Large-dosage fly ash concrete and preparation method thereof

A fly ash and concrete technology, applied in the field of concrete and civil construction materials, can solve the problems of low chemical activity and low strength, and achieve the effects of promoting dispersion and reaction, improving strength and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

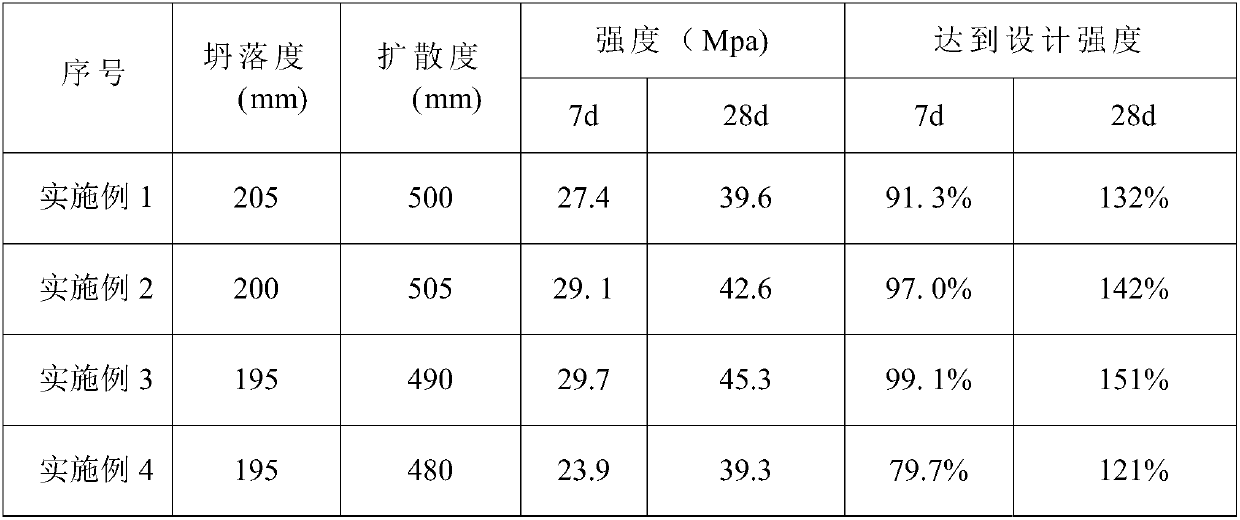

Embodiment 1

[0028] The preparation method of the modified reinforcing agent is as follows: (1) the mixture of 6.67 kg of bentonite and 3.33 kg of attapulgite is dried and dehydrated at 150 degrees Celsius, and then calcined and activated at 400 degrees Celsius for 6 hours; (2) the bentonite and attapulgite are activated for 6 hours; The soil mixture is uniformly mixed with 2kg sodium sulfate and 2kg calcium hydroxide powder; (3) 1.12kg triethanolamine maleate and 1.12kg calcium lignosulfonate are dissolved in 3.3 g of water and configured into a solution, and under stirring conditions, this The solution is evenly added to the mixture of sodium sulfate, calcium hydroxide and soil, and the mixture is continued to stir for 10 minutes, and then allowed to stand for 6 hours to form a multifunctional modified reinforcing agent for large-volume fly ash concrete.

[0029] Add 140kg PO 42.5 ordinary Portland cement, 265kg secondary fly ash, 45kg slag powder, 50kg modified reinforcing agent, 1010kg ...

Embodiment 2

[0031] The preparation method of the modified reinforcing agent is as follows: (1) the mixture of 5.00kg bentonite and 5.00kg attapulgite is dried and dehydrated under the condition of 150 degrees Celsius, and then calcined and activated at 600 degrees Celsius for 3 hours; (2) the bentonite and attapulgite are activated for 3 hours; The soil mixture is uniformly mixed with 2kg sodium sulfate and 2kg calcium hydroxide powder; (3) 1.12kg triethanolamine maleate and 1.12kg calcium lignosulfonate are dissolved in 3.3 g of water and configured into a solution, and under stirring conditions, this The solution is evenly added into the mixture of sodium sulfate, calcium hydroxide and soil, and the mixture is continued to stir for 10 minutes, and then allowed to stand for 9 hours to make a multifunctional modified reinforcing agent for large-volume fly ash concrete.

[0032] Add 170kg PO 42.5 ordinary Portland cement, 215kg secondary fly ash, 55kg slag powder, 45kg modified reinforcing ...

Embodiment 3

[0034] The preparation method of the modified reinforcing agent is as follows: (1) the mixture of 3.33 kg of bentonite and 6.67 kg of attapulgite is dried and dehydrated at 150 degrees Celsius, and then calcined and activated at 800 degrees Celsius for 2 hours; (2) the bentonite and attapulgite are activated for 2 hours; The soil mixture is uniformly mixed with 2kg sodium sulfate and 2kg calcium hydroxide powder; (3) 1.12kg triethanolamine maleate and 1.12kg calcium lignosulfonate are dissolved in 3.3 g of water and configured into a solution, and under stirring conditions, this The solution is evenly added to the mixture of sodium sulfate, calcium hydroxide and soil, and the mixture is continued to stir for 10 minutes, and then allowed to stand for 6 hours to form a multifunctional modified reinforcing agent for large-volume fly ash concrete.

[0035] 190kg PO 42.5 ordinary Portland cement, 195kg secondary fly ash, 65kg slag powder, 40kg modified reinforcing agent, 1100kg grav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com