A modified calcium aluminophosphate mineral

A technology of modifying calcium aluminophosphate and calcium aluminophosphate, which is applied in the field of cement materials, can solve problems such as low early strength, large volume shrinkage, and difficulty in meeting performance and construction requirements of Portland cement, achieving significant energy saving and consumption reduction , The effect of reducing the synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

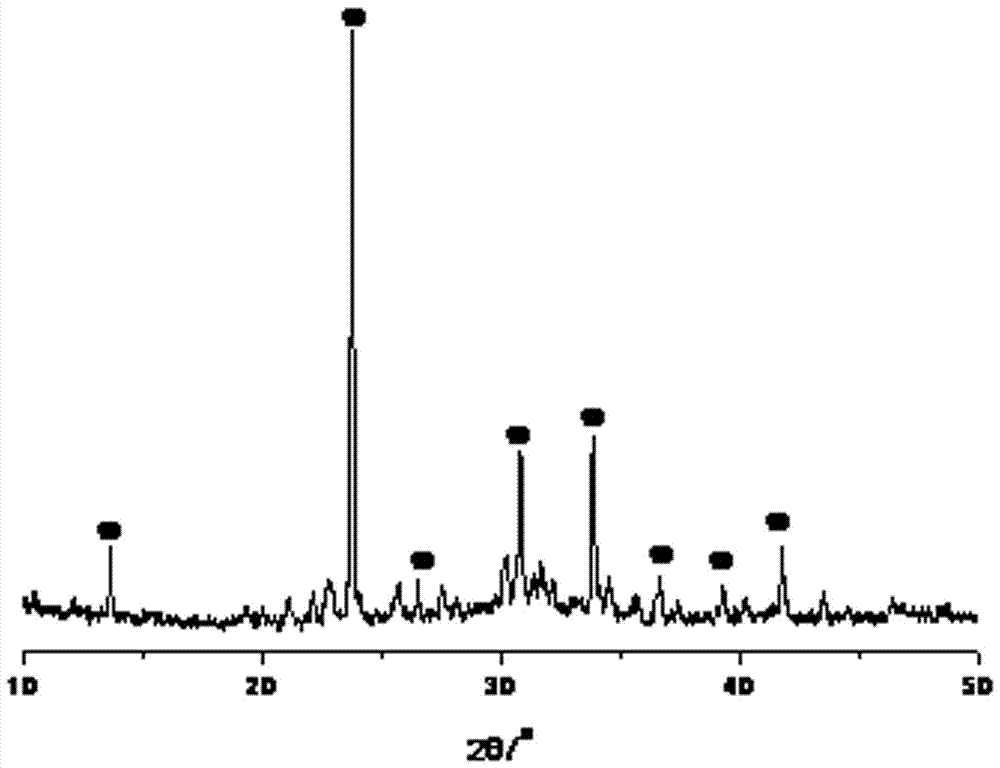

Embodiment 1

[0028] A modified calcium aluminophosphate mineral, which is obtained by calcining raw materials, modifiers and mineralizers at a temperature of 1450 ° C, holding time for 3 hours, and rapidly cooling to room temperature;

[0029] The weight ratio of the raw meal, modifier and mineralizer is 100:7:5;

[0030] The mole percentage of each oxide in the raw material is: SiO 2 11.9, P 2 o 5 2.6, A1 2 o 3 46.1, CaO39.4;

[0031] The modifier is SrO;

[0032] MgO in the mineralizer: ZnO: Fe 2 o 3 The weight ratio is 1:1.5:1.

[0033] A modified calcium aluminophosphate mineral is prepared by the following steps:

[0034] 1) Grind various cement raw materials, modifiers and mineralizers separately, pass through a 200-mesh sieve, and the sieve residue is <5%;

[0035] 2) Mix the ground cement raw materials according to the mole percentage of each oxide in the raw meal, add modifiers and mineralizers according to the weight ratio, and add water according to the water-materi...

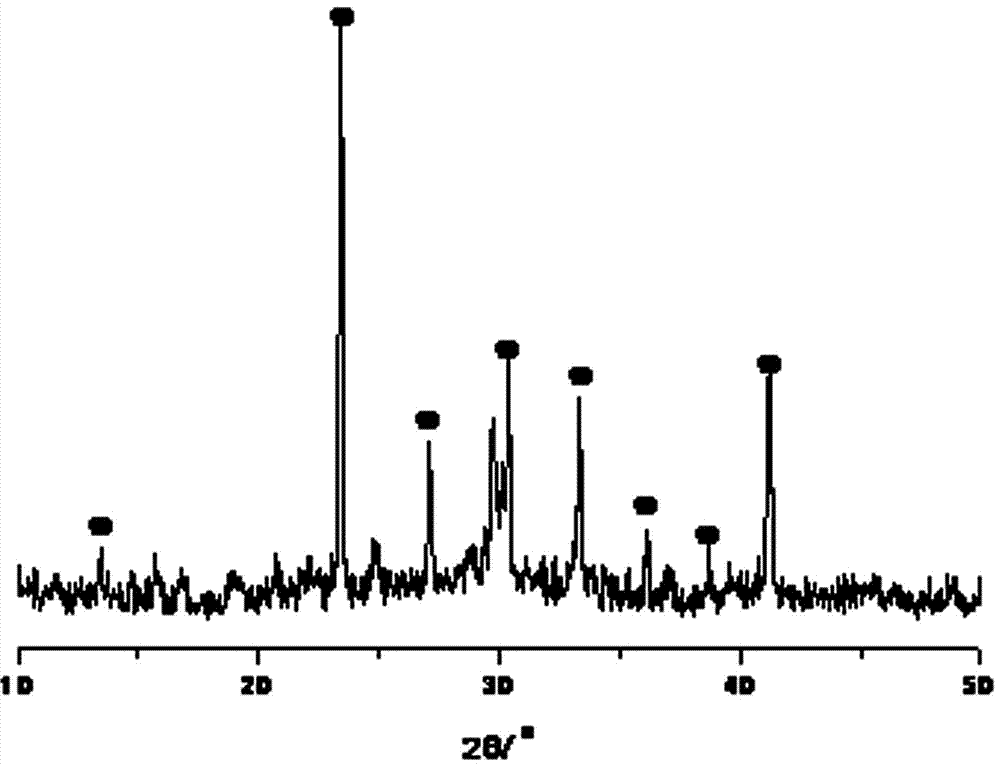

Embodiment 2

[0040] A modified calcium aluminophosphate mineral, which is obtained by calcining raw materials, modifiers and mineralizers at a temperature of 1500 ° C, holding time for 2 hours, and rapidly cooling to room temperature;

[0041] The weight ratio of the raw meal, modifier and mineralizer is 100:11:4;

[0042] The mole percentage of each oxide in the raw material is: SiO 2 10.2, P2 o 5 3.9, A1 2 o 3 42.6, CaO43.3;

[0043] The modifier is BaO;

[0044] MgO in the mineralizer: ZnO: Fe 2 o 3 The weight ratio is 1:1.2:1.5.

[0045] A kind of preparation method of modified calcium aluminophosphate mineral is the same as embodiment 1.

[0046] According to the mechanical property test, the compressive strength of clean paste is 30MPa for 1d, 65MPa for 3d, 95MPa for 7d, 120MPa for 28d and 130MPa for 90d.

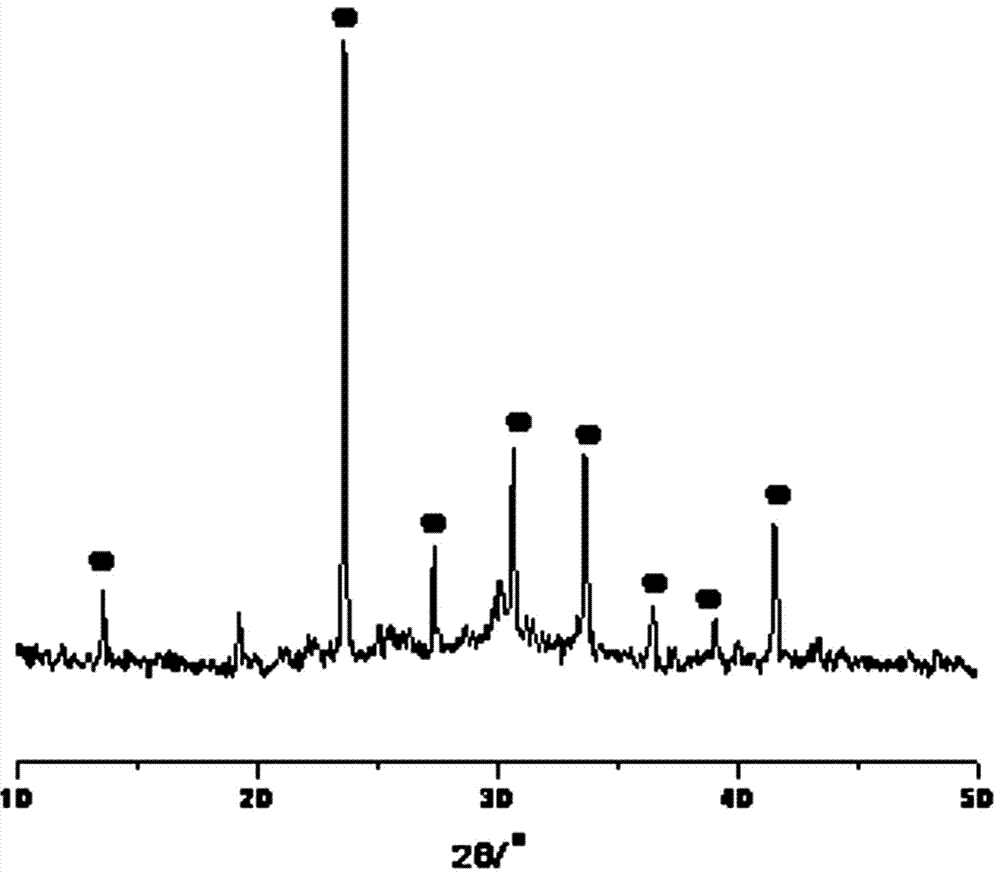

Embodiment 3

[0048] A modified calcium aluminophosphate mineral, which is obtained by calcining raw materials, modifiers and mineralizers at a temperature of 1550 ° C, holding time for 1 hour, and rapidly cooling to room temperature;

[0049] The weight ratio of the raw meal, modifier and mineralizer is 100: 14: 3;

[0050] The mole percentage of each oxide in the raw material is: SiO 2 8.5, P 2 o 5 5.0, A1 2 o 3 39.3, CaO 47.2;

[0051] The modifier is BaO;

[0052] MgO in the mineralizer: ZnO: Fe 2 o 3 The weight ratio is 1:1:2.5.

[0053] A kind of preparation method of modified calcium aluminophosphate mineral is the same as embodiment 1.

[0054] According to the mechanical property test, the compressive strength of the clean pulp is 27MPa for 1d, 63MPa for 3d, 92MPa for 7d, 114MPa for 28d and 124MPa for 90d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com