A kind of highly stable non-alkali and chlorine-free liquid accelerator and preparation method thereof

A liquid accelerator and stable technology, applied in the field of highly stable non-alkali and chlorine-free liquid accelerator and its preparation, can solve the problems of large strength loss, poor stability, and strong corrosion in the later period, and achieve long storage time , good stability and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

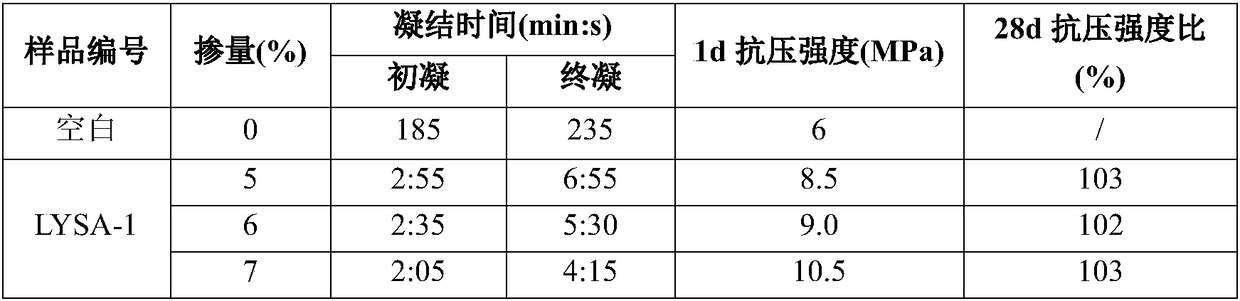

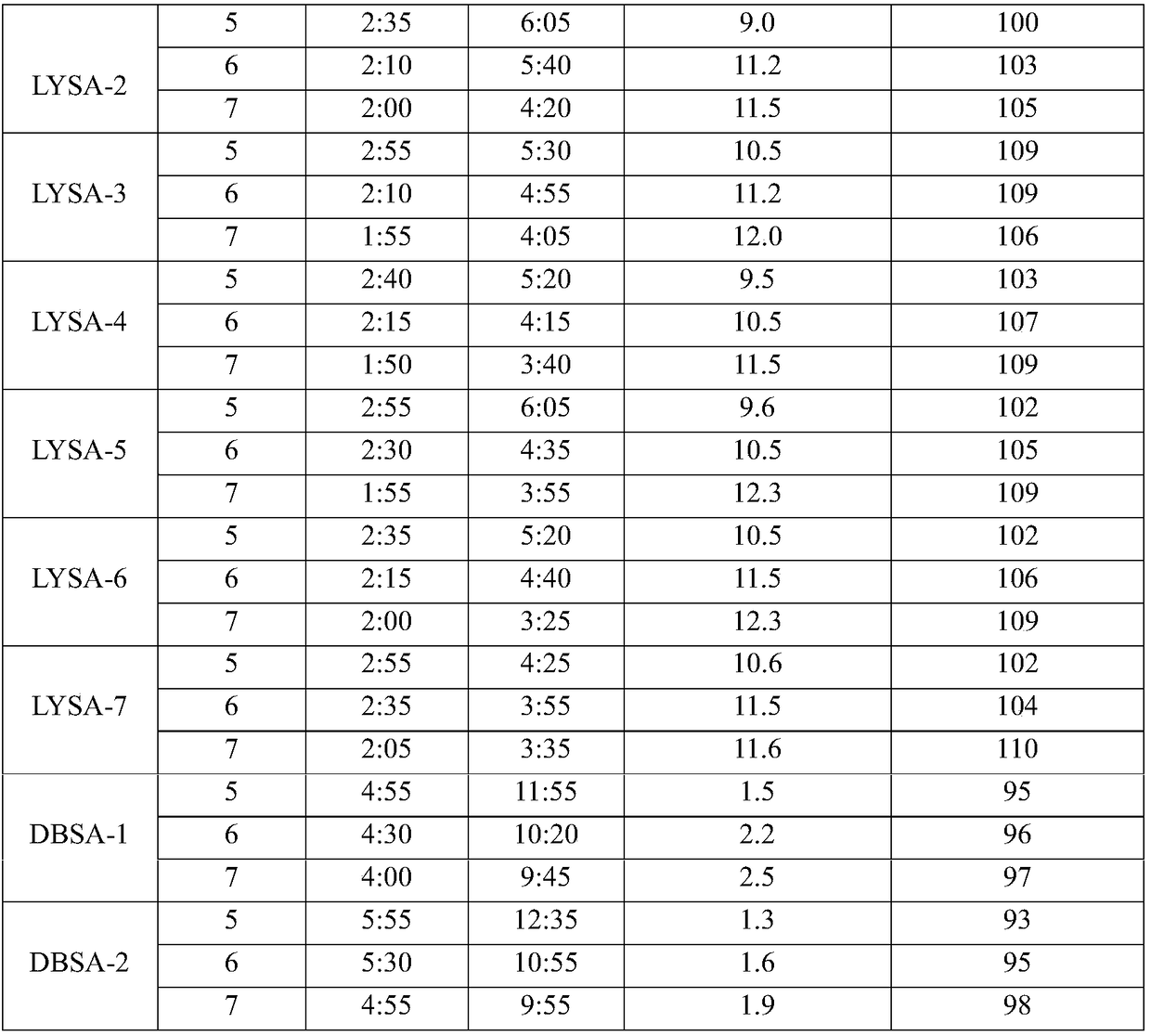

Examples

Embodiment 1

[0028] The preferred embodiment 1 of the present invention provides a highly stable alkali-free and chlorine-free liquid quick-setting admixture, which is composed of the following raw material components in parts by weight: 47 parts of aluminum sulfate octahydrate, 3.5 parts of sodium fluoride, and 44.2 parts of deionized water Parts, 1 part of Tween-20, 0.5 part of 18-crown-6 and 2 parts of hydroxyethylidene diphosphate, 0.2 part of polyacrylamide (molecular weight 5 million) aqueous solution, 0.6 part of diethanolamine, 1 part of 85% phosphoric acid.

[0029] At the same time, this embodiment also provides the preparation method of the above-mentioned highly stable alkali-free and chlorine-free liquid quick-setting admixture, which is specifically as follows: firstly, 47 parts of aluminum sulfate octahydrate and 3.5 parts of sodium fluoride are dissolved in 44.2 parts at 75°C. After dissolving in ionized water, add 1 part of Tween-20, stir and react for 0.5h, then add 0.5 part ...

Embodiment 2

[0031] The preferred embodiment 2 of the present invention provides a highly stable alkali-free and chlorine-free liquid quick-setting admixture, which is composed of the following raw material components in parts by weight: 50 parts of aluminum sulfate octahydrate, 5 parts of magnesium sulfate, and 35.3 parts of deionized water , Tween-80 2 parts, 18-crown-62 parts, amino trimethylene phosphonic acid 3 parts, polyacrylamide (molecular weight 8 million) aqueous solution 0.4 parts, triethanolamine 0.8 parts, p-toluene sulfonic acid 1.5 parts.

[0032] At the same time, this embodiment also provides a preparation method of the above-mentioned highly stable alkali-free and chlorine-free liquid quick-setting admixture, which is specifically as follows: first dissolve 50 parts of aluminum sulfate octahydrate and 5 parts of magnesium sulfate in 35.3 parts of deionized at 80°C In water, after the dissolution is complete, add 2 parts of Tween-80, stir and react for 1h, then add 2 parts of...

Embodiment 3

[0034] The preferred embodiment 3 of the present invention provides a highly stable alkali-free and chlorine-free liquid quick-setting admixture, which is composed of the following raw material components in parts by weight: 55 parts of aluminum sulfate octahydrate, 6 parts of ferrous sulfate, and 30.15 parts of deionized water Parts, 1 part of Tween-20, 1 part of Tween-80, 1 part of hydroxyethylidene diphosphate, 3 parts of amino trimethylene phosphonic acid, 0.6 part of polyacrylamide (molecular weight 10 million) aqueous solution, diethanol monoisopropyl 1 part of alcohol amine, 1.25 parts of p-toluene sulfonic acid.

[0035] At the same time, this embodiment also provides a method for preparing the above-mentioned highly stable alkali-free and chlorine-free liquid quick-setting admixture. Specifically, at 85° C., firstly, 55 parts of aluminum sulfate octahydrate and 6 parts of ferrous sulfate are dissolved in 30.15 parts of ferrous sulfate. After dissolving completely in ioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com