Preparation method and application of phosphorus-magnesium-based cement concrete coating protective material

A technology for cement concrete and protective materials, applied in the field of anti-corrosion coating materials, can solve the problems of inconspicuous improvement in crack resistance, mechanical properties and impermeability of concrete, unfavorable for large-scale popularization and utilization, and inability to meet the expected value of compacting agent, etc. To achieve the effect of short curing time, inhibition of cracking and improvement of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

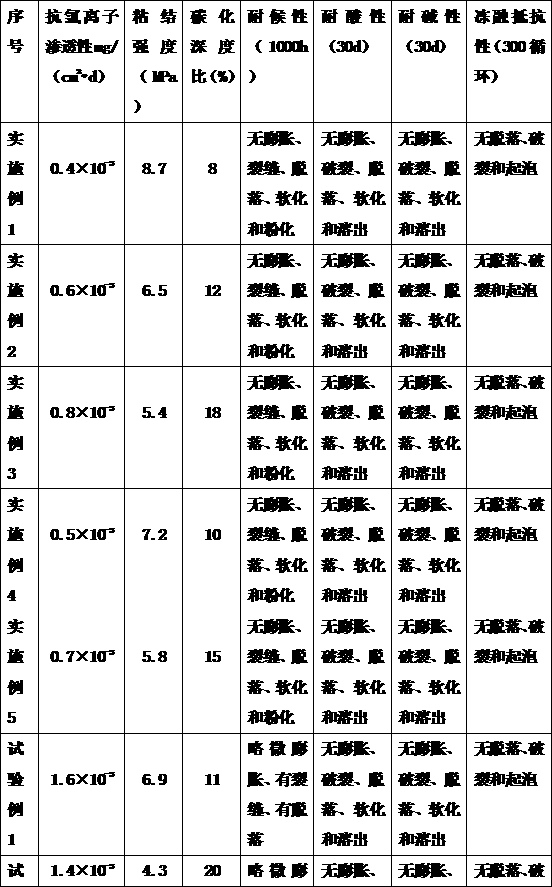

Examples

preparation example Construction

[0075] In yet another specific embodiment of the present invention, the preparation method of the above-mentioned phosphorus-magnesium-based cement concrete coating protective material is provided, comprising the following steps:

[0076] (1) Powder preparation: Weigh magnesium compound, salt-resistant compacting agent, mineral admixture, high-efficiency water reducer, composite retarder, finely ground phosphate, quartz sand, fiber, water-resistant agent, alkaline pH stabilizer, stir well and set aside;

[0077] (2) Mixing with water: Mix the prepared powder with water at a ratio of 1:0.12-0.2 and stir to form a slurry.

[0078] In yet another specific embodiment of the present invention, the application of the phosphorus-magnesium-based cement concrete coating protective material in the field of concrete coating protection in construction engineering is provided.

[0079] Specifically, the application method is to mix and stir the phosphorus-magnesium-based cement concrete c...

Embodiment 1

[0082] A preparation method of a phosphorus-magnesium-based cement concrete coating protective material, comprising the steps of:

[0083] (1) Powder preparation: Weigh 90 parts of magnesium compound according to the above ratio (component ratio: 80 parts of dead-burned magnesium, 20 parts of magnesium hydroxide), 50 parts of salt-resistant compacting agent (component ratio: ultrafine powder 70 parts of body, including 50 parts of water slag micropowder, 50 parts of gypsum powder; 15 parts of triethanolamine, 5 parts of naphthalene-based superplasticizer, 10 parts of sodium tripolyphosphate), 35 parts of mineral admixture (component ratio: magnesium 70 parts of base desulfurization fly ash, 15 parts of silica fume, nano-SiO 2 15 parts), 2 parts of high-efficiency water reducer (component ratio: 60 parts of polyether, 40 parts of polyacrylate), 15 parts of composite retarder (component ratio: 65 parts of borax, 25 parts of urea, 10 parts of boric acid parts), 25 parts of finel...

Embodiment 2

[0086] A preparation method of a phosphorus-magnesium-based cement concrete coating protective material, comprising the steps of:

[0087] (1) Powder preparation: Weigh 75 parts of magnesium compound according to the above ratio (component ratio: 50 parts of dead-burned magnesium, 50 parts of magnesium hydroxide), 35 parts of salt-resistant compacting agent (component ratio: ultrafine powder 55 parts of body, including 60 parts of silica fume powder, 40 parts of gypsum powder; 25 parts of triethanolamine, 10 parts of naphthalene-based water reducer, 10 parts of sodium tripolyphosphate), 30 parts of mineral admixture (component ratio: magnesium 55 parts of base desulfurization fly ash, 25 parts of silica fume, nano-SiO 2 20 parts), 1.5 parts of high-efficiency water reducer (component ratio: 50 parts of polyether, 50 parts of polyacrylate), 10 parts of composite retarder (component ratio: 55 parts of borax, 30 parts of urea, 15 parts of boric acid parts), 15 parts of finely gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com