A kind of permeable concrete additive and preparation method thereof

A technology of permeable concrete and additives, applied in the field of building materials, can solve the problems of lack of breathability and permeability of rain and snow, lack of natural water resources to moisten vegetation, and increase the burden of dredging system, so as to achieve simple and easy operation and ensure construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

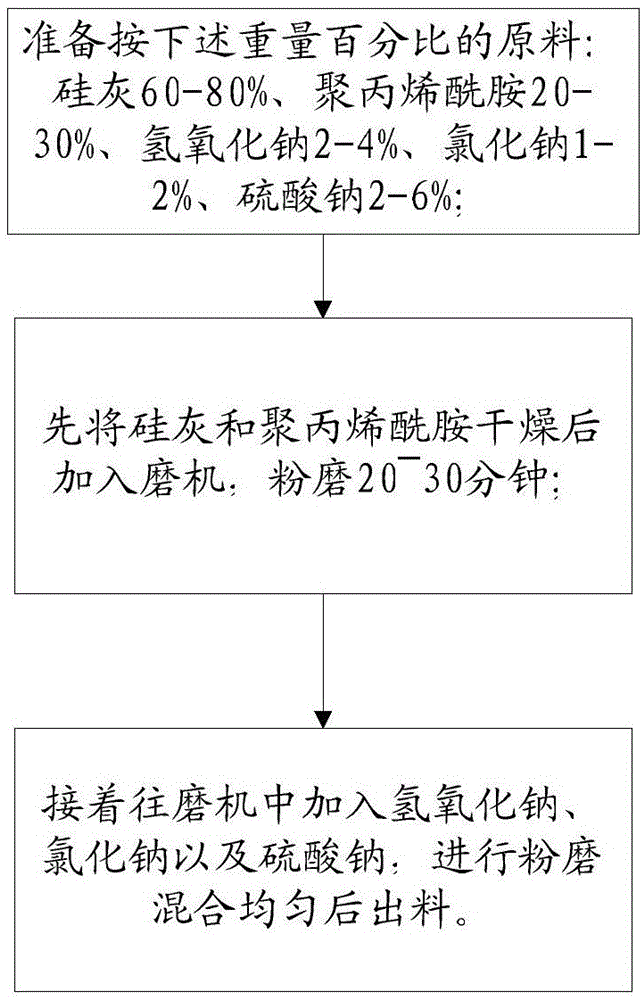

[0020] refer to figure 1 Shown, the preparation method of a kind of permeable concrete additive of the present invention comprises the steps:

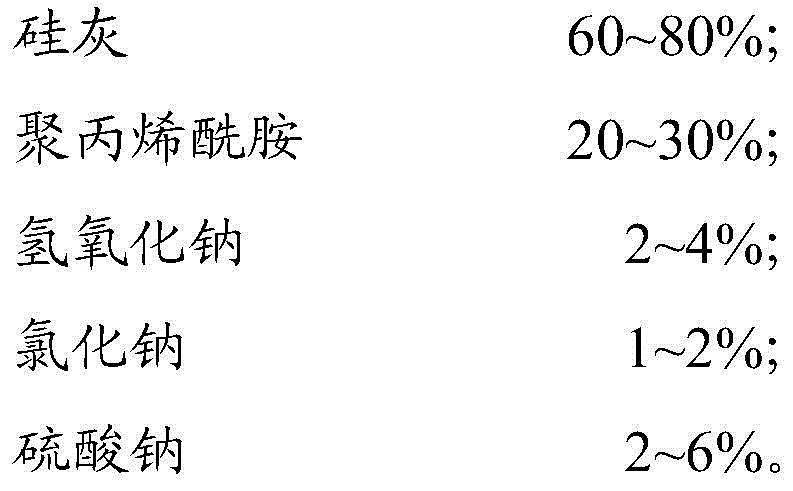

[0021] Step 10, prepare raw materials according to the following weight percentages, the sum of the content percentages of each raw material is 100%: silica fume 60-80%, polyacrylamide 20-30%, sodium hydroxide 2-4%, sodium chloride 1 ~2%, sodium sulfate 2~6%;

[0022] Step 20, dry the silica fume and polyacrylamide first, then add them to the mill, and grind for 20 to 30 minutes;

[0023] Step 30: Next, add sodium hydroxide, sodium chloride and sodium sulfate into the mill, grind and mix evenly, and then discharge.

[0024] Wherein, the mill is a ball mill, a column mill, a rod mill or a tube mill.

Embodiment 1

[0026] Example 1: Add silica fume and polyacrylamide to the mill after drying and metering, and grind for 20 to 30 minutes, then add sodium hydroxide, sodium chloride, and sodium sulfate measured according to the formula, and grind and mix evenly. Parts by weight are: 60 kg of silica fume, 30 kg of polyacrylamide, 3 kg of sodium hydroxide, 2 kg of sodium chloride, and 5 kg of sodium sulfate. Mix them uniformly to obtain the special additive for permeable concrete of the present invention.

Embodiment 2

[0027] Example 2: Add silica fume and polyacrylamide to the mill after drying and metering, and grind for 20 to 30 minutes, then add sodium hydroxide, sodium chloride, and sodium sulfate measured according to the formula, and grind and mix evenly. Parts by weight are: 68kg of silica fume, 25kg of polyacrylamide, 2kg of sodium hydroxide, 1kg of sodium chloride, and 4kg of sodium sulfate. Mix them uniformly to obtain the special additive for permeable concrete of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com