Water-quenched blast furnace slag for cement raw material and its screening method

A technology for cement raw materials and screening methods, applied in cement production, recycling technology and other directions, can solve the problems of low strength and slow strength, and achieve the effects of low initial strength, low hydration heating rate, and high long-term strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

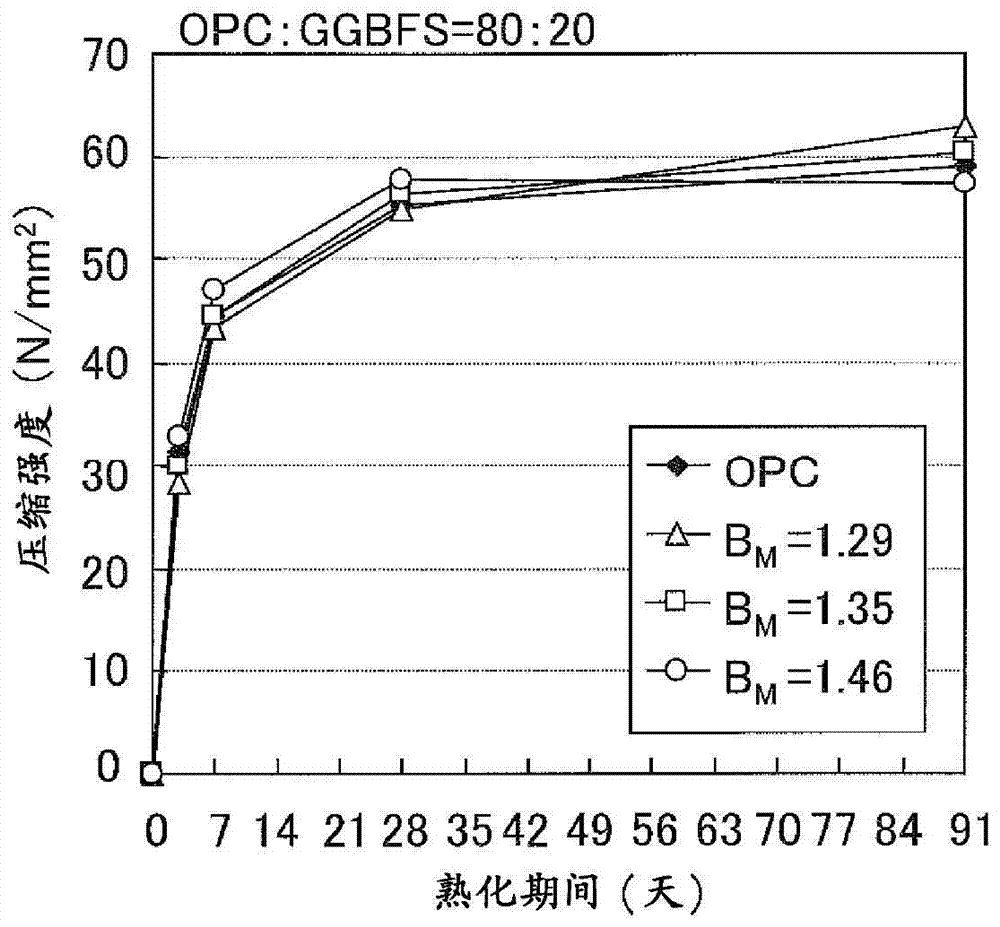

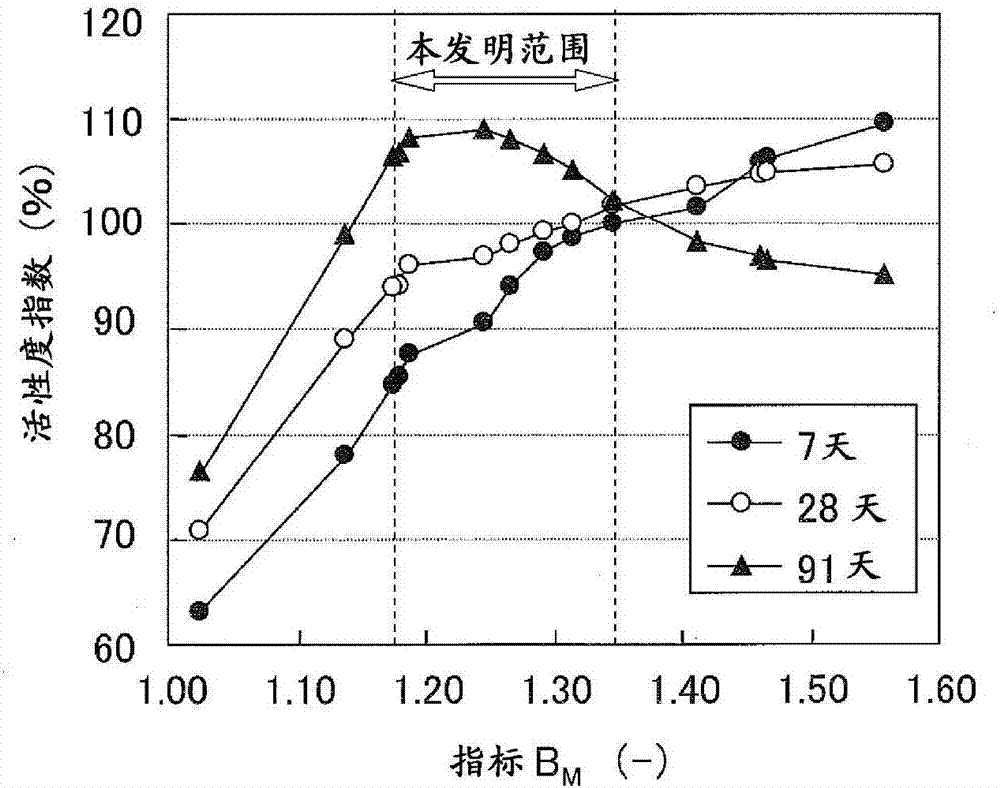

[0066] The effects of the present invention were confirmed by the following method using blast furnace quenched slag fine powder (GGBFS) produced in a fine powder manufacturing plant.

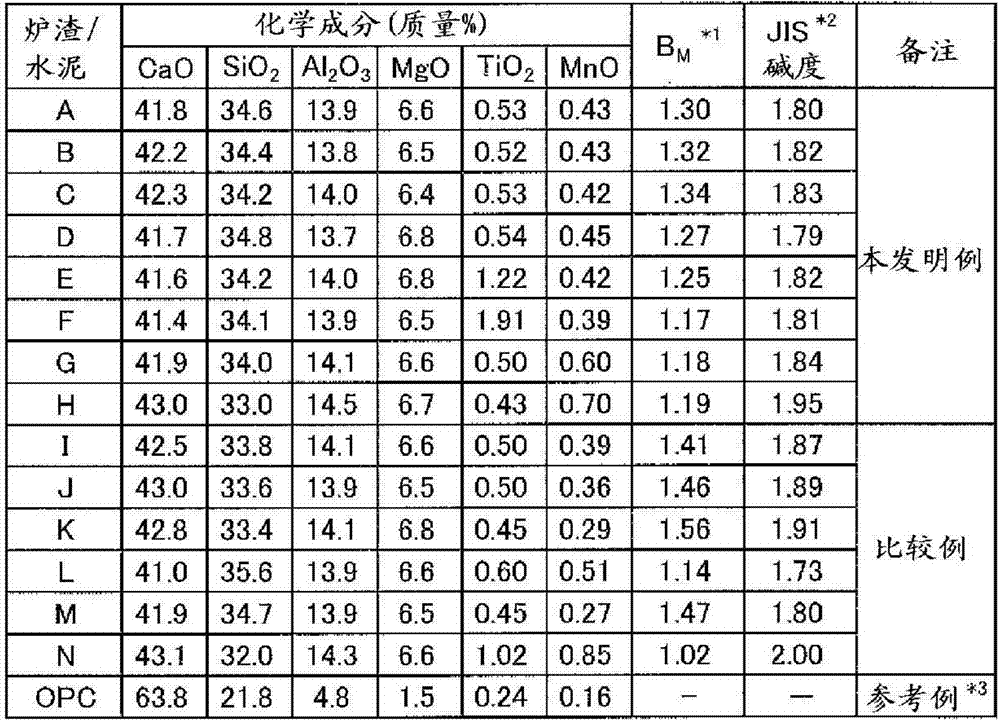

[0067] Blast furnace water-quenched slag produced every time the blast furnace is tapped is collected, quality control is carried out according to the chemical composition, and the blast furnace water-quenched slag with various chemical components shown in Table 1 is pulverized by the grinder of the fine powder manufacturing plant to produce blast furnace water Quenching the slag fine powder, and measuring the activity index of the mortar made of the obtained blast furnace water quenching slag fine powder.

[0068] [Table 1]

[0069]

[0070] *1)B M =(CaO+Al 2 o 3 +MgO) / SiO 2 -0.13×TiO 2 -MnO (among them, CaO, Al 2 o 3 , M g O, SiO 2 、TiO 2 , MnO is the content of each oxide contained in blast furnace water-quenched slag (mass %))

[0071] *2) JIS Alkalinity = (CaO+Al 2 o 3 +M ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com