Sand pulp concrete waterproof agent and method for making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

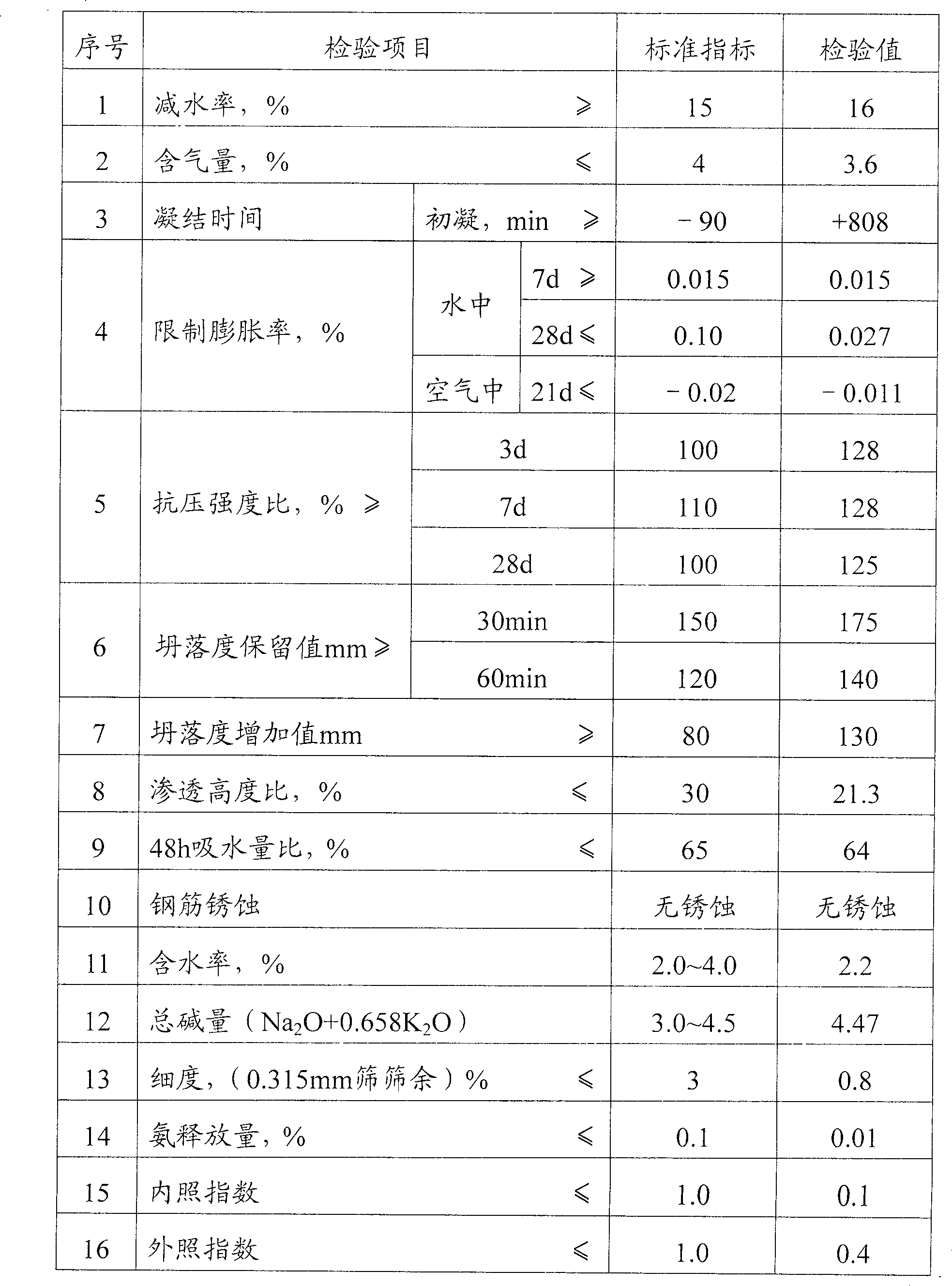

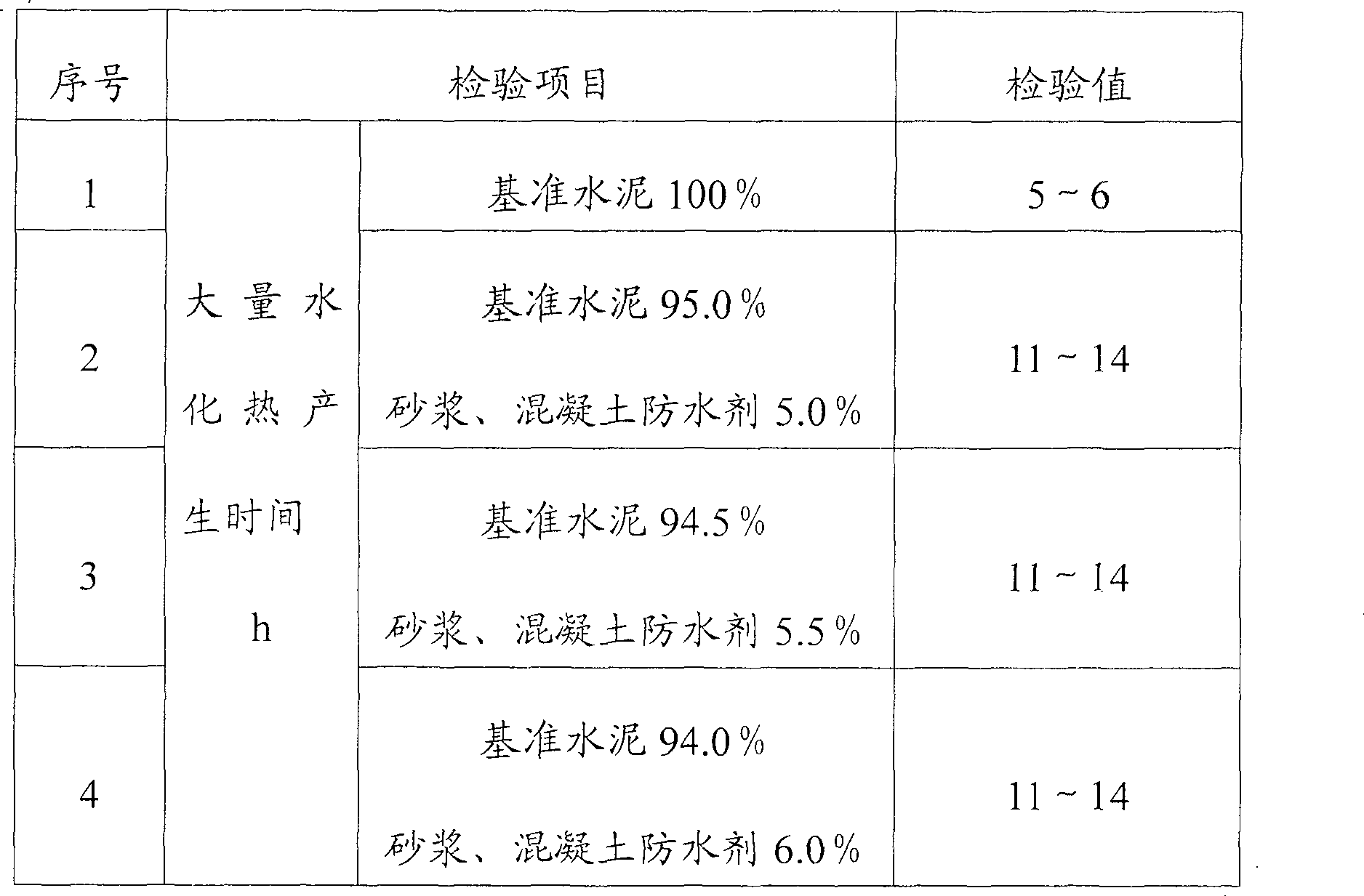

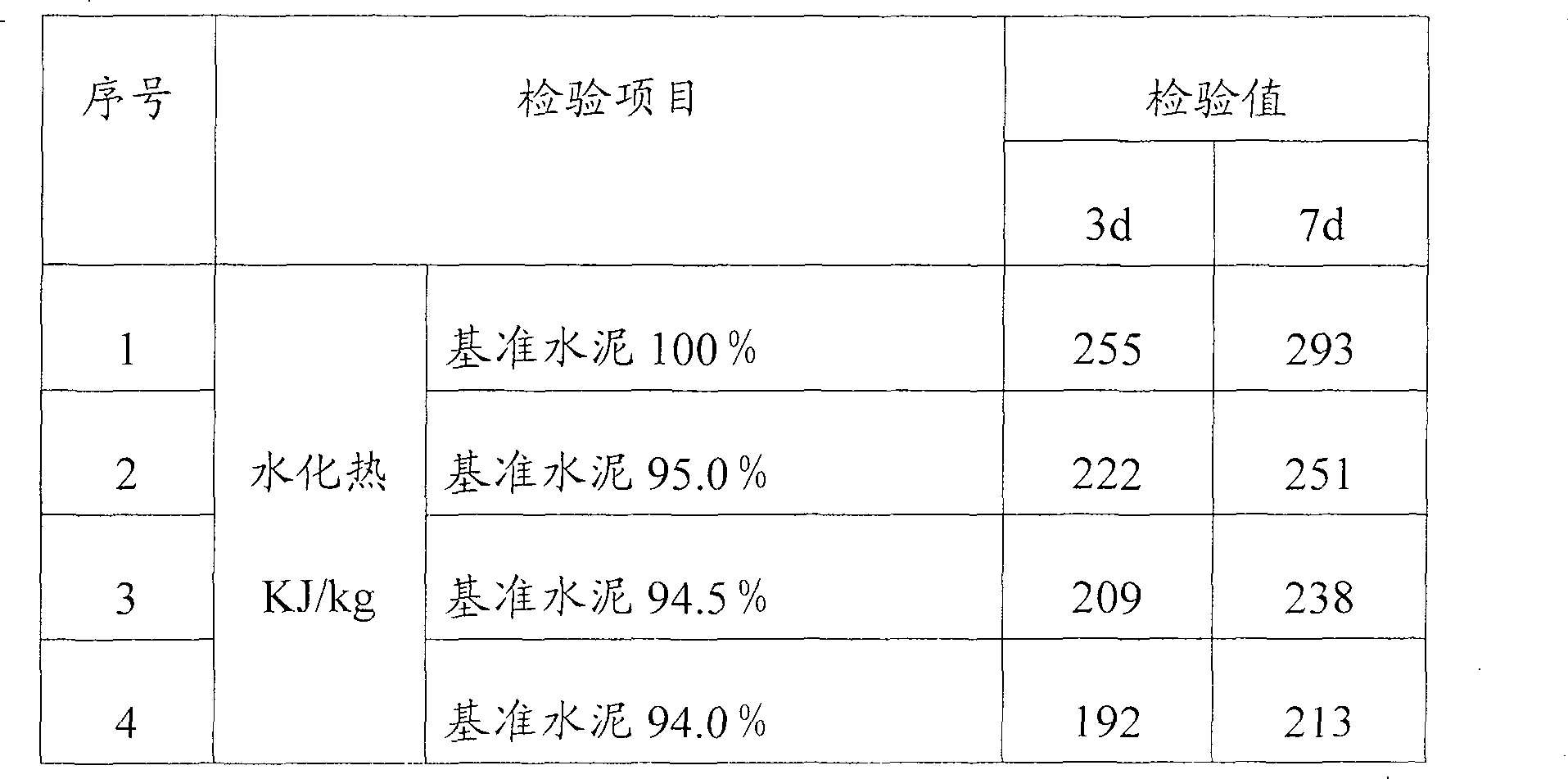

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Weigh 83 parts of activated zeolite powder by weight and place them in a mixer, then weigh 1 part of silane coupling agent, 4 parts of stearic acid, 0.03 parts of alkylphenol polyoxyethylene ether, and 7 parts of magnesium lime 3 parts of gypsum, 8 parts of polypropylene fiber, and then add the modifier—silane coupling agent, alkylphenol polyoxyethylene ether, and stearic acid to the activated zeolite powder in sequence and stir, the temperature is controlled at 150-210°C and stirring for 2 hours to form activated modified zeolite powder; then add weighed magnesia lime, gypsum and polypropylene fiber into the activated modified zeolite powder, and fully stir and mix to obtain mortar and concrete waterproofing agent.

[0027] The fineness of the activated zeolite powder in the present invention is preferably 260~500 meshes, and when the waterproofing agent dosage is 5% of cement consumption, the fineness of the activated zeolite powders is 350~500 meshes and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com