling scheme with few conditions improves the overall performance of the tailings filling body in the goaf of the mine, and has good economic benefits and promotion value.

Owner:CENT SOUTH UNIV

A kind of inorganic cementitious material resistant to water and sulfate erosion and preparation method thereof

Provided are an inorganic cement material and a manufacturing method thereof, the cement material being manufactured from, in parts by mass, 90-95 parts clinker obtained from steam curing and calcining material blocks or material balls manufactured from 65-80 parts fly ash, 20-35 parts of lime measured in terms of active CaO, 0.5-2 parts stimulating agent, and 15-50 parts water; and 5-10 parts gypsum. The present inorganic cement material uses low-quality fly ash with high carbon content as the main raw material, with a low calcination temperature and low heat consumption.

Owner:HUAZHI ENERGY CONSERVATION HK

Flyash excitant

The flyash excitant has two different compositions. That for no-steel bar concrete consists of mirabilite 10-30 wt%, calcium chloride 10-30 wt%, sodium chloride 10-20 wt%, efficient water reducing agent 10-25 wt%, calcium lignosulfonate 1.5-7.0 wt% and ardealite 5-15 wt% other than carrier material. That for reinforced concrete consists of mirabilite 10-30 wt%, calcium chloride 10-15 wt%, sodium chloride 10-20 wt%, calcium nitrite 20-30 wt% efficient water reducing agent 6-10 wt%, calcium lignosulfonate 2-5 wt% and ardealite 5-15 wt% other than carrier material. The flyash excitant can excite the latent activity of flyash effectively so as to increase the added amount of flyash in concrete and lower the cost of concrete product.

Owner:葫芦岛市辽西混凝土外加剂有限公司

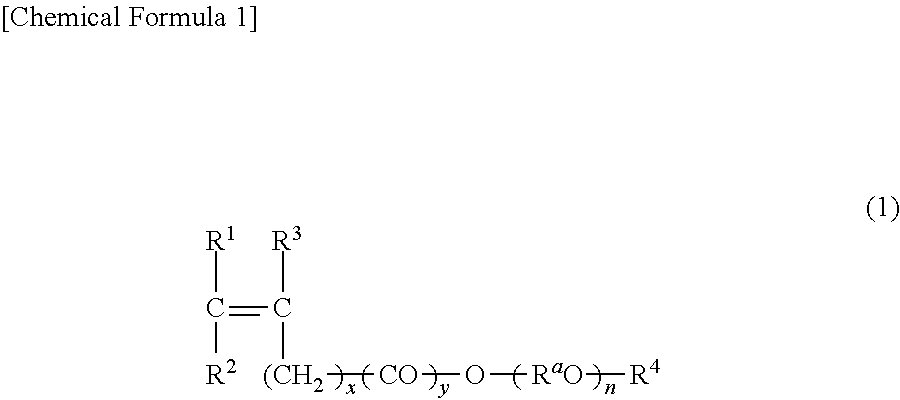

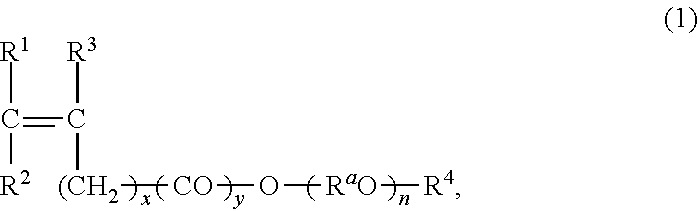

Cement additive, cement admixture, cement composition, molded body, and method for improving strength of molded body

Provided is an additive for concrete in which viscosity of a cement composition is low and fluidity is high at an initial stage of casting even when the additive is added, and long-term strength of concrete or the like improves by the addition. A cement additive comprising a water-absorbent resin, wherein the water-absorbent resin is formed by polymerizing a monomer mixture containing no less than 50 mol % of a nonionic non-crosslinkable monomer and no less than 0.1 mol % of a nonionic crosslinkable monomer, and a content of an anionic monomer in the monomer mixture is no more than 20 mol %.

Owner:NIPPON SHOKUBAI CO LTD

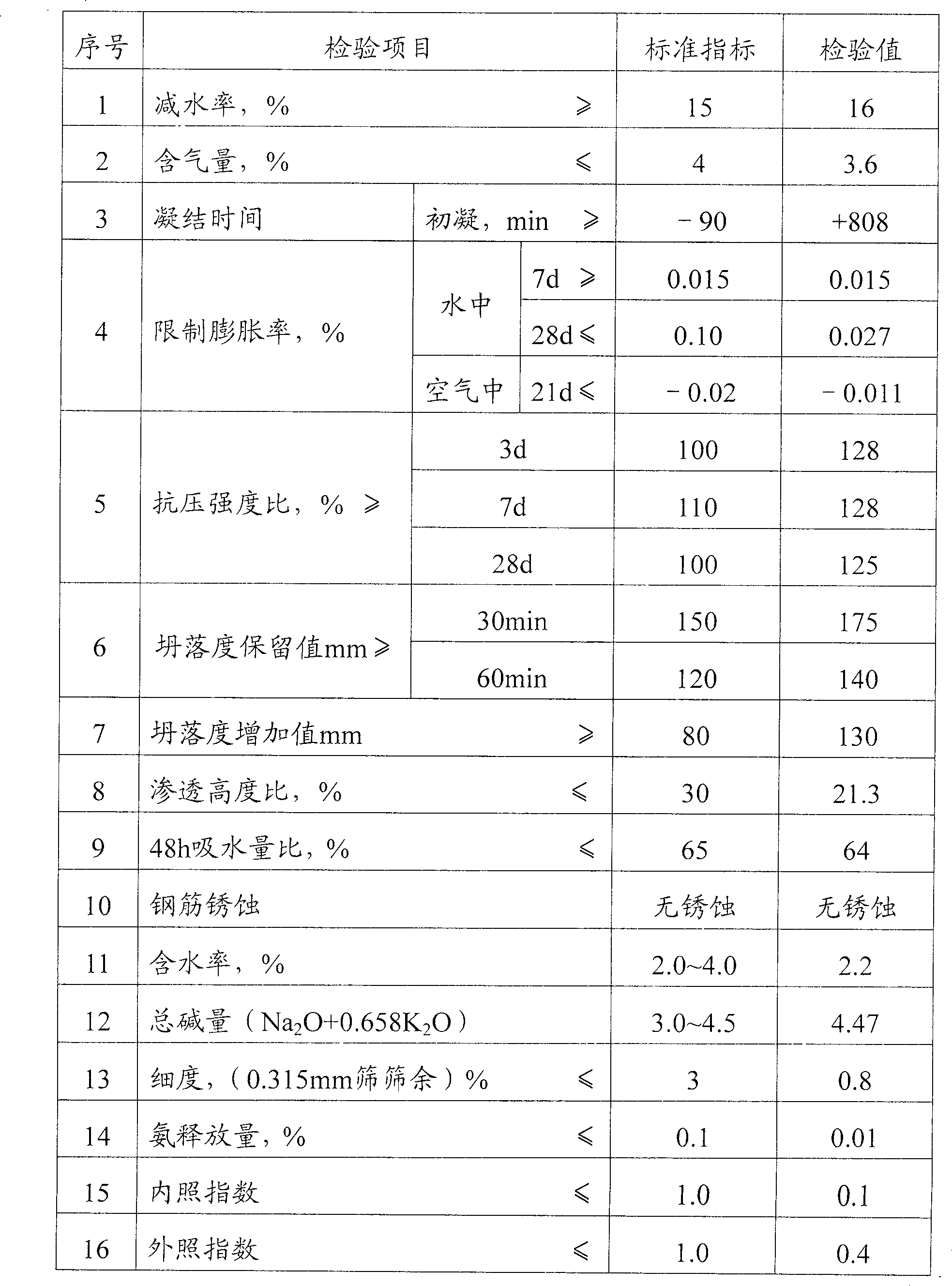

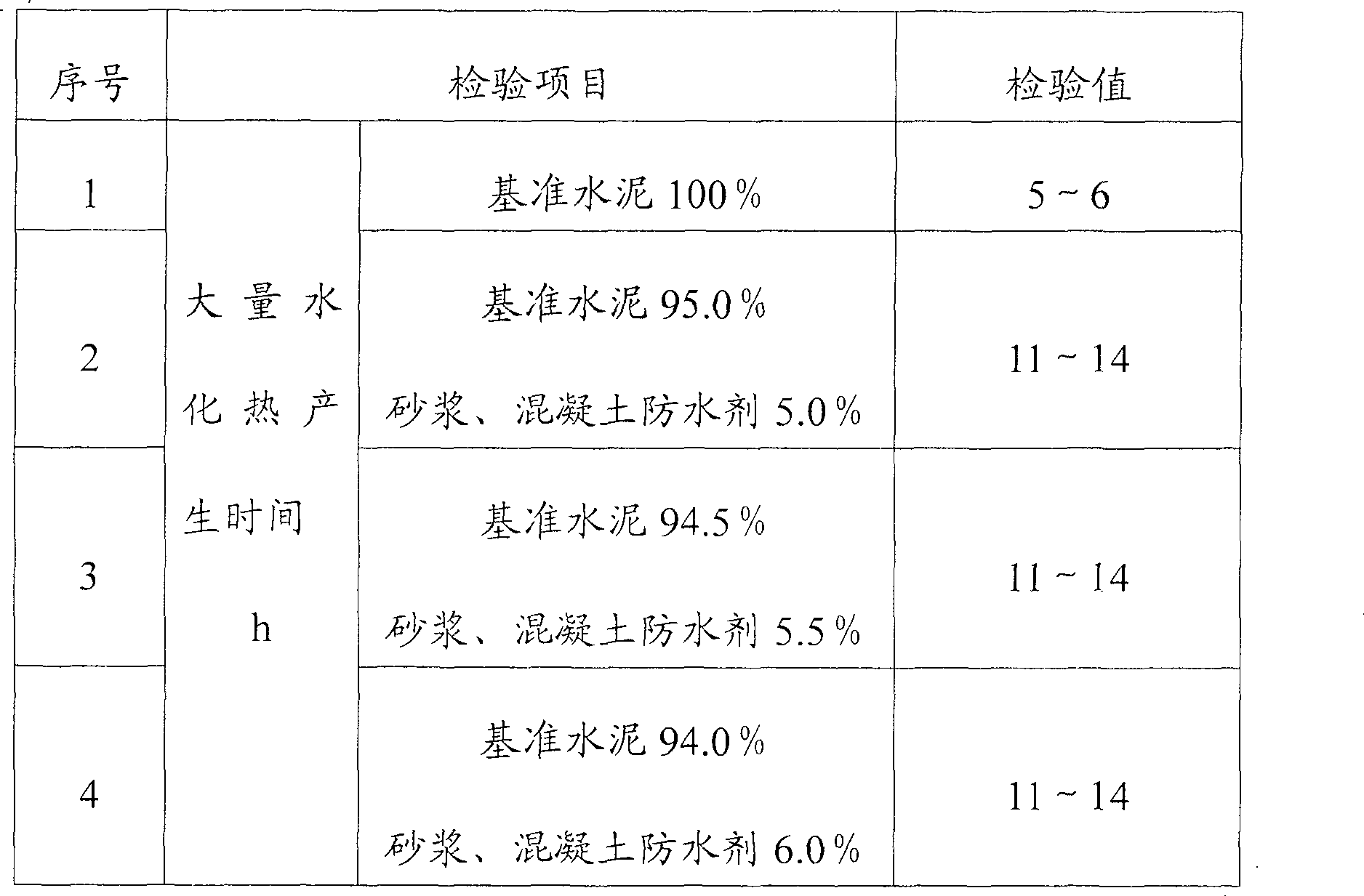

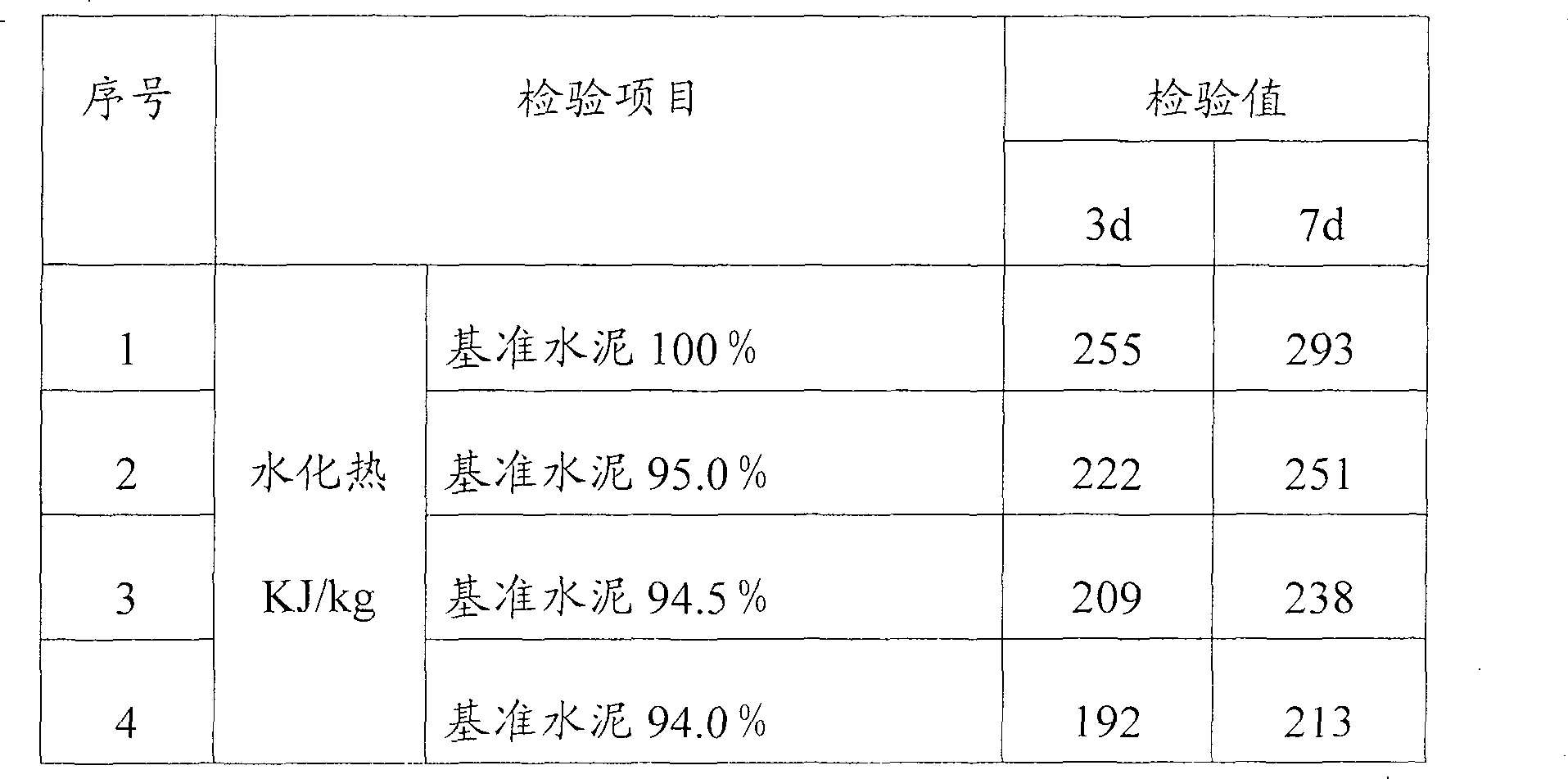

Sand pulp concrete waterproof agent and method for making same

The invention relates to a mortar and concrete waterproofing agent. The waterproofing agent is characterized in that it contains the following components by weight: 70-90 parts of activated zeolite powder, 0.3-2 parts of silane coupling agent, 2-5 parts of stearic acid, and 0.007-0.05 parts of alkylphenol polyoxyethylene ether , 3-10 parts of magnesia lime, 1-6 parts of gypsum, and 5-10 parts of polypropylene fiber. The invention also relates to a preparation method of the above-mentioned mortar and concrete waterproofing agent. The waterproofing agent can not only improve the compactness, compressive strength and waterproof and impermeable performance of concrete; it can also prevent temperature difference cracks by delaying and reducing the heat release of hydration, and reduce the shrinkage of cement gel to reduce the drying shrinkage of concrete. Produce micro-expansion in concrete to compensate for shrinkage cracks and other ways to improve the crack resistance of concrete; at the same time, it can also improve the workability of mortar and concrete, effectively inhibit the alkali-aggregate reaction, and improve the long-term strength of concrete and enhance durability . It is especially suitable as an admixture for mortar and concrete.

Owner:JINHUA XINSHENG ZEOLITE DEV

Anti-corrosion anti-cracking reinforcing agent composition and preparation method thereof

The invention relates to an anti-corrosion anti-cracking reinforcing agent composition for concrete, mortar, and net slurry used in injection (first-aid repair) engineering, and a preparation method thereof. The composition comprises the following components on a percentage basis: 2-50% of micro-expansive powder, 5-30% of reinforcing powder, 5-20% of anti-corrosion compacting agents, 10-20% of plasticizers, 1-6% of catalysts, and 10-60% of carriers. The composition of the invention prepares solid and liquid products by processes of melting refinement, polymerization, ball milling, jet milling, complex formulation, and the like, and thus meets construction process requirements of different first-aid repair endurance engineering.

Owner:四川巨星新型材料有限公司

Granulated blast furnace slag for use as cement starting material and screening method for same

ActiveCN105143137AHigh long-term strengthShorten speedMetal recyclingCement productionChemical compositionSlag

Provided are a granulated blast furnace slag suitable as cement starting material for use in high-temperature regions where the annual average temperature is 22°C or above, and a screening method for the same. Granulated blast furnace slag having a chemical composition in which the content (mass%) of CaO, Al2O3, MgO, SiO2, TiO2, and MnO satisfies the following formula (1) is screened, obtaining a granulated blast furnace slag for use as cement starting material in high-temperature regions where the annual average temperature is 22°C or above. 1.17 ≤ BM ≤ 1.35 … (1) In formula 1, BM = (CaO + Al2O3 + MgO) / (SiO2 - 0.13 × TiO2 - MnO (CaO, Al2O3, MgO, SiO2, TiO2, and MnO represent content (mass%) of the oxides included in the granulated blast furnace slag.))

Owner:JFE STEEL CORP

A kind of cementitious material using fly ash as raw material and preparation method thereof

Owner:HOHAI UNIV

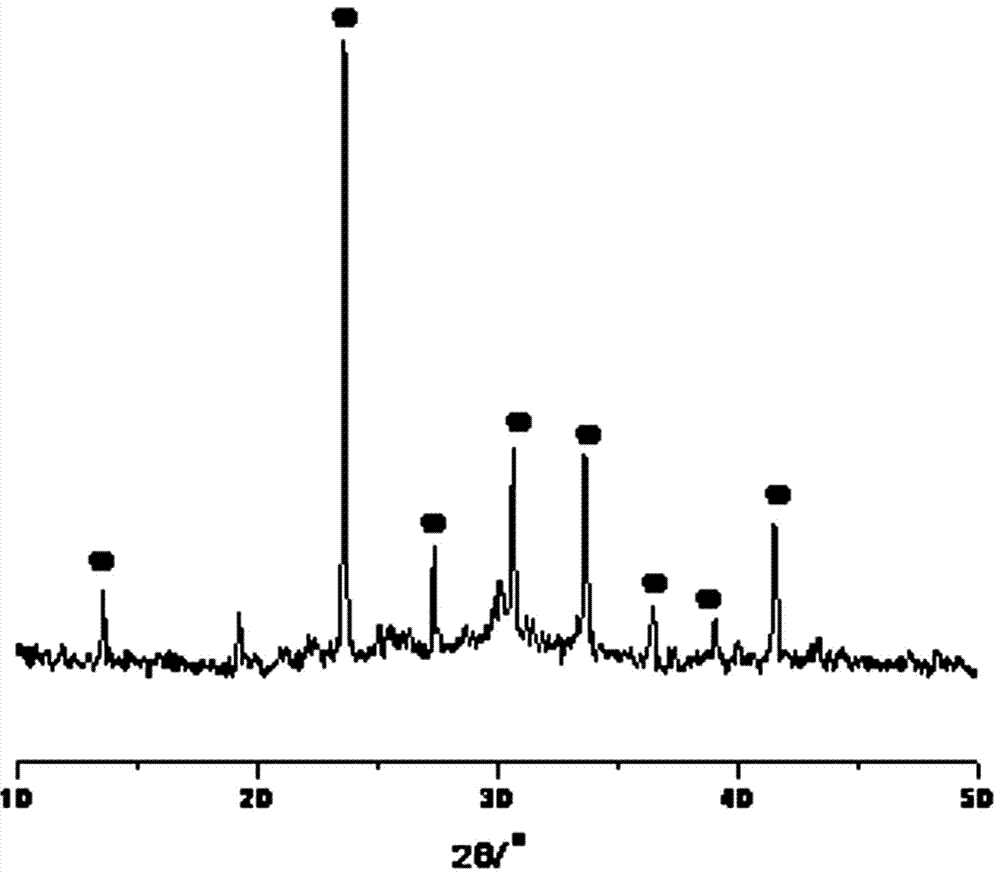

A modified calcium aluminophosphate mineral

InactiveCN105502981BHigh early hydration activityHigh long-term strengthTime rangeCompressive strength

The invention discloses a modified calcium aluminophosphate mineral. The modified calcium aluminophosphate mineral is obtained in the mode that raw materials, a modifying agent and a mineralizing agent are calcined at the temperature of 1,450-1,550 DEG C, the heat preservation time ranges from 1 h to 3 h, and the temperature is rapidly reduced to the indoor temperature; the modifying agent is BaO or SrO. The modified calcium aluminophosphate mineral is high in early-stage hydration activity, the 7d hydration degree is 80% or above, and the 7d hydration degree is higher than that of non-modified calcium aluminophosphate mineral by 20% or above; the compressive strength is remarkably improved, the long-term strength is continuously increased, the resultant temperature of the modified calcium aluminophosphate mineral is reduced by about 30-70 DEG C, an energy saving effect and a cost reducing effect are remarkable, and the modified calcium aluminophosphate mineral is suitable for large-scale industrial application and popularization.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com