Preparation method and application of composite magnesium oxide expanding agent

A magnesium oxide and composite technology, which is applied in the field of preparation of special functional materials for concrete, can solve problems such as low ability to compensate shrinkage, difficult-to-harden concrete, and failure strength, and achieve good expansion efficiency, increased long-term strength, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Composite magnesium oxide expansion agent is prepared according to the following steps:

[0024] (1) Dolomite and serpentine are used as raw materials, wherein the MgO content in dolomite is not less than 15%; the MgO content in serpentine is not less than 30%, Al 2 o 3 +Fe 2 o 3 The content is not higher than 15%; grind dolomite and serpentine so that the mass fraction of the 80 μm sieve of the raw material powder after grinding is less than 3%; fully mix dolomite and serpentine powder so that Ca and Si in the mixed powder The molar ratio is (1.9-2.0):1.

[0025] (2) Put the mixed powder obtained in step (1) into a kiln for firing, the calcination temperature is 1050°C, and the calcination time is 1 hour; after the calcination is completed, it is quenched in the air and avoids contact with water vapor; finally ground, and made If the mass fraction of the 80 μm sieve of the powder is less than 10%, the high-activity composite magnesium oxide expansion agent is obtai...

Embodiment 2

[0028] The difference from Example 1 is that the calcination temperature is 1100° C., and a composite magnesium oxide expansion agent with medium activity is obtained.

[0029] When mixing concrete in a ready-mixed concrete factory, mix 15-20 parts of composite magnesium oxide expansion agent, 10-30 parts of fly ash, 5-20 parts of finely ground mineral powder, 5-10 parts of silicon powder, silicic acid 20-60 parts of salt cement is blended as a cementitious material, the water-to-cement ratio is 0.3-0.55, and coarse and fine aggregates are added according to the concrete mix ratio design specification JGJ55 to prepare concrete. Cured under the conditions of 40°C and RH greater than 90%, the expansion time of the medium-active composite magnesium oxide expansion agent is 42 days; the expansion rate can reach the standard of 0.02%-0.05% for the long-term stability of the plastic sand.

Embodiment 3

[0031] The difference from Example 1 is that the calcination temperature is 1150° C., and a composite magnesium oxide expansion agent with low activity is obtained.

[0032] When mixing concrete in a ready-mixed concrete factory, mix 15-20 parts of composite magnesium oxide expansion agent, 10-20 parts of fly ash, 5-30 parts of ground mineral powder, 5-10 parts of limestone powder, silicic acid 20-60 parts of salt cement is blended as a cementitious material, the water-to-cement ratio is 0.3-0.55, and coarse and fine aggregates are added according to the concrete mix ratio design specification JGJ55 to prepare concrete. Cured under the conditions of 40°C and RH greater than 90%, the expansion time of the low-activity composite magnesium oxide expander is 120 days. The expansion rate can reach the standard of 0.03%-0.07% of the long-term stability limit expansion rate of the mortar.

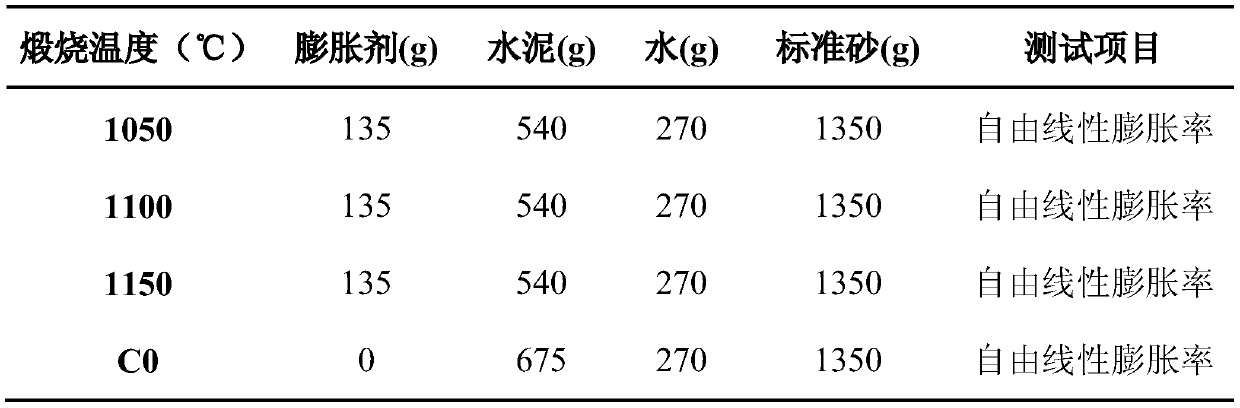

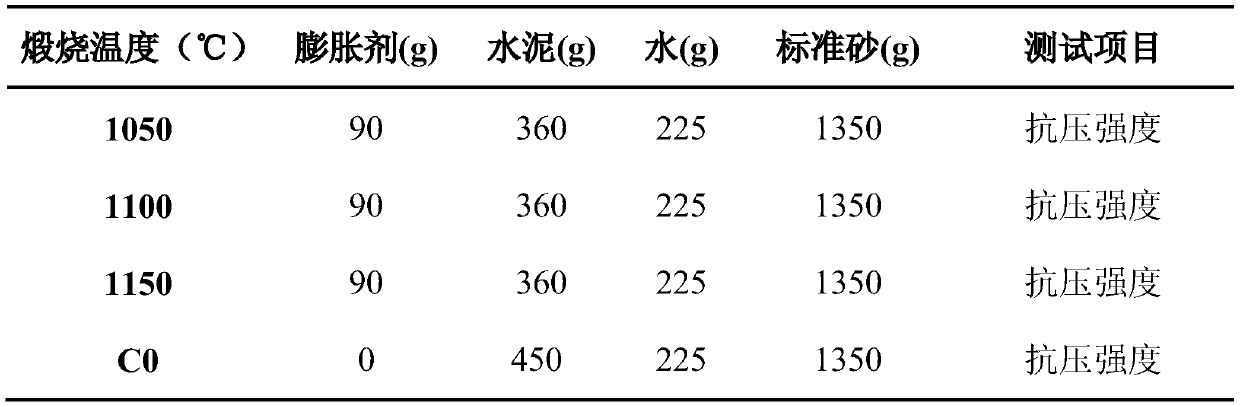

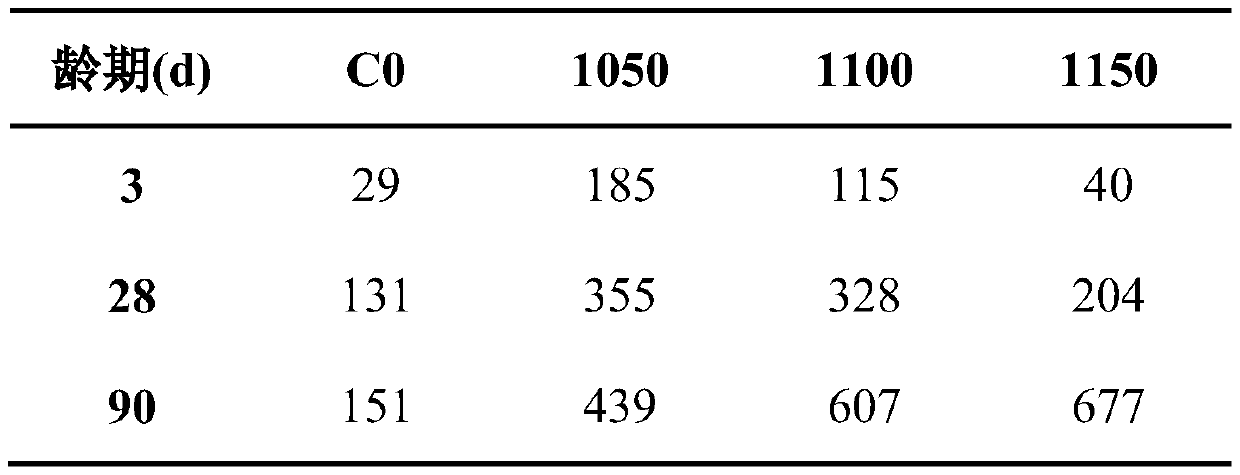

[0033]According to the standard test method of free linear expansion rate (the sum of expansi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com