A fiber woven mesh reinforced tailings solidified filling structure and its filling process

A fiber woven mesh and fiber technology, which is used in fillings, mining equipment, earth-moving drilling, etc., can solve the problems of high cost of cement use, poor plastic deformation ability, low long-term strength, etc., and achieve convenient and convenient construction, small deformation, Less restrictive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

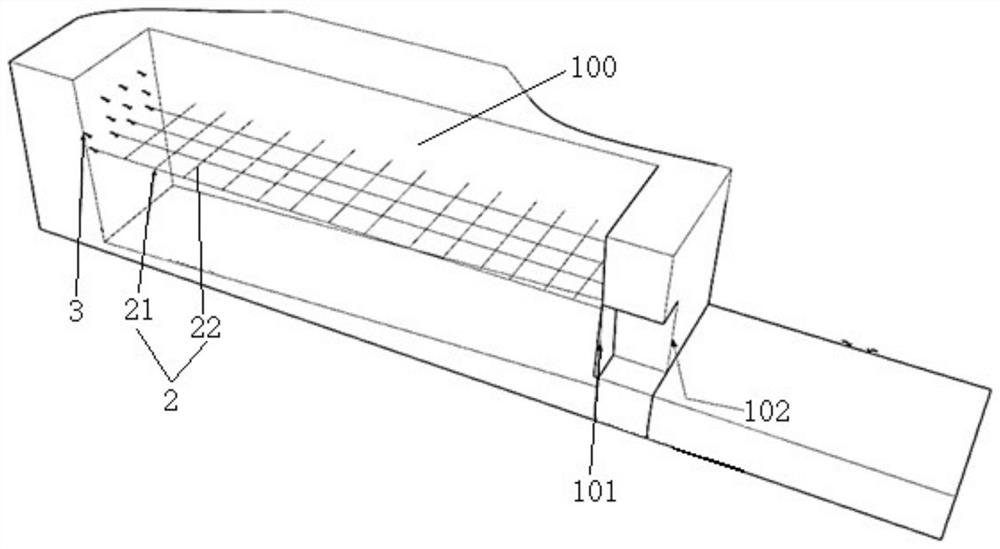

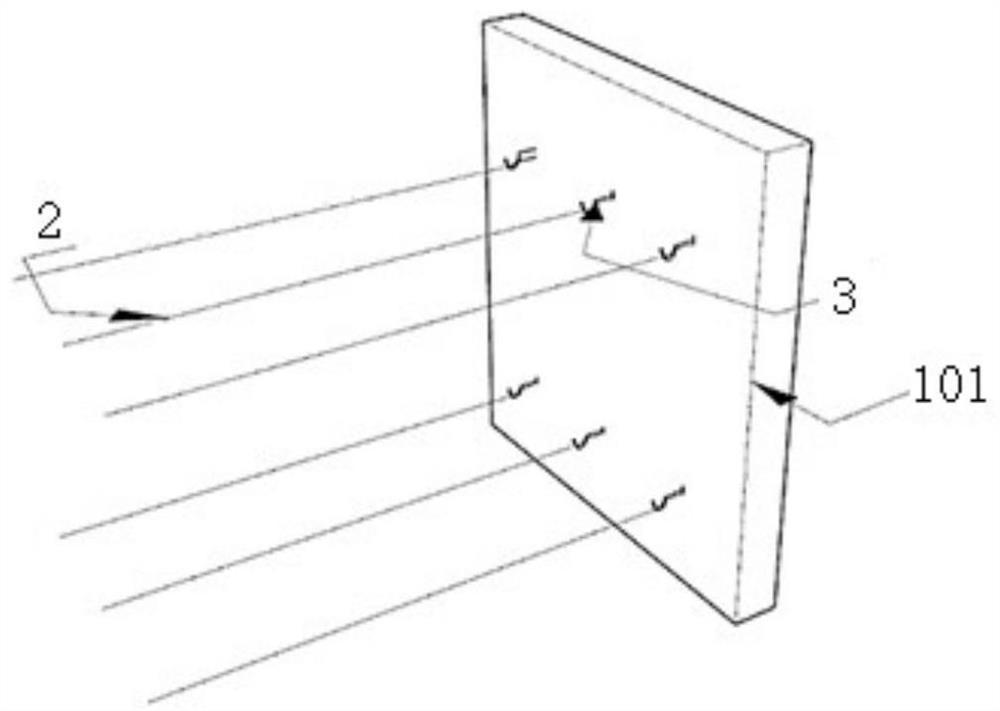

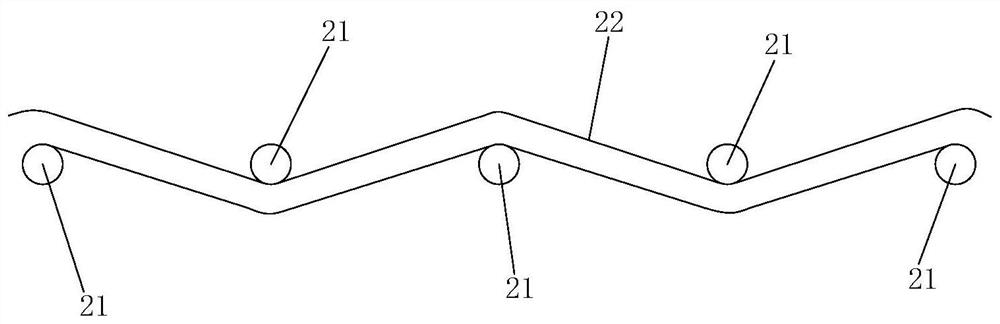

[0029] see figure 1 , in the gob shown in the illustration, the filling method of using fiber braided net to strengthen the solidification of tailings is a specific embodiment of the present invention. In the goaf, tailings are used for filling, and several layers of fiber braiding are embedded inside the formed filling body. The fiber woven net is woven into a net through fiber monofilament 2. In this embodiment, the fiber woven net is cross-formed by several transverse fibers 21 and some longitudinal fibers 22, and the transverse fibers 21 and longitudinal fibers 22 of the fiber woven net boundary are The ends are respectively fixed on the surrounding rock walls of the goaf, and the transverse fibers 21 and longitudinal fibers 22 are used as fiber monofilaments of the fiber woven net, which are fixed by hooks 3 anchored on the surrounding rock walls of the goaf, and filled in the gaps of the fiber woven net. The tailings filling solidifies to form a filling body.

[0030] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com