A low-heat cement that can efficiently utilize industrial waste gypsum

A technology of industrial waste gypsum and low-heat cement, applied in the field of cement materials, can solve the problems of rare production and application, difficulty in meeting the construction speed, low early strength of low-heat cement, etc., to overcome the low early strength, realize resource utilization, Good early strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

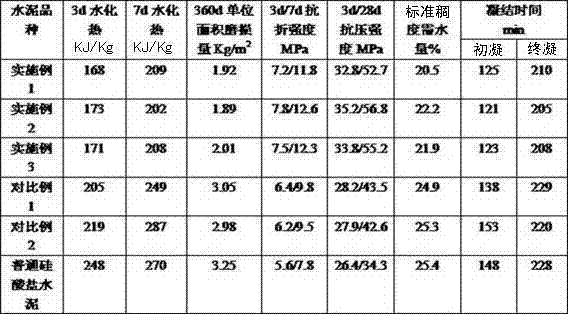

Examples

Embodiment 1

[0018] A low-heat cement capable of efficiently utilizing industrial waste gypsum, the preparation method of which is as follows:

[0019] 1. Preparation of cement raw meal:

[0020] Dosing according to the following mass parts: 55 parts of limestone, 0.5 part of bauxite, 5 parts of clay, 0.5 part of sulfuric acid slag, 0.2 part of fluorite, 3 parts of barium slag, 8 parts of processed industrial waste gypsum, and various The components are uniformly mixed and ground to 150-200 mesh to obtain cement raw meal. The treatment method of the treated industrial waste gypsum is as follows: drying at a high temperature of 350° C. for 30 minutes.

[0021] 2. Preparation of cement clinker

[0022] The mixed cement raw meal is placed in a rotary kiln for calcination, the calcination temperature is 1330°C, and the calcination time is 100min to obtain cement clinker;

[0023] 3. Preparation of Cement

[0024] Take 70 parts of burnt cement clinker, add 20 parts of industrial waste gypsu...

Embodiment 2

[0026] A low-heat cement capable of efficiently utilizing industrial waste gypsum, the preparation method of which is as follows:

[0027] 1. Preparation of cement raw meal:

[0028] Dosing according to the following mass parts: 75 parts of limestone, 3 parts of bauxite, 15 parts of clay, 1.5 parts of sulfuric acid slag, 0.6 part of fluorite, 8 parts of barium slag, 10 parts of processed industrial waste gypsum, various The components are uniformly mixed and ground to 150-200 mesh to obtain cement raw meal. The treatment method of the treated industrial waste gypsum is: drying at a high temperature of 350° C. for 40 minutes.

[0029] 2. Preparation of cement clinker

[0030] Put the mixed cement raw meal in a rotary kiln for calcination, the calcination temperature is 1350°C, and the calcination time is 90min to obtain cement clinker;

[0031] 3. Preparation of Cement

[0032] Take 80 parts of burnt cement clinker, add 15 parts of industrial waste gypsum and 0.5 part of re...

Embodiment 3

[0034] A low-heat cement capable of efficiently utilizing industrial waste gypsum, the preparation method of which is as follows:

[0035] 1. Preparation of cement raw meal:

[0036] Dosing according to the following mass parts: 90 parts of limestone, 4.5 parts of bauxite, 15 parts of clay, 1.5 parts of sulfuric acid slag, 0.6 part of fluorite, 8 parts of barium slag, 10 parts of processed industrial waste gypsum, and various The components are uniformly mixed and ground to 150-200 mesh to obtain cement raw meal. The treatment method of the treated industrial waste gypsum is: drying at a high temperature of 350° C. for 45 minutes.

[0037] 2. Preparation of cement clinker

[0038] Put the mixed cement raw meal in a rotary kiln for calcination, the calcination temperature is 1350°C, and the calcination time is 90min to obtain cement clinker;

[0039] 3. Preparation of Cement

[0040] Take 85 parts of burnt cement clinker, add 20 parts of industrial waste gypsum and 0.6 part o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com